27

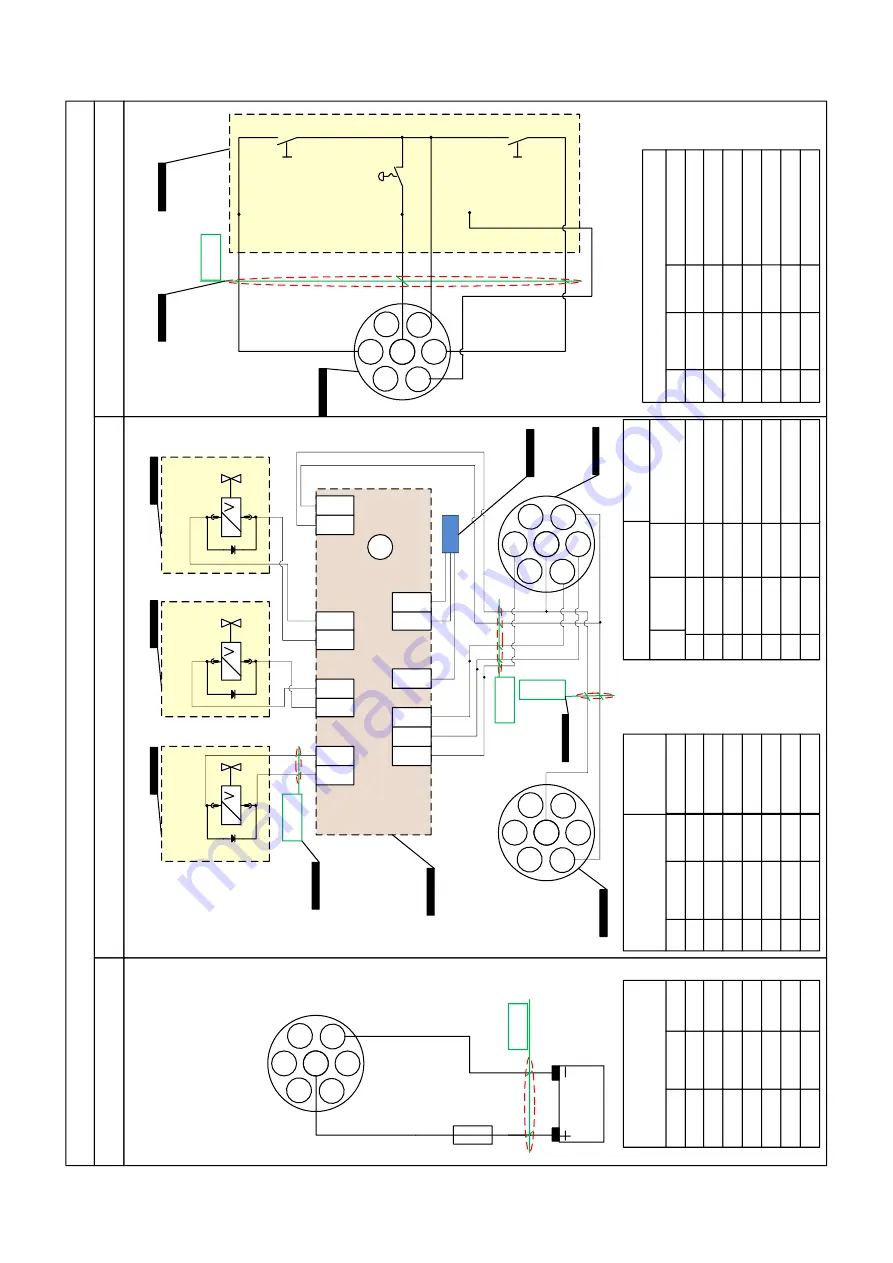

Version Hpro, Hpro+KS

1

2

3

4

5

6

7

10

A

1

2

V

A

cc

o

m

u

la

to

r

1

2

3

4

5

6

7

1

2

3

4

5

6

7

2

1

SO

C

K

ET

SO

C

K

ET

1

2

3

4

5

6

7

4

3

4

3

ST

O

P

5

×

1

,5

B

R

A

K

E

C

LU

TC

H

P

LU

G

+1

2

V

2

×

2

,5

B

R

A

K

E

1

3

9

1

0

1

1

TR

A

C

TO

R

W

IN

C

H

C

O

N

SO

LE

(H

p

ro

, H

p

ro

+K

S,

E

h

p

ro

+K

S)

SO

C

K

ET

N

o

.

1

2

3

4

5

6

7

M

ar

k

L

5

4

g

3

1

R

5

8

R

5

4

5

8

L

Li

n

ka

ge

/

/

M

A

SS

/

/

/

+1

2

V

P

LU

G

N

o

.

1

2

3

4

5

6

7

Li

n

ka

ge

/

/

M

A

SS

/

/

/

+1

2

V

SO

C

K

ET

N

o

.

1

2

3

4

5

6

7

Li

n

ka

ge

B

R

A

K

E

/

M

A

SS

C

LU

TC

H

P

er

m

an

en

t

/

+1

2

V

M

ar

k

L

5

4

g

3

1

R

5

8

R

5

4

5

8

L

M

ar

k

L

5

4

g

3

1

R

5

8

R

5

4

5

8

L

O

ŽI

Č

EN

JE

H

p

ro

–

S

M

A

R

T

2

/

Ye

llo

w

/g

re

en

3

4

/

1

O

ŽI

Č

EN

JE

(

V

TI

K

A

Č

)

H

p

ro

-

S

M

A

R

T

-

-

Ye

llo

w

/g

re

en

-

-

-

1

P

LU

G

N

o

.

1

2

3

4

5

6

7

Li

n

ka

ge

B

ra

ke

/

M

A

SS

cl

u

tc

h

P

er

m

an

en

t

/

+1

2

V

M

ar

k

L

5

4

g

3

1

R

5

8

R

5

4

5

8

L

O

d

2

0

1

5

gr

ay

-

b

ra

u

n

Ye

llo

o

w

/g

re

en

b

lu

e

-

b

la

ck

2

1

H

YD

R

O

M

O

TO

R

5

2

1

C

LU

TC

H

EL

EC

TR

O

N

IC

S

(0

3

1

7

)

1

0

1

7

6

1

6

PB1-V

PB2-D

PB3-D

PA7

0V

12V

12V

0V

PA0

0V

PA1

0V

PA2

0V

F2

A

Fu

se

2

×

1,5

P

LU

G

Ye

llo

w

/g

re

en

1

1

Ye

llo

w

/

gr

ee

n

2

3

4

5

×

0

,7

5

2

×

0

,7

5

2

4

6

7

8

0

V

4

3

P

er

m

an

en

t

b

la

ck

b

lu

e

b

ra

u

n

Se

n

so

r

1

2