APPENDIX - COMPONENTS CHARACTERISTICS

22

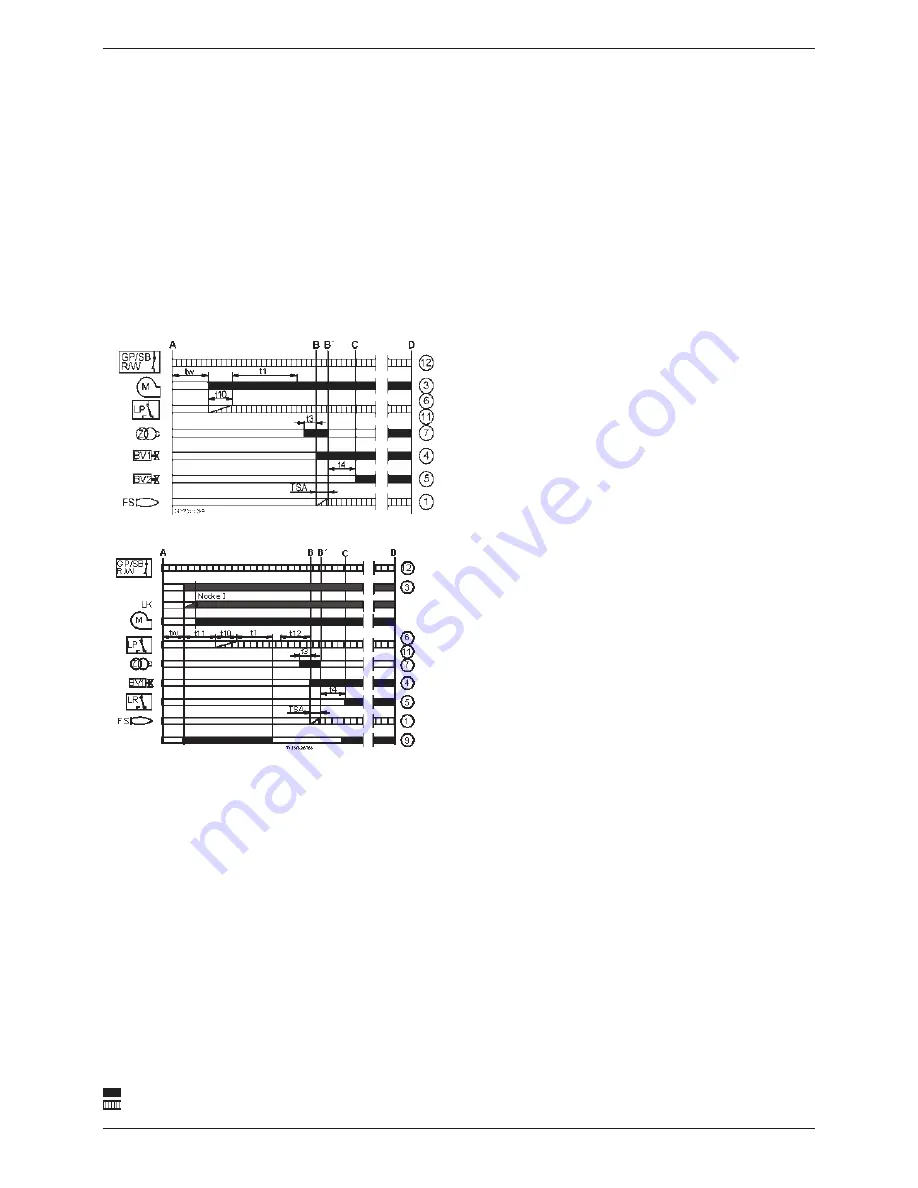

LANDIS LGB 21/22.. FLAME CONTROLLER

Function

The programme run is shown in the diagrams. The required and per-

missible input signals for the control part and flame supervision part

are pictured as a hatching correspondingly in the function diagrams. If

these input signals are missing, the controller interrupts the start-up

programme and initiates a lock-out at the place where the safety

regulations demand it.

The LGB types are fitted with under voltage protection, i.e. the load

relay AR is de-energized when the supply voltage falls below 160 V.

The burner control automatically attempts a new start-up when the

supply voltage again exceeds 160 V

A

Start-up command from the temperature or pressure

controller “R”

A-C

Start-up programme

C-D

Burner operation (heat production corresponding to the control

commands)

D

Controlled shut-down by “R”

LGB21

LGB22

Key for operation diagram

A - C Startup sequence

tw

Waiting time, 8s for LGB21, 9s for LGB22

t1

Prepurge time 30s

TSA Ignition safety time 3s

t3

Preignition time, 2s for LGB21, 3s for LGB22

t4

Interval «BV1-BV2» or «BV1-LR», 8s

t10

Specified time for air pressure signal, 5s for LGB21, 3s for

LGB22

t11

Programmed opening time for actuator «SA», max. 12s

t12

Programmed closing time for actuator «SA», max. 11s

BV

Fuel valves

FS

Flame presence signal

GP

Gas pressure switch

LP

Air pressure switch

LR

Load controller

M

Fan motor

R

Temperature or pressure controller

W

Safety thermostat or pressure switch

Z

Ignition transformer

1...12 Terminals of the burner flame controls on AGK11's socket

Command signal from flame control

Input signals

Conditions for starting up the burner:

z

The burner control must not be locked out.

z

The contacts of the gas pressure switch ”GP", the temperature or

pressure switch “W" and the controller “R", must be closed.

Start-up programme

A

Start command (switching on)

This command is triggered by control thermostat / pressure controller

«R». Terminal 12 receives voltage and the programming mechanism

starts running. On completion of waiting time «tw» with the LGB21...,

or after air damper «SA» has reached the nominal load position (on

completion of «t11») with the LGB22..., fan motor «M» will be started.

tw

Waiting time

During the waiting time, air pressure monitor «LP» and flame relay

«FR» are tested for correct contact positions.

t11

Programmed opening time for actuator «SA»

(Only with LGB22...) The air damper opens until the nominal load

position is reached. Only then will fan motor «M» be switched on.

t10

Specified time for air pressure signal

On completion of this period of time, the set air pressure must have

built up, or else lockout will occur.

t1

Prepurge time

Purging the combustion chamber and the secondary heating surfa-

ces: required with low-fire air volumes when using the LGB21... and

with nominal load air volumes when using the LGB22.... The dia-

grams show the so-called prepurge time «t1» during which air pres-

sure monitor «LP» must indicate that the required air pressure is

available. The effective prepurge time «t1» comprises interval end

«tw» through «t3».

t12 Programmed closing time for actuator «SA»

(Only with LGB22...)During «t12», the air damper travels to the low-

fire position.

t3 Preignition time

During «t3» and up to the end of «TSA», flame relay «FR» is forced to

close. On completion of «t3», the release of fuel is triggered at termi-

nal 4.

TSA Ignition safety time

On completion of «TSA», a flame signal must be present at terminal

1. That flame signal must be continuously available until shutdown

occurs, or else flame relay «FR» will be deenergized, resulting in

lockout.

t4 Interval

LGB21...: time to the release of the second fuel valve «BV2»

LGB22...: on completion of «t4», the heat source is controlled depen-

ding on the load (release of load controller «LR»)

B - B' Interval for flame establishment

C

Burner operation position

C - D Burner operation (heat production)

Operation of the burner at the maximum strenght or, with a flame con-

troller for the load.

D

Controlled by "R" shutdown

The burner stops, waiting for the next ignition.