C.I.B. UNIGAS - M03957CI

38

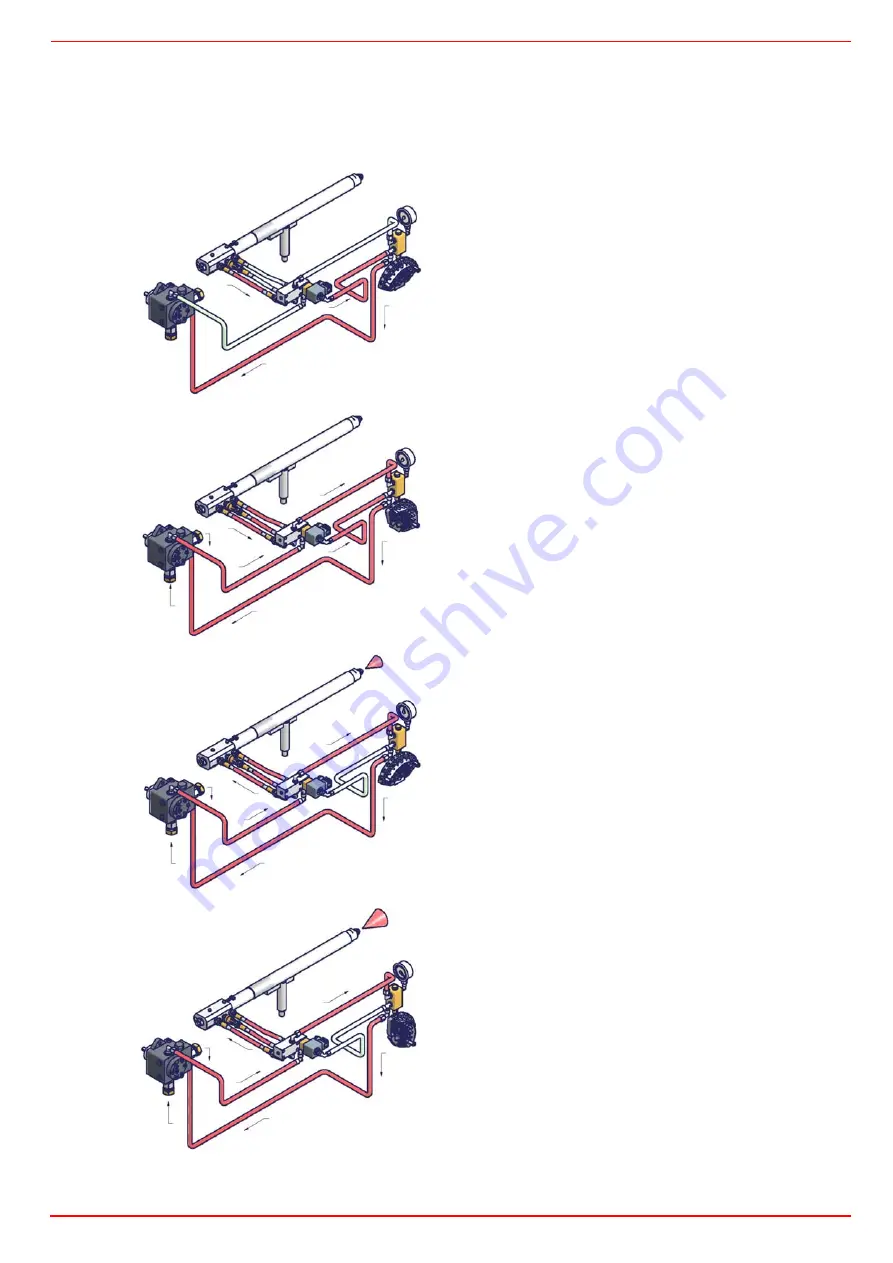

Oil circuit

The fuel is pushed into the pump 1 to the nozzle 3 at the delivery pressure set by the pressure governor. The solenoid valve 2 stops the

fuel immission into the combustion chamber. The fuel flow rate that is not burnt goes back to the tank through the return circuit. The

spill-back nozzle is feeded at constant pressure, while the return line pressure is adjusted by means of the pressure governor controlled

by an actuator coupled to an adjusting cam. The fuel amount to be burnt is adjusted by means of the burner actuator according to the

adjustments set (see prevoius paragraph).

Fig. 42 - Stand-by

Fig. 43 - Prepurge

Fig. 44 - Low flame

Fig. 45 - High flame

Key

1

Oil pump

2

Oil solenoid valve

3

Nozzle

4

Adjusting cam

5

Pressure gauge

6

Pressure governor

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

1

2

3

4

5

6

Summary of Contents for HP60

Page 9: ...C I B UNIGAS M03957CI 9 Overall dimensions mm Boiler recommended drilling template ...

Page 49: ...C I B UNIGAS M03957CI 49 ...

Page 51: ...C I B UNIGAS M03957CI 51 WIRING DIAGRAM Cod 05 680 Progressive burners ...

Page 52: ...C I B UNIGAS M03957CI 52 WIRING DIAGRAM Cod 05 681 Fully modulating burners ...

Page 54: ......

Page 55: ......

Page 56: ......