PART III: OPERATION

38

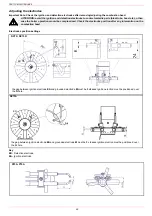

Gas valveversion with SKP2 (built-in pressure stabilizer)

To increase or decrease gas pressure, and therefore gas flow rate, remove the cap

T

and use

a screwdriver to adjust the regulating screw

VR

. Turn clockwise to increase the flow rate,

counterclockwise to reduce it.

Adjusting the gas valves group

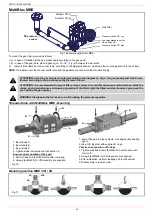

Multibloc MB-DLE

The multibloc unit is a compact unit consisting of two valves, gas pressure switch, pres-

sure stabilizer and gas filter.

The valve is adjusted by means of the

RP

regulator after slackening the locking screw

VB

by a number of turns. By unscrewing the regulator

RP

the valve opens, screwing the valve

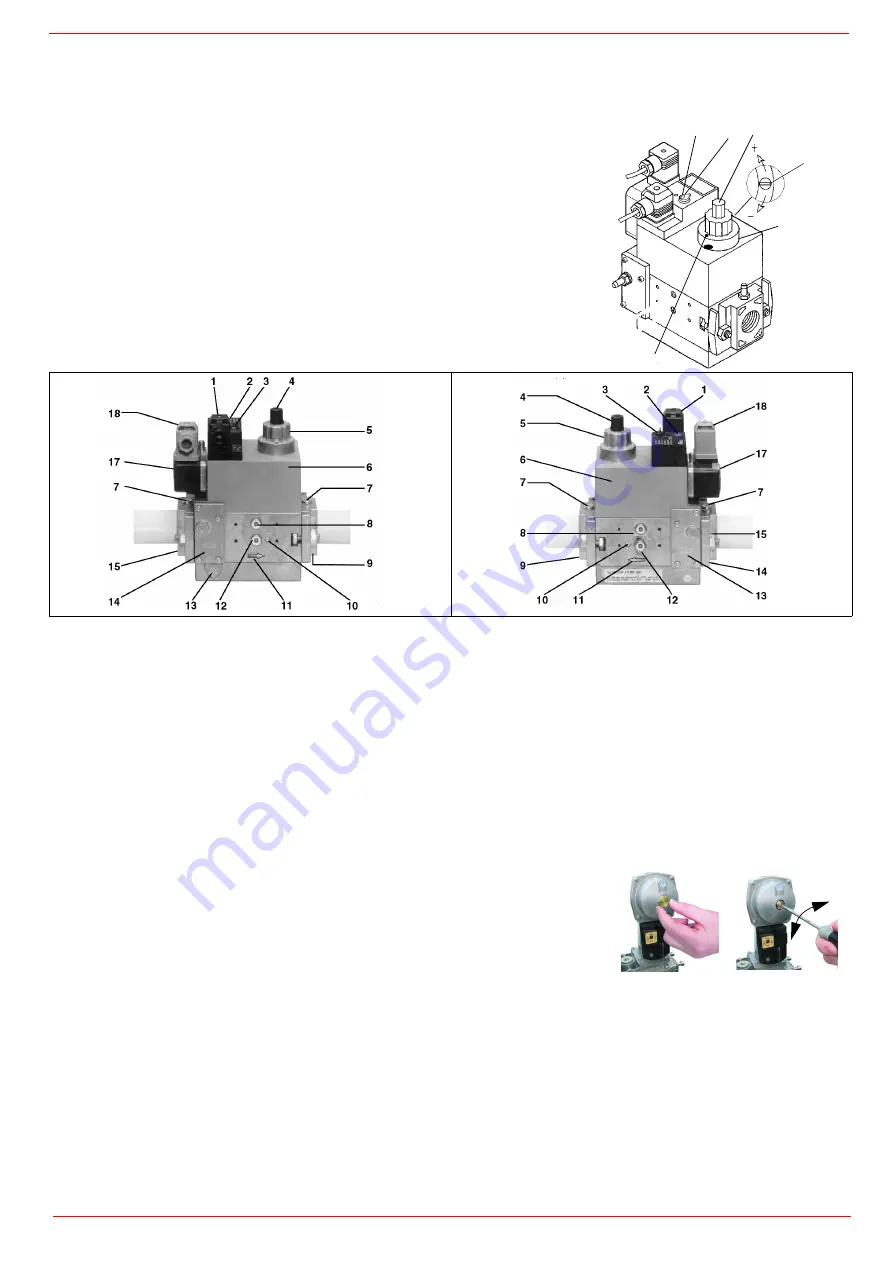

closes. To set the fast opening remove cover

T

, reverse it upside down and use it as a tool

to rotate screw

VR

. Clockwise rotation reduces start flow rate, anticlockwise rotation incre-

ases it.

Do not use a screwdriver on the screw

VR

!

The pressure stabilizer is adjusted by operating the screw

VS

located under the cover

C

.

By screwing down the pressure is increased and by unscrewing it is reduced.

Note: the screw

VSB

must be removed only in case of replacemente of the coil.

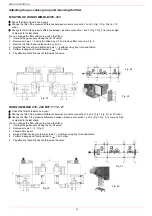

Fig. 22

Fig. 23

Key

1 Electrical connection for valves

2 Operation display (optional)

3 Pressure governor closing tap

4 Start setting cap

5 Hydraulic brake and rate regulator

6 Coil

7 Test point connection G 1/8

8 Test point connection G 1/8 downstream of valve 1, on both sides

9

Output flange

10 Test point connection M4 downstream of valve 2

11 Gas flow direction

12 Test connection G 1/8 downstream of valve 1, on both sides

13 Vent nozzle pressure regulator

14 Filter (below cover)

15 Input flange

17 Pressure switch

18 Pressure switch electric connection

C

VS T(VR)

RP

VB

VSB

Fig. 21

T

VR

+

-

Summary of Contents for P75R

Page 53: ...Service manual AZL2x LMV2x 3x Burner Management System M12916CD Rev 3 4 03 2023...

Page 60: ...8 Parameters level heating engineer...

Page 102: ...50 ERROR CODE TABLE...

Page 103: ...51...

Page 104: ...52...

Page 105: ...53...

Page 106: ...54...

Page 107: ...55...

Page 108: ...56...

Page 109: ...57...

Page 110: ...58...

Page 111: ...59...

Page 112: ...60...

Page 113: ...61...

Page 114: ...62...

Page 115: ...63...

Page 116: ...64...

Page 121: ......

Page 122: ......

Page 123: ......

Page 125: ...IG FU B...

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ......

Page 135: ......