OM-NGB 7

Installation

CAUTION

DO NOT LOCATE THE BOILER CABINET

DIRECTLY OVER A FLOOR DRAIN OR FLOOR

SINK. HUMIDITY OR WATER FROM WILL

DAMAGE ELECTRICAL.

IMPORTANT

IMPROPER DRAIN CONNECTION

WILL VOID WARRANTY.

Leave a two-inch air gap between the hose

and the building drain, and don’t allow

water traps in the line.

b.

Copies of the electrical schematic are located in the electrical enclosure

on the equipment and in this manual. In Canada, electrical service must

comply with the Canadian Electrical Code, CSA C22.1, Part 1, and/or

local codes.

3. Water Connection

a.

Cold water is supplied via a 1/2” NPT pipe connection at the rear of the

unit. A check valve (back siphonage device) must be installed in accord

with local plumbing codes.

b.

Water pressure should be between 30 and 60 PSI. If it is over 60 PSI,

a pressure regulator is required. A strainer screen at the connection is

also recommended, to trap any debris before it can enter the system.

c.

The boiler uses a maximum of 12.9 gallons of water per hour. Piping

should be sized to handle total water consumption.

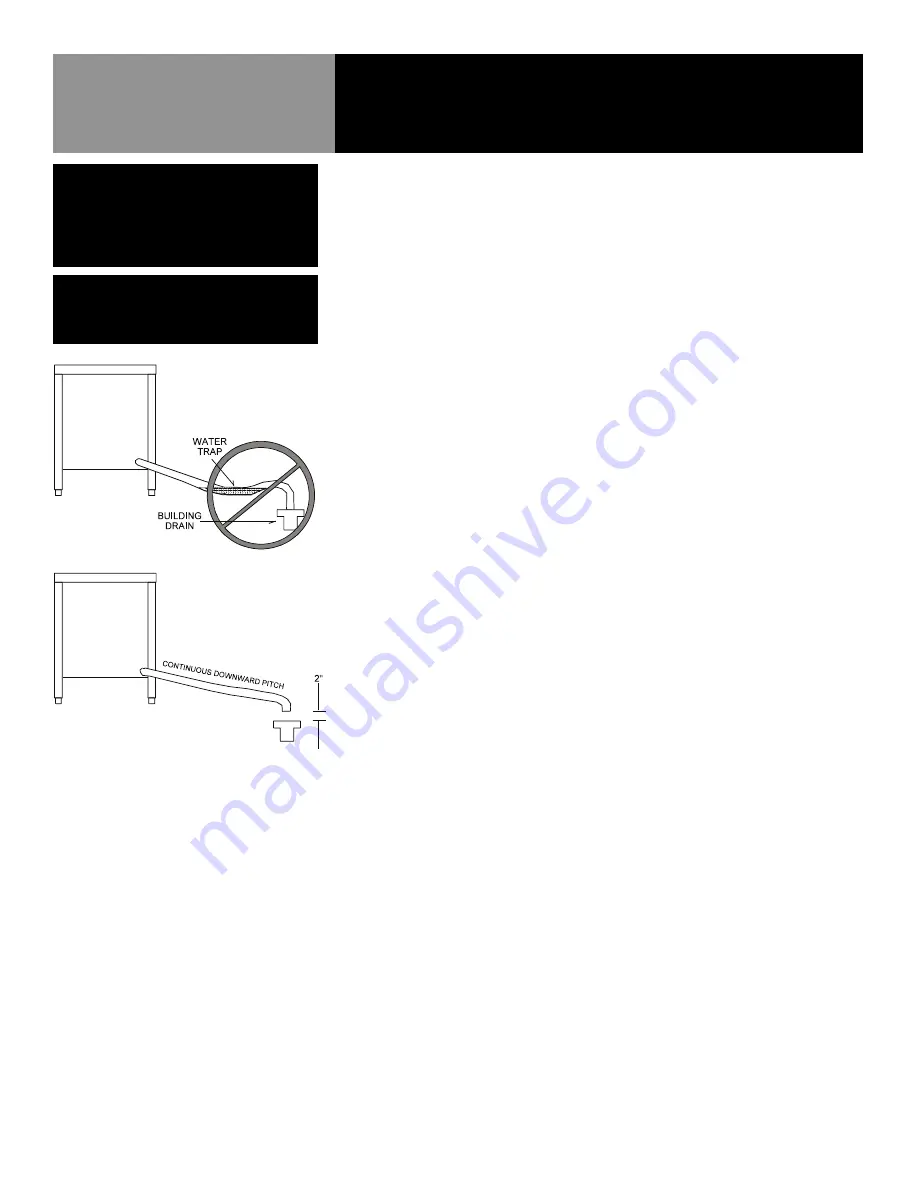

4. Drain Connection

a.

The drain connection is made at the rear of the unit with 1 - 1/4” NPT

pipe. DO NOT USE PLASTIC PIPE. DRAIN PIPING MUST WITHSTAND

STEAM AND BOILING WATER. Extend the drain piping to a nearby

floor drain. Piping of 1 - 1/4” NPT (or 1 - 1/2” NPT) is acceptable for

distances of six feet or less. If the distance to the drain is further than

six feet, use 2” NPT piping.

b.

The drain line must be installed with a constant downward pitch. Do

not permit any water traps in the line. DO NOT CONNECT THE LINE

DIRECTLY TO ANY BUILDING DRAIN. A vertical air gap of at least two

inches must be maintained between the drain line and the building

drain unless otherwise specified by local plumbing codes.