OM-DEEP WELL REFRIGERATOR SERIES 7

Operation

Allow unit to operate for approximately two (2) hours before placing in food.

AMBIENT CONDITIONS

Unit is designed for normal operating temperatures are between 70-100°F. Operating

outside of those temperatures may cause premature product wear or failure

Unified Brands has attempted to preset the temperature control to ensure that your

unit runs at an optimum temperature, but due to varying ambient conditions, including

elevation, food type and your type of operation, you may need to alter this temperature

using control adjustment until desired temperature is reached.

It is normal for the refrigerated deep well to develop an even layer of frost during

operation.

NOTE

: Keeping the sliding cover closed as much as possible will prevent

excessive frost buildup.

MORNING STARTUP

1. Cold pan cleaning may be performed at this time.

2. Turn on unit with switch located in the mechanical compartment.

3. Allow 30 minutes for the cold pan to cool down before loading product.

4. Load the product and proceed with food preparation.

NOTE

: Product entering the cold

pan must be at 40°F or less.

EVENING SHUT DOWN

Remove product from the cold pan at the end of the day’s preparation. The product may

be discarded or stored in any commercial refrigerator.

1. Turn off unit with switch located in the mechanical compartment. This will allow

unit to thaw which allows for better operation when starting up unit for next day

operation.

2. Unit cleaning may be performed at this time once the frost has melted off the

surface. NOTE: Water may form small pools and have to be pushed to the drain for

100% draining.

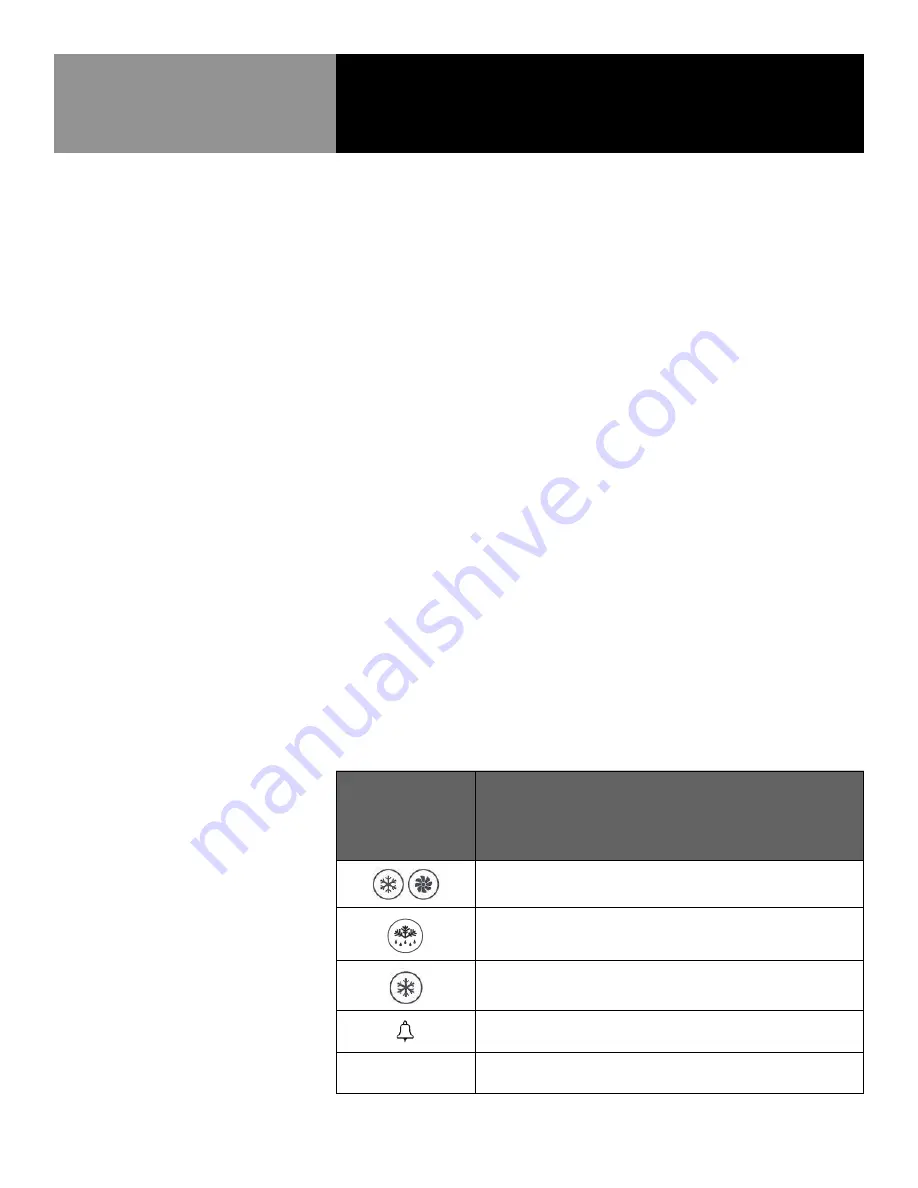

DANFOSS CONTROLLER OPERATION

LED

FUNCTION

Compressor energized

Defrost in progress

Fans delay after defrost completion

An alarm is occurring

ºC / ºF

Temperature unit