PART IV: MAINTENANCE

50

At least once a year carry out the maintenance operations listed below. In the case of seasonal servicing, it is recommended to carry

out the maintenance at the end of each heating season; in the case of continuous operation the maintenance is carried out every 6

months.

ROUTINE MAINTENANCE

Clean and examine the gas filter and replace it if necessary.

Clean and examine the oil filter cartridge and replace it if necessary.

Examine the flexible hoses and check for possible leaks.

Check and clean if necessary the oil heaters and the tank, according to the fuel type and its use; remove the heaters flange fixing

nuts and remove the heaters from the tank: clean by using steam or solvents and not metallic things.

Remove and clean the combustion head.

Examine and clean the ignition electrode, adjust and replace if necessary.

Examine and clean the detection probe, adjust and replace if necessary.

Examine the detection current.

Remove and clean the heavy oil nozzle

(Important: use solvents for cleaning, not metallic tools)

and at the end of the mainte-

nance procedures, after replacing the burner, turn it on and check the shape of the flame; if in doubt replace the nozzle. Where the

burner is used intensively it is recommended to replace the nozzle as a preventive measure, at the begin of the operating season.

Clean and grease joints and rotating parts.

IMPORTANT:Remove the combustion head before checking the ignition electrode.

Remove and clean the compressed air regulator

Remove and clean the oil regulator (if provided)

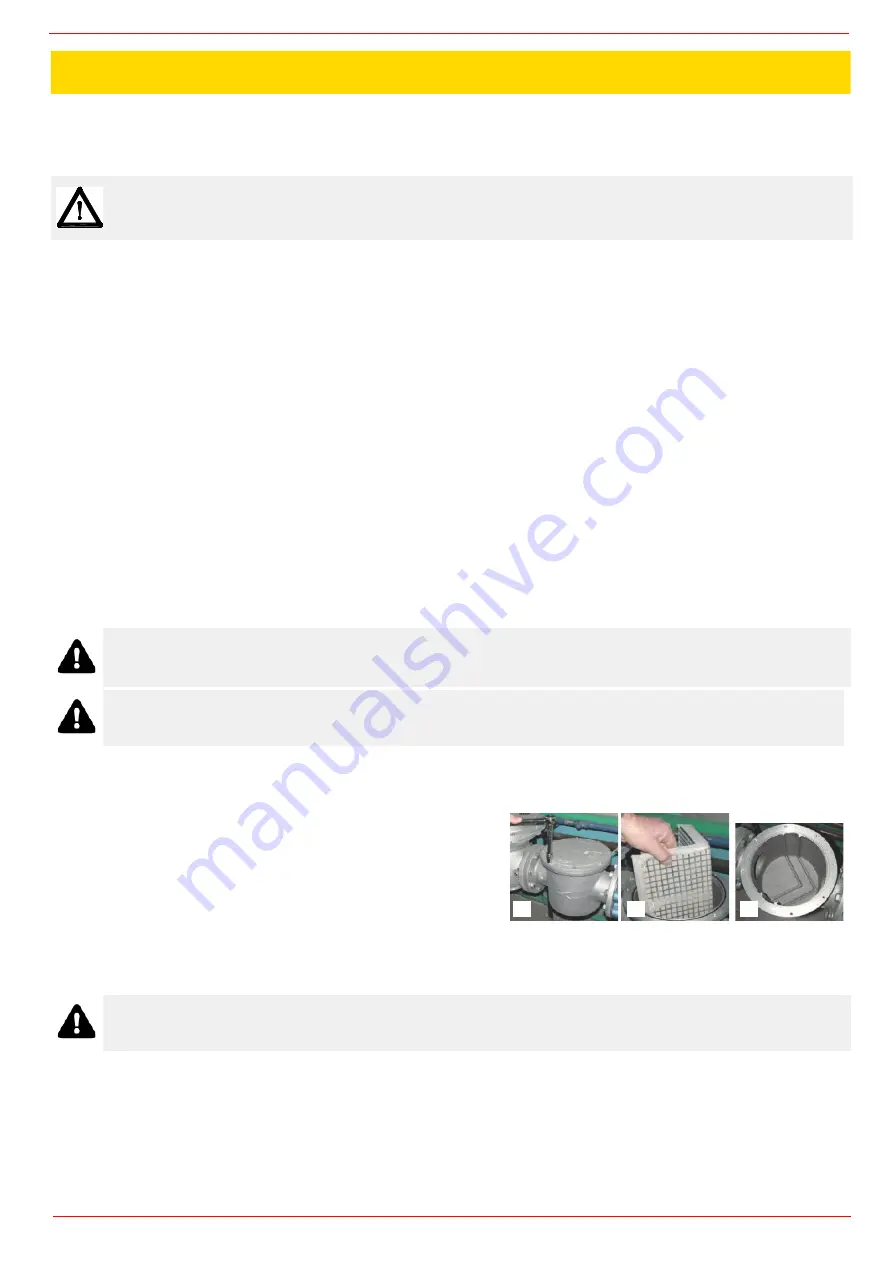

Gas filter maintenance

WARNING: ALL OPERATIONS ON THE BURNER MUST BE CARRIED OUT WITH THE MAINS DISCONNECTED AND

THE FUEL MANAUL CUTOFF VALVES CLOSED!

ATTENTION: READ CAREFULLY THE “WARNINGS” CHAPTER AT THE BEGINNIG OF THIS MANUAL.

CAUTION: avoid the contact of steam, solvent and other liquids with the electric terminals of the resistor.

On flanged heaters, replace the seal gasket before refitting it.

Periodic inspections must be carried out to determine the frequency of cleaning.

ATTENTIONwhen servicing, if it was necessary to disassemble the gas train parts, remember to execute the gas

proving test, once the gas train is reassembled, according to the procedure imposed by the law in force.

WARNING: Before opening the filter, close the manual cutoff valve downstream the filter and bleed the gas; check

that inside the filter there is no pressurised gas.

PART IV: MAINTENANCE

C

B

A

To clean or remove the filter, proceed as follows:

1 remove the cap unscrewing the fixing screws (A);

2 remove the filtering cartridge (B), clean it using water and soap, blow it

with compressed air(or replace it, if necessary)

3 replace the cartridge in its proper position taking care to place it

inbetween the guides as not to hamper the cap replacement;

4 be sure to replace the “O” ring into its place (C) and replace the cover

fastening by the proper screws (A).

Summary of Contents for KP91

Page 49: ...PART III OPERATION 49 Pressure gauge port RP Pressure gauge port V2 SV2 PG...

Page 61: ......

Page 62: ......

Page 63: ......