5

GENERAL FEATURES

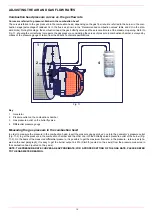

Burners of this series are provided with a removable cover made of ABS, a heat and crash proof plastic material. The design of the shi-

fitng flange assures an efficient tightness and room saving. All the mechanical components are mounted on a removable plate that

makes routine maintenance operation easier. The combustion head position can be easily adjusted by means of a indexed screw and

the peculiar air intake lower the noise levels.

Fig. 1

1

Blast tube-combustion head assembly

2

Burner flange

3

Control panel with startup switch

4

Air intake

5

Actuator

6

Air pressure switch

7

Cover

8

Printed board circuit

9

Control box

10 Gas valves group

The gas coming from the supply line, passes through the valves group provided with filter and stabiliser. This one forces the pressure in

the utilisation limits. In the double-stage, progressive and fully-modulating burners, the electric servocontrol (5) moves proportionally

the air damper: it uses an adjusting cam with variable shape. This one allows the optimisation of the gas flue values, as to get an effi-

cient combustion. The combustion head positioning determines the burner output. Fuel and comburent are routed into separated ways

as far as the zone of flame generation (combustion chamber). The air (comburent) and fuel (gas, gas oil, heavy oil) are forced into the

combustion chamber.

1

3

4

2

6

5

7

8

9

10