PART IV: MAINTENANCE

43

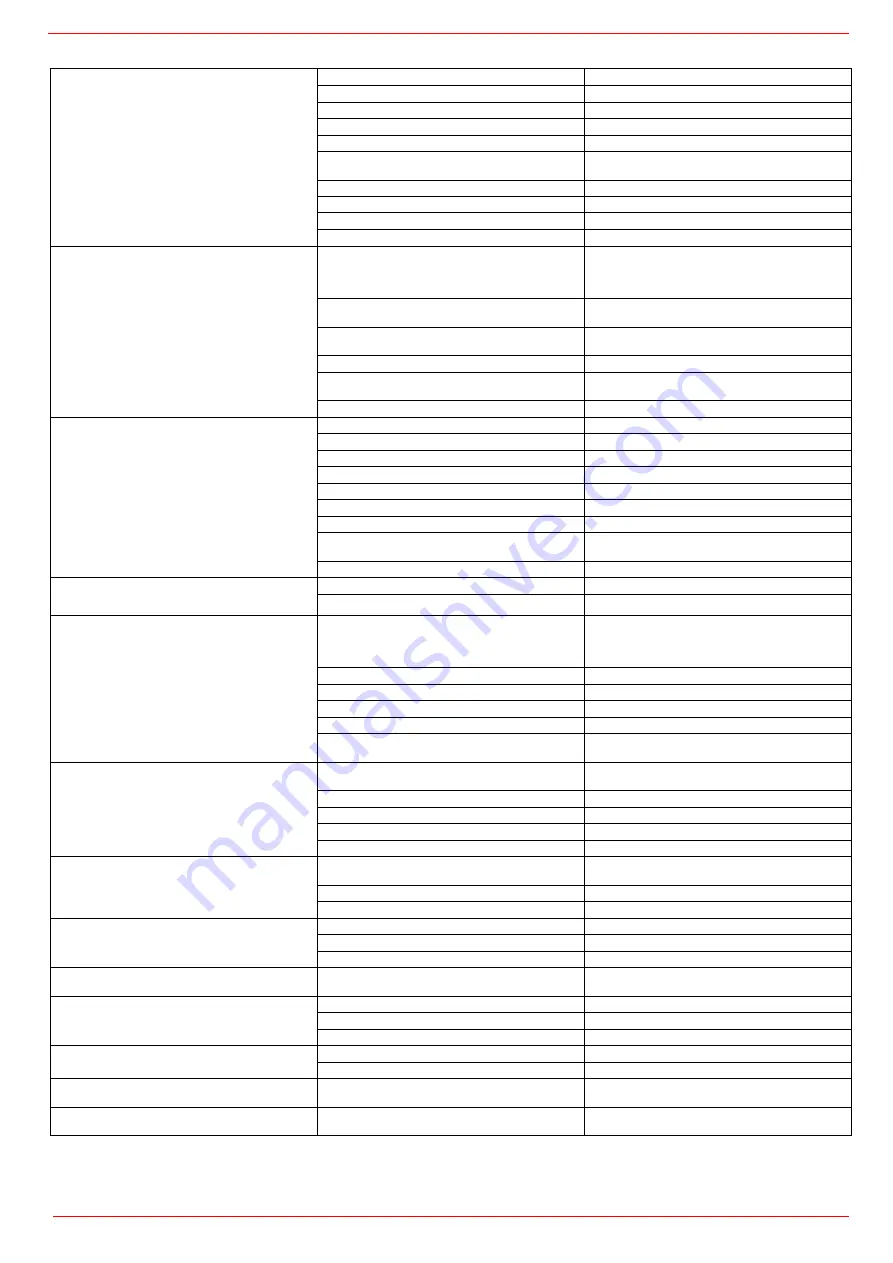

TROUBLESHOOTNG GUIDE Gas operation

TROUBLESHOOTNG GUIDE Light oil operation

BURNER DOESN'T LIGHT

* No electric power supply

* Restore power supply

* Main switch open

* Close switch

* Thermostats open

* Check set points and thermostat connections

* Bad thermostat set point or broken thermostat

* Reset or replace the thermostat

* No gas pressure

* Restore gas pressure

* Safety devices (manually operated safety thermostat,

pressure switches and so on) open

* Restore safety devices; wait till boiler reaches operating

temperature then check safety device functionality.

* Broken fuses

* Replace fuses. Check current absorption

* Fan thermal contacts open (three phases motors only) * Reset contacts and check current absorption

* Burner control lock out

* Reset and check its functionality

* Burner control damaged

* Replace burner control

GAS LEAKAGE: BURNER LOCKS OUT

(NO FLAME)

* Gas flow is too low

* Increase the gas flow

* Check gas filter cleanness

* Check butterfly valve opening when burner is starting

(only Hi-Low flame and progressive)

* Ignition electrodes discharge to ground because dirty or

broken

* Clean or replace electrodes

* Bad electrodes setting

* Check electrodes position referring to instruction

manual

* Electrical ignition cables damaged

* Replace cables

* Bad position of cables in the ignition transformer or into

the electrodes

* Improve the installation

* Ignition transformer damaged

* Replace the transformer

BURNER LOCKS OUT WITH FLAME PRESENCE

* Wrong setting of flame detector

* Adjust flame detector

* Flame detector damaged

* Replace flame detector

* Bad cables of flame detector

* Check cables

* Burner control damaged

* Replace burner control

* Phase and neutral inverted

* Adjust connections

* Ground missing or damaged

* Check ground continuity

* Voltage on neutral

* Take off tension on neutral

* Too small flame (due to not much gas)

* Adjust gas flow

* Check gas filter cleanness

* Too much combustion air

* Adjust air flow rate

only FOR LME22: BURNER CONTINUES TO PER-

FORM ALL ITS FEATURES WITHOUT IGNITING

THE BURNER

* Air pressure switch damaged or bad links

* Check air pressure switch functions and links

* Burner control damaged

* Replace burner control

BURNER LOCKS OUT WITHOUT ANY GAS FLOW

* Gas valves don’t open

* Check voltage on valves; if necessary replace valve or

the burner control

* Check if the gas pressure is so high that the valve

cannot open

* Gas valves completely closed

* Open valves

* Pressure governor too closed

* Adjust the pressure governor

* Butterfly valve closed

* Open the butterfly valve

* Maximum pressure switch open.

* Check connection and functionality

* Air pressure switch doesn’t close the NO contact

* Check connections

* Check pressure switch functionality

THE BURNER IS BLOCKED AND THE EQUIPMENT

PROVIDES A LOCK CODE "CAUSE AIR PRESSURE

SWITCH FAULT"

* Air pressure switch damaged (it keeps the stand-by

position or badly set)

* Check air pressure switch functionality

* Reset air pressure switch

* Air pressure switch connections wrong

* Check connections

* Air fan damaged

* Replace motor

* No power supply

* Reset power supply

* Air damper too closed

* Adjust air damper position

BURNER LOCKS OUT DURING NORMAL RUNNING

* Flame detector circuit interrupted

* Check wiring

* Check photocell

* Burner control damaged

* Replace burner control

* Maximum gas pressure switch damaged or badly set

* Reset pressure switch or replace it

THE BURNER STARTS AND AFTER A WHILE IT

REPEATS THE STARTING CYCLE.

* Gas pressure switch badly set

* Reset the pressure switch

* Gas filter dirty

* Clean gas filter

* Gas governor too low or damaged

* Reset or replace the governor

BURNER STANDS WHILE RUNNING WITHOUT ANY

SWITCHING OF THERMOSTATS

* Thermal contacts of fan motor open

* Reset contacts and check values

* Check current absorption

FAN MOTOR DOESN'T START

* Internal motor wiring broken

* Replace wiring or complete motor

* Fan motor starter broken

* Replace starter

* Fuses broken (three phases only)

* Replace fuses and check current absorption

BURNER DOESN'T SWITCH TO HIGH FLAME

* Hi-low flame thermostat badly set or damaged

* Reset or replace thermostat

* Servomotor cam badly set

* Reset servomotor cam

mechanical only

: SOMETIMES THE SERVOMOTOR

RUNS IN THE WRONG WAY

* Servomotor capacitor damaged

* Replace capacitor

PHASE-TO-PHASE SUPPLY OR PRESENCE OF

VOLTAGE ON NEUTRAL*

* Lights up and freezes

* In such cases, insert an RC circuit (our code 2531003).

Summary of Contents for K890A

Page 45: ......

Page 46: ......

Page 47: ......

Page 49: ...Service manual AZL2x LMV2x 3x Burner Management System M12916CD Rev 3 4 03 2023 ...

Page 56: ...8 Parameters level heating engineer ...

Page 98: ...50 ERROR CODE TABLE ...

Page 99: ...51 ...

Page 100: ...52 ...

Page 101: ...53 ...

Page 102: ...54 ...

Page 103: ...55 ...

Page 104: ...56 ...

Page 105: ...57 ...

Page 106: ...58 ...

Page 107: ...59 ...

Page 108: ...60 ...

Page 109: ...61 ...

Page 110: ...62 ...

Page 111: ...63 ...

Page 112: ...64 ...

Page 117: ......

Page 118: ......

Page 119: ......

Page 121: ...WB1 QF B QF A ...

Page 122: ......

Page 123: ......

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ...QF A QF B ...

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......