C.I.B. UNIGAS - M039207CB

23

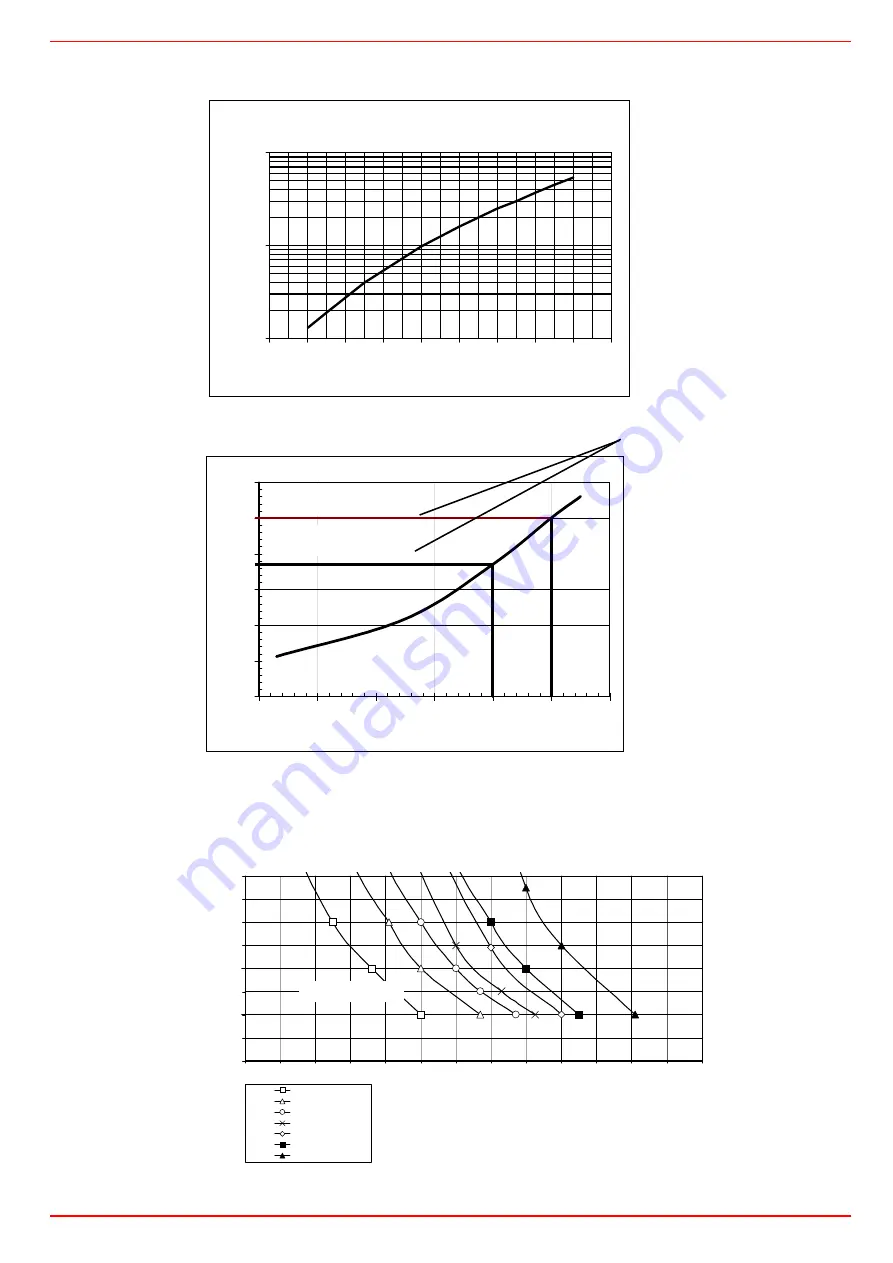

Minimum feeding temperature vs. oil viscosity

The use of heavy oil forces to feed the burner to a pressure strictly related to the oil temperature. This avoids damage to the pump cau-

sed by gassification.

OIL TEMPERATURE FOR PUMP FEEDING

1

10

100

0

10

20

30

40

50

60

70

80

90

TEMPERATURE (°C)

VISC

OSITY (°E a 50°C

)

Fig. 13

PUMP FEEDING PRESSURE

Max. for E ..1069

pimps

Max. for T and

TA pumps

0

1

2

3

4

5

6

40

60

80

100

120

140

160

TEMPERATURE (°C)

PRESSURE (bar)

Pumps operating range

Fig. 14

VISCOSITY vs. TEMPERATURE DIAGRAM

BEST VISCOSITY RANGE FOR A

PROPER ATOMIZATION

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

50

60

70

80

90

100

110

120

130

140

150

160

170

180

TEMPERATURE (°C)

VISCOSITY (°E)

3°E AT 50°C

5°E AT 50°C

7°E AT 50°C

12°E AT 50°C

15°E AT 50°C

20°E AT 50°C

50°E AT 50°C

Fig. 15

Summary of Contents for KTP1030

Page 25: ...C I B UNIGAS M039207CB 25 Fig 17 Hydraulic diagram 3ID0014 Two or more burners configuration...

Page 46: ...C I B UNIGAS M039207CB 46...

Page 47: ...C I B UNIGAS M039207CB 47...

Page 48: ...C I B UNIGAS M039207CB 48...

Page 49: ...C I B UNIGAS M039207CB 49...

Page 50: ...C I B UNIGAS M039207CB 50 Pumping Unit Electric Wiring Diagrams...

Page 51: ...C I B UNIGAS M039207CB 51...

Page 52: ...C I B UNIGAS M039207CB 52...

Page 55: ...C I B UNIGAS M039207CB 55...

Page 59: ......

Page 74: ......

Page 83: ......

Page 84: ......

Page 85: ...RWF50 2x RWF50 3x User manual M12922CB Rel 1 0 07 2012...

Page 100: ...16 Note Specifications and data subject to change Errors and omissions excepted...

Page 101: ...KM3 Modulator USER MANUAL M12927CA Rel 1 0 10 2020...

Page 102: ...M12927CA MOUNTING 2...

Page 118: ...1 RWF55 5X RWF55 6X User manual M12926CA Rel 0 1 10 2015...

Page 119: ...2 DEVICE INSTALLATION Fixing system Drilling dimensions...

Page 140: ......

Page 141: ...23 Note Specifications and data subject to change Errors and omissions excepted...