PART I: SPECIFICATIONS

7

Heavy oil net calorific value (Hi): 40.4MJ/kg (average value).

(*) NOTE ON THE WORKING SERVICE: the control box automatically stops after 24h of continuous working. The control box

immediately starts up, automatically.

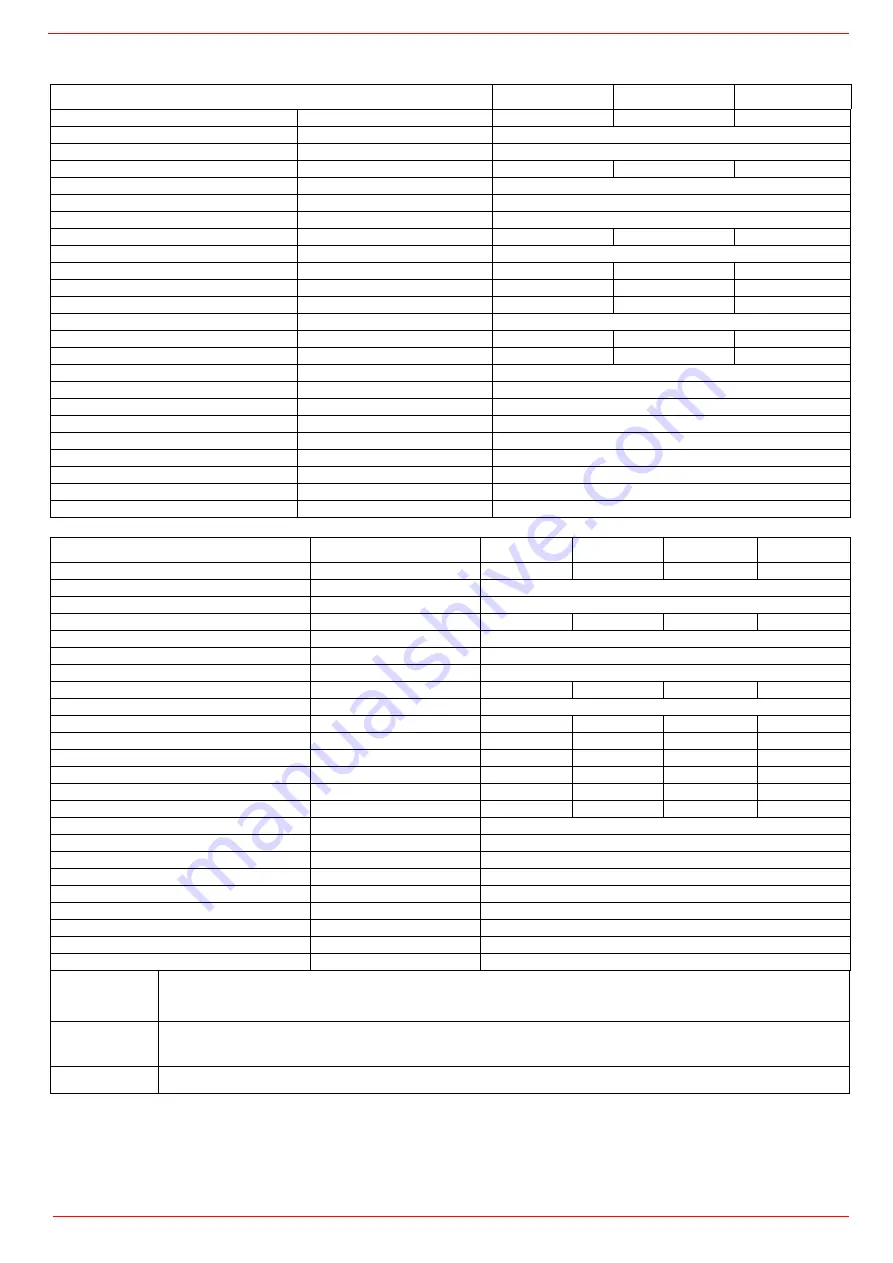

BURNERS

KP91 L-

KP92 L-

KP93 L-

Output

min. - max. kW

480 - 2670

480-3050

550 - 4100

Fuel

LD - L LPG - D Heavy oil, viscosity <= 400cSt (50° E) @ 50° C

Category

(see next paragraph)

Gas rate

- LPG

min. - max. (Stm

3

/h)

17,9 - 100

17,9 - 114

21 - 153

Gas pressure

min. - max. mbar

(Note2)

Viscosity

See “Burner model identification” table

Oil train inlet pressure

max. bar

4

Heavy oil rate

min. - max. kg/h

42 - 233

43 - 272

49 - 365

Power supply

400V 3N ~ 50Hz

Total power consumption (Heavy oil)

kW

23,6

25,1

33,1

Total power consumption (Petroleum)

kW

11,6

13,1

17,1

Fan motor

kW

4

5.5

7.5

Pump motor

kW

1.1

Pre-heater resistors (heavy oil)

kW

18

18

24

Pre-heater resistors (Petroleum)

kW

6

6

8

Protection

IP40

Operation

Progressive - Fully modulating

Gas Train 50

Valves size

/

Gas connection

50 / Rp 2”

Gas Train 65

Valves size

/

Gas connection

65 / 65

Gas Train 80

Valves size

/

Gas connection

80 / 80

Gas Train 100

Valves size

/

Gas connection

100 / 100

Operating temperature

°C

-10 ÷ +50

Storage Temperature

°C

-20 ÷ +60

Working service*

Intermittent

BURNERS

KR512 L-

KR515 L-

KR520 L-

KR525 L-

Output

min. - max. kW

600 - 4500

770 - 5200

1000 - 6400

2000 - 8000

Fuel

LD - L LPG - D Heavy oil, viscosity <= 400cSt (50° E) @ 50° C

Category

(see next paragraph)

Gas rate

- LPG

min. - max. (Stm

3

/h)

22 - 168

29 - 194

37 - 239

75 - 299

Gas pressure

min. - max. mbar

(Note2)

Viscosity

See “Burner model identification” table

Oil train inlet pressure

max. bar

4

Heavy oil rate

min. - max. kg/h

53 - 401

69 - 463

89 - 570

178 - 713

Power supply

400V 3N ~ 50Hz

Total power consumption (Heavy oil)

kW

35,2

43

59,7

69,2

Total power consumption (Petroleum)

kW

19,2

23

31,7

37,2

Fan motor

kW

9,2

11

15

18,5

Pump motor

kW

1,5

1,5

2,2

2,2

Pre-heater resistors (heavy oil)

kW

24

30

42

48

Pre-heater resistors (Petroleum)

kW

8

10

14

16

Protection

IP40

Operation

Progressive - Fully modulating

Gas Train 50

Valves size

/

Gas connection

50 / Rp 2”

Gas Train 65

Valves size

/

Gas connection

65 / 65

Gas Train 80

Valves size

/

Gas connection

80 / 80

Gas Train 100

Valves size

/

Gas connection

100 / 100

Operating temperature

°C

-10 ÷ +50

Storage Temperature

°C

-20 ÷ +60

Working service*

Intermittent

Note1:

All gas flow rates are referred to Stm

3

/h (1.013 mbar absolute pressure, 15° C temperature) and are valid for G20 gas

(net calorific value H

i

= 34.02 MJ / Stm

3

);

Note2:

Maximum gas pressure = 500mbar (with

Siemens VGD or Dungs MultiBloc MBE)

Minimum gas pressure = see gas curves.

Note3:

Burners are suitable only for indoor operation with a maximum relative humidity of 80 %

Summary of Contents for KP91

Page 49: ...PART III OPERATION 49 Pressure gauge port RP Pressure gauge port V2 SV2 PG...

Page 61: ......

Page 62: ......

Page 63: ......