19

HYDRAULIC CONNECTIONS

(see also the enclosed installation drawings and hydraulic diagram)

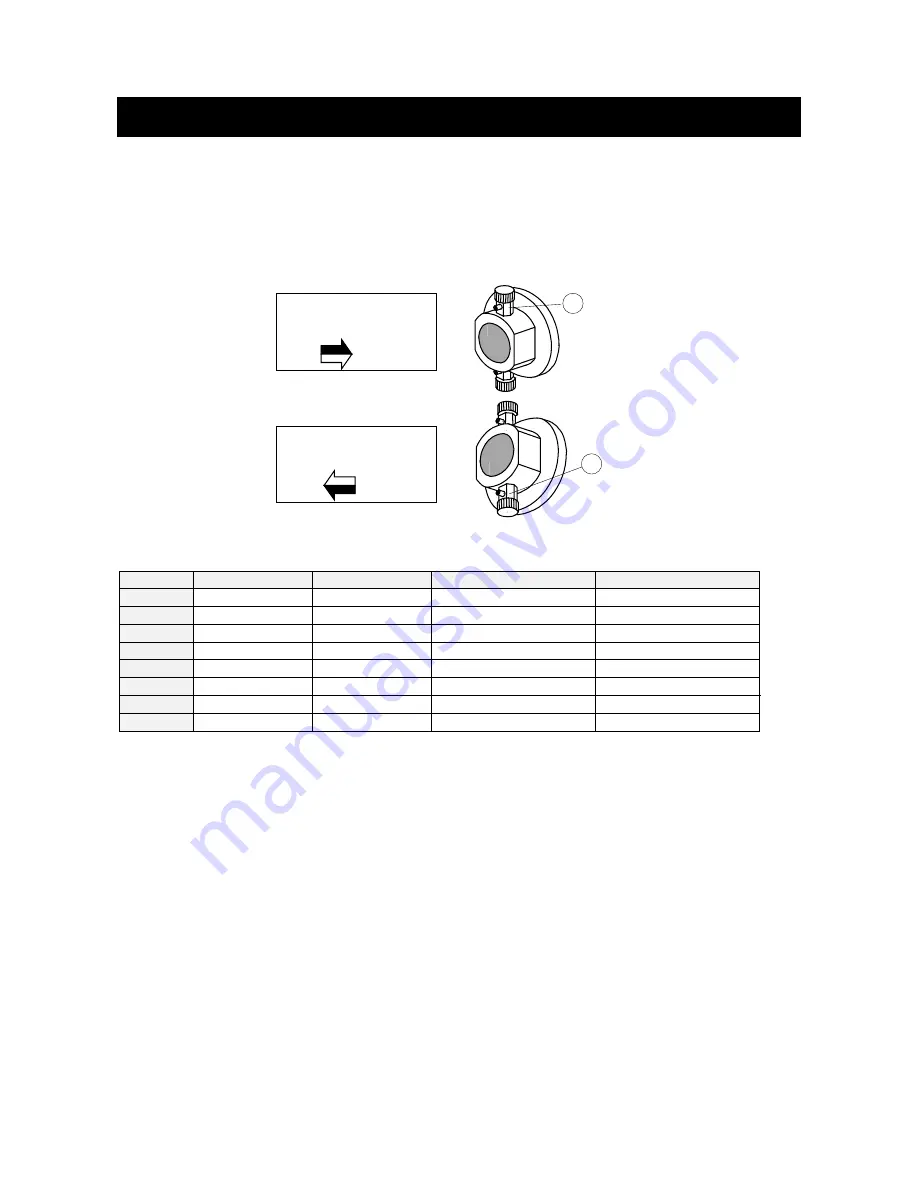

1) CHECK

that the section of the chilled water pipes and the power of the circulation pump fitted are

sufficient. An inadequate water flow significantly reduces the cooling capacity of the unit.

2) CHECK

the water intake/output directions. There are labels next to the intake, output and heat recovery

connections as shown in the diagram below. The bleed (S) and drain (V) valves are part of the special input

and output connections.

INGRESSO - INLET

EINGANG - ENTREE

ENTRADA

I

ev

USCITA - OUTLET

AUSGANG - SORTIE

SALIDA

U

ev

OUTPUT

CONNECTION

V

INTAKE

CONNECTION

S

ARA

Water Intake

Water Output

Heat recovery intake

Heat recovery output

00152

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

00182

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

00202

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

00232

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

00252

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

00302

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

00403

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

00504

Ø 2” GAS F.

Ø 2” GAS F.

Ø 1 1/4” GAS F.

Ø 1 1/4” GAS F.

3) CONNECT

the chiller using flexible tubes to stop the transmission of vibrations. Fit shut-off valves so that

the unit can be isolated from the water circuit;

4) INSULATE

the chilled water pipes to stop the formation of condensation;

5) FIT

temperature measuring points on the pipes near the intake and output connections;

6) INSTALL

a metal filter in the section of pipe next to the unit intake to prevent pieces of welding or flakes of

rust entering the heat exchanger.

7) PROVIDE

a discharge well near the output connection in case the unit needs to be emptied.

Summary of Contents for Aquaflair 00152

Page 47: ...47...