PART II: INSTALLATION

15

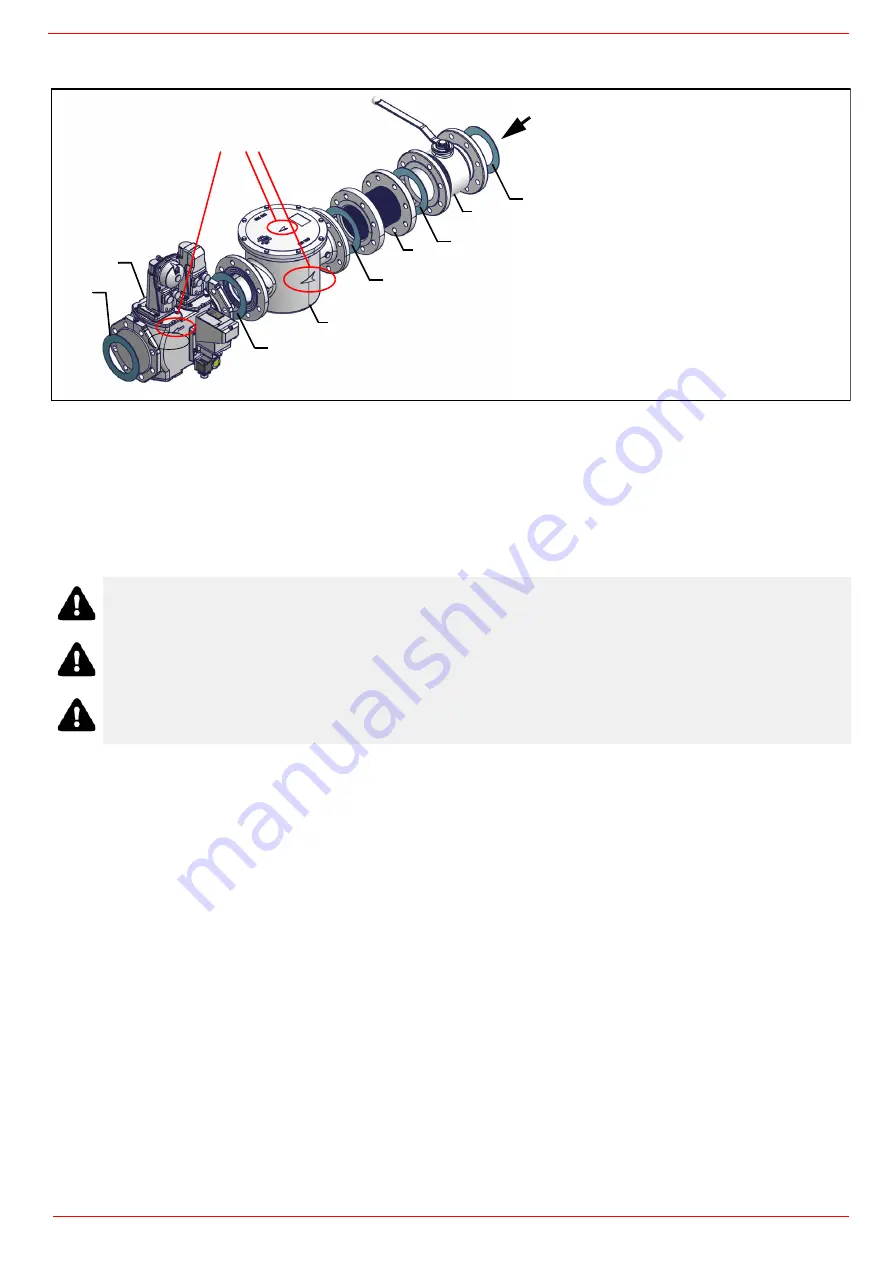

GAS TRAIN CONNECTIONS

The diagrams show the components of the gas train included in the delivery and which must be

fitted by the installer.The diagrams are in compliance with the current laws.

Procedure to install the double gas valve unit:

two (2) gas flanges are required; they may be threaded or flanged depending on size

first step: install the flanges to prevent entry of foreign bodies in the gas line

on the gas pipe, clean the already assembled parts and then install the valve unit

check gas flow direction: it must follow the arrow on the valve body

VGD20: make sure the O-rings are correctly positioned between the flanges and the valve

VGD40 and MBE: make sure the gaskets are correctly positioned between the flange

fasten all the components with screws, according to the following diagrams

make sure bolts on the flanges are properly tightened

To mount the gas train, proceed as follows:

NOTE:

the bellows unit, the manual cutoff valve and the gaskets are not part of the standard supply

WARNING: before executing the connections to the gas pipe network, be sure that the manual cutoff valves are

closed.

ATTENTION: it is recommended to mount filter and gas valves to avoid that extraneous material drops inside the

valves, during maintenance and cleaning operation of the filters (both the filters outside the valves group and the

ones built-in the gas valves).

ATTENTION: once the gas train is mounted, the gas proving test must be performed, according to the procedure

set by laws in force.

1

-

In case of threaded joints: use proper seals according to the gas used- in case of flanged joints: place a gasket between the ele-

ments

2

Fasten all the items by means of screws, according to the diagrams showed, observing the mounting direction for each item

Keys

1A..1E Gasket

2 Gas filter

3 Gas valves group

4 Bellows unit

5 Manual valve

”direction” arrows for installation

gas supply network

Note: the figure is indicative only

1A

1B

1C

1D

1E

2

4

5

3

Summary of Contents for K990A

Page 41: ...PART IV MAINTENANCE 41...

Page 42: ......

Page 43: ......

Page 45: ...Siemens LMV5x Service Manual M12920CC rev 2 1 08 2017...

Page 52: ...8...

Page 56: ...12 2 2 LMV5x program structure...

Page 83: ...39...

Page 90: ......

Page 91: ......

Page 92: ...Note Specifications and data subject to change Errors and omissions excepted...

Page 94: ...Annex1 Example for motor cable...

Page 95: ......

Page 96: ...Annex 2 Example for sensor cable...

Page 97: ......

Page 98: ......

Page 102: ......