PART II: INSTALLATION

18

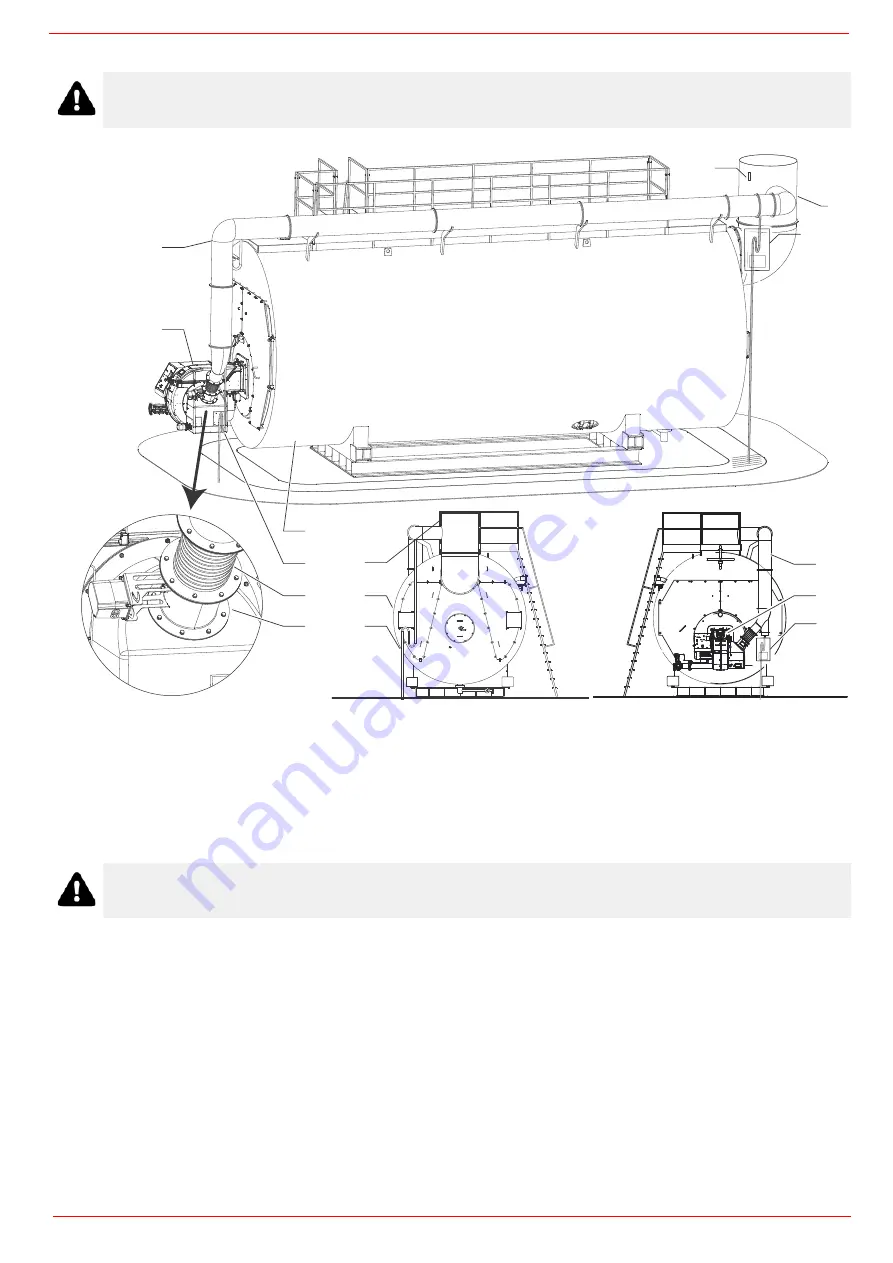

Sizing of the FGR pipe (FGR burners only)

1111

The temperature probe for flue gas temperature compensation must be installed on the chimney.

The internal diameter of the FGR conduit must be dimensioned considering a maximum speed of 10 m / s. Assume a volumetric flow

rate of recirculatig fluegases for the dimensioning equal to 20% of the comburent air flow.

Example:

Let’s say 4.816 kW is the maximum burner output:

required combustion air flow will then be 5.800 Stm

3

/h = 1,61 Stm

3

/s in standard conditions (15 °C; 1.013 mbar).

* FGR = Flue gas recirculation system

ATTENTION! Performance curve is obtained in a plant designed according to the following guidelines, size the

FGR pipe as per the example below.

ATTENTION! Pipe elbows increase pressure losses, so limit their use as much as possible.

Flue gas temperature:

150 °C or 150 + 273,15 = 423,15 K

Ambient temperature:

15 °C or 15 + 273,15 = 288,15 K

FGR flow for dimensioning:

1,61 x 20% = 0,322 Stm3 / s

FGR flow corrected for flue gas temperature:

0,322 x 423,15 / 288,15 = 0,473 m3 / s @ (t = 150 °C)

FGR pipe section:

0,473 m3/s / 10 m/s = 0,0473 m2

So in this example, pipe internal diameter must be larger than 245 mm to ensure proper FGR flow.

8

7

6

1

2

3

6

7

4

5

6

3

2

6

1

Keys

1 Stainless steel FGR pipe, insulated

2 Burner

3 Boiler

4 Bellow unit (a counter-flange supplied

loose is to be welded to the FGR duct)

5 FGR butterfly valve

6 Siphon and condensate drainage

7 Stack

8

PT1000

Flue gas temperature probe

Summary of Contents for H365X

Page 46: ......

Page 47: ......

Page 49: ...Siemens LMV5x Service Manual M12920CC rev 2 1 08 2017...

Page 56: ...8...

Page 60: ...12 2 2 LMV5x program structure...

Page 87: ...39...

Page 94: ......

Page 95: ......

Page 96: ...Note Specifications and data subject to change Errors and omissions excepted...

Page 98: ...Annex1 Example for motor cable...

Page 99: ......

Page 100: ...Annex 2 Example for sensor cable...

Page 101: ......

Page 102: ......

Page 106: ......