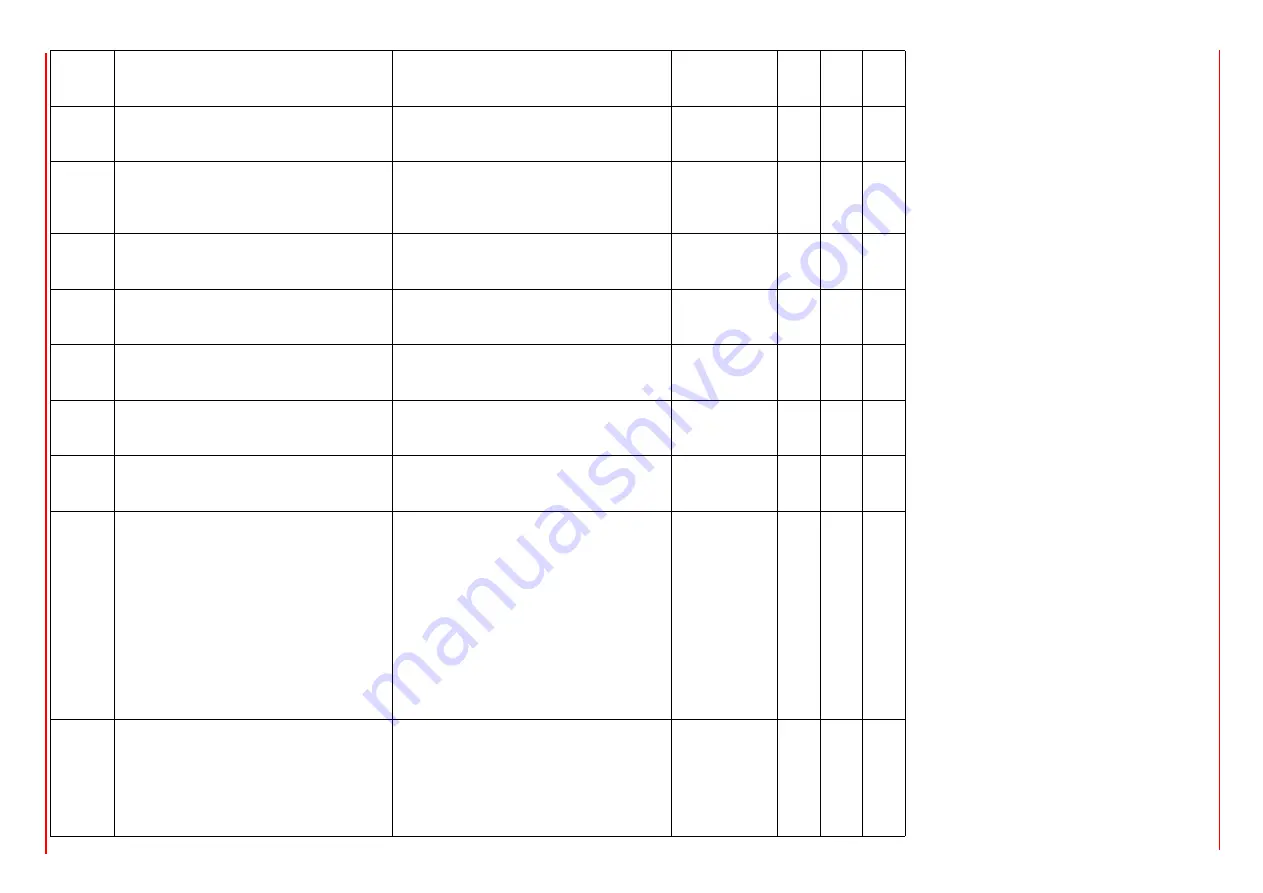

21

326

Combustibile 1 - Gas: tempo di preaccen-

sione (valore fabbrica = 2s - range imposta-

zione:0.2s - 60min)

Fuel 1 - Gas: Preignition time (default value =

2s - range: 0.2s - 60min)

OEM / Service

x

327

Combustibile 1 - Gas: tempo di sicurezza 1

(TSA1) (valore fabbrica = 3s - range impo-

stazione:0.2 - 10s)

Fuel 1 - Gas: Safety time 1 (TSA1) (default

value = 3s - range: 0.2 - 10s)

OEM

x

329

Combustibile 1 - Gas: tempo di risposta a

cadute di pressione entro TSA1 e TSA2

(valore fabbrica = 1.8s - range imposta-

zione:0.2s - 9.8s)

Fuel 1 - Gas: time to respond to pressure

faults in TSA1 e TSA2 (default value = 1.8s -

range: 0.2s - 9.8s)

OEM

x

330

Combustibile 1 - Gas: Intervallo 1 (valore

fabbrica = 2s - range impostazione:0.2s -

60min)

Fuel 1 - Gas: Interval 1 (default value = 2s -

range: 0.2s - 60min)

OEM / Service

x

331

Combustibile 1 - Gas: tempo di sicurezza 2

(TSA2) (valore fabbrica = 3s - range imposta-

zione:0.2 - 10s)

Fuel 1 - Gas: Safety time 2 (TSA2) (default

value = 3s - range:0.2 - 10s)

OEM

x

332

Combustibile 1 - Gas: Intervallo 2 (valore

fabbrica = 2s - range impostazione:0.2s -

60min)

Fuel 1 - Gas: Interval 2 (default value = 2s -

range:0.2s - 60min)

OEM / Service

x

333

Combustibile 1 - Gas: Tempo postcombu-

stione (valore fabbrica = 8s - range imposta-

zione:0.2s - 60s)

Fuel 1 - Gas: postcombustion time (default

value = 8s - range:0.2s - 60s)

OEM / Service

x

334

Combustibile 1 - Gas: Tempo postventila-

zione (valore fabbrica = 0.2s - range impo-

stazione:0.2s - 180min)

Fuel 1 - Gas: Postpurge time (default value =

0.2s - range:0.2s - 180min)

OEM / Service

x

336

Combustibile 1 - Gas: Pressostato gas di

minima (default = 1)

0 = inattivo

1 = pressostato gas di minima (a monte val-

vola V1)

2 = controllo perditavalvole via pressostato

(montato tra le valvole V1 e V2)

Fuel 1 - Gas: Pressure switch-min input

0 = inactive

1 = pressure switch-min (upstream of fuel

valve 1 (V1))

2 = valve proving via pressure switch-min

(between fuel valves 1 (V1) and 2 (V2))

OEM / Service

x

337

Combustibile 1 - Gas: Pressostato gas di

massima / ingressoPOC

0 = inattivo

1= pressostato gas di massima

2= POC

3 = pressostato controllo perdite

Fuel 1 - Gas: Pressure switch-max / POC

input

0 = inactive 1 = pressure switch-max

2 = POC

3 = pressure switch valve proving

x

Summary of Contents for E140X

Page 46: ......

Page 47: ......

Page 49: ...Service manual AZL2x LMV2x 3x Burner Management System M12916CD Rev 3 4 03 2023...

Page 56: ...8 Parameters level heating engineer...

Page 98: ...50 ERROR CODE TABLE...

Page 99: ...51...

Page 100: ...52...

Page 101: ...53...

Page 102: ...54...

Page 103: ...55...

Page 104: ...56...

Page 105: ...57...

Page 106: ...58...

Page 107: ...59...

Page 108: ...60...

Page 109: ...61...

Page 110: ...62...

Page 111: ...63...

Page 112: ...64...

Page 117: ......

Page 118: ......

Page 119: ......

Page 121: ...IG FU B...

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......