Setup

WPP 15 TE | Version 1.06

9

7

Setup

The hydraulic workshop press must be set up and oper-

ated in dry, well-ventilated indoor areas only.

It must be positioned securely and set up on an even,

stable surface that is free from vibrations.

Make sure there is a sufficient amount of clearance on

each side and the work area is adequately lit.

8

Installation

The following parts of the hydraulic workshop press are

provided in disassembled condition in the cardboard

box:

- Crossbeam feet

- Press table

- Pump unit

- Pressure gauge

These parts must be assembled or converted and se-

cured with screws.

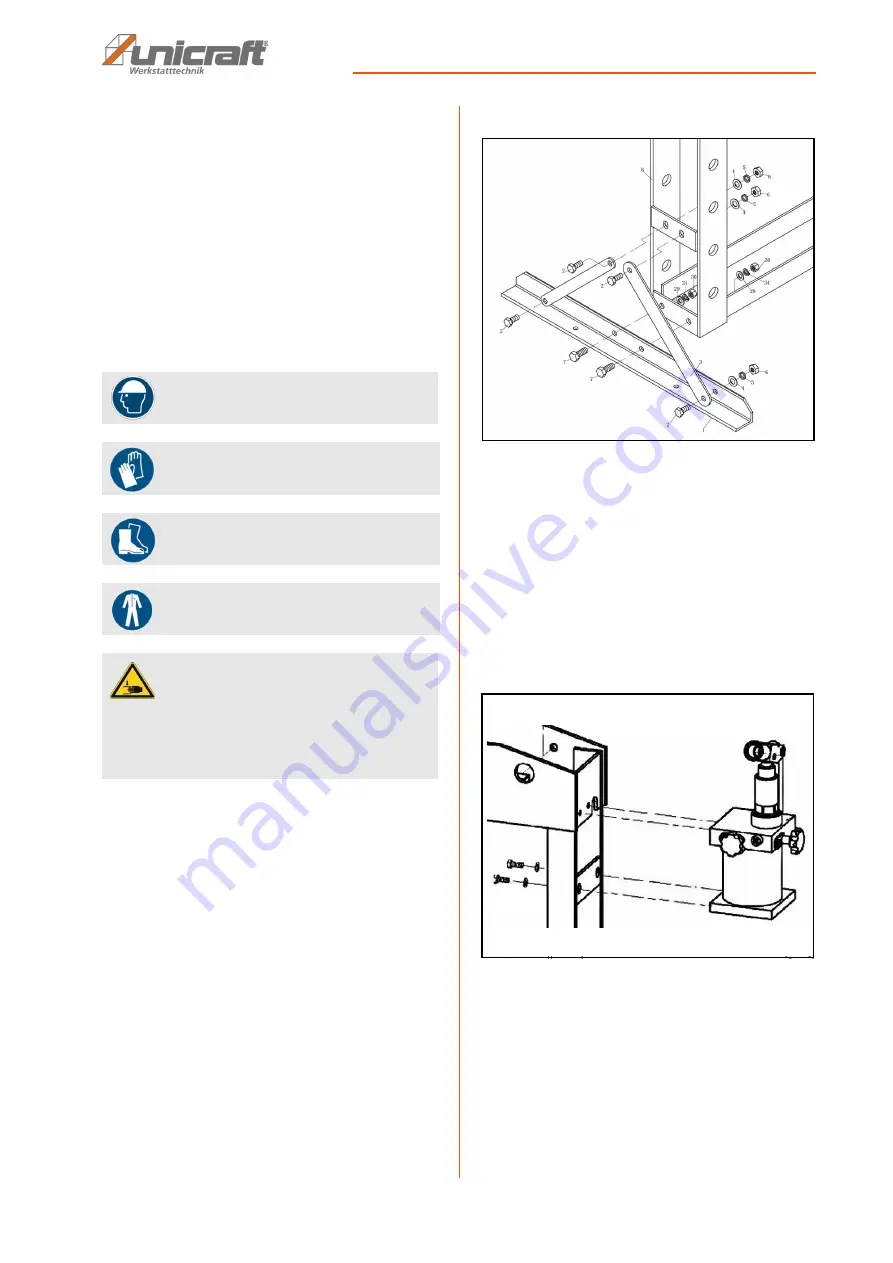

8.1 Installing crossbeam feet and press table

Fig. 5: Installing crossbeam feet

Step 1: secure the crossbeam feet and the two cross-

beams to both sides of the frame using the

screws, shims, spring washers and nuts

(see Fig. 5).

Step 2: insert the support bolts into the frame at the de-

sired height and secure them using the safety

splints. The position the press table onto the

support bolts in the frame.

8.2 Installing the pump unit

Fig. 6: Installing the pump unit

Step 1: screw the pump unit onto the outside of the

frame using the screws and shims (see Fig. 6).

Step 2: install the pressure lines.

Wear head protection!

Wear protective gloves!

Wear safety shoes!

Wear protective clothing!

ATTENTION!

Risk of pinching!

Risk of injury to fingers and hands caused by incor-

rect installation work on the workshop press.

- Keep in mind the workshop press' weight. Ensure

stable supports and support equipment.