25

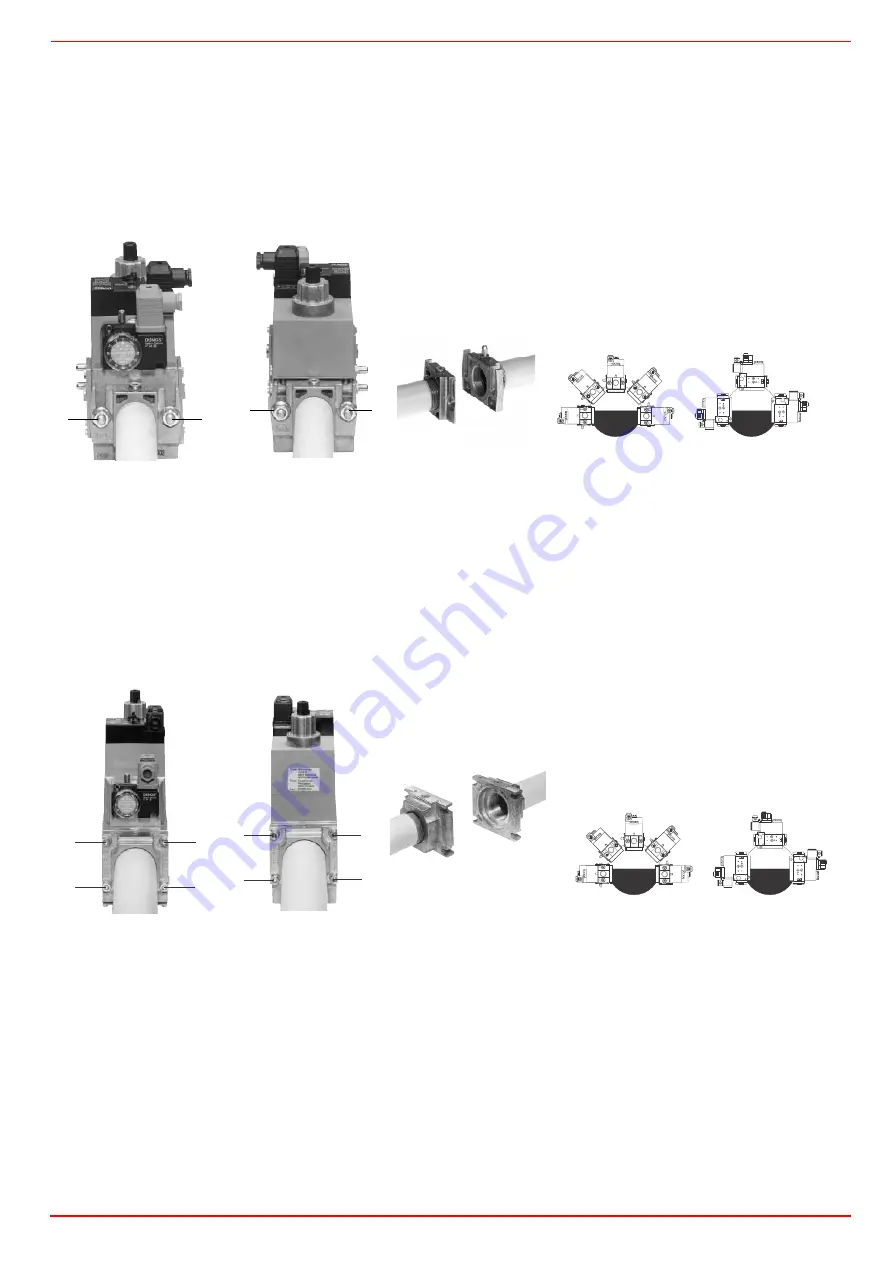

MULTIBLOC DUNGS MB-DLE 405..412

Mounting

1. Mount flange onto tube lines: use appropriate sealing agent (see Fig. 30);

2. insert MB-DLE: note position of O rings (see Fig. 30);

3. tighten screws A, B, C and D (Fig. 28 - Fig. 29), accordind to the mounting positions (Fig. 31);

4. after installation, perform leakage and functional test;

5. disassembly in reverse order.

MULTIBLOC DUNGS MB-DLE 415..420

Mounting

1. Loosen screws A and B

do not

unscrew (Fig. 28 - Fig. 29).

2. unscrew screws C and D (Fig. 28 - Fig. 29).

3. Remove MultiBloc between the threaded flanges (Fig. 29).

4. After mounting, perform leakage and functional tests.

Once the train is installed, connect the gas valves group plug.

Fig. 24

Fig. 25

Fig. 26

Fig. 27

Fig. 28

Fig. 29

Fig. 30

Fig. 31

A

B

D

C

MOUNTING POSITIONS

A

B

C

D

C

B

D

A

MOUNTING POSITIONS