C.I.B. UNIGAS

- M039241CB

8

INSTALLING THE BURNER

Packing

Burners are despatched in wooden crates whose dimensions are:

1520 mm x 1170 mm x 1130 mm(L x P x H)

:

Packing cases of this kind are affected by humidity and are not suitable for stacking. The fol-

lowing are placed in each packing case:

burner;

gasket to be inserted between the burner and the boiler;

oil flexible hoses;

oil filter;

envelope containing this manual.

To get rid of the burner’s packing, follow the procedures laid down by current laws on disposal of materials.

Handling the burner

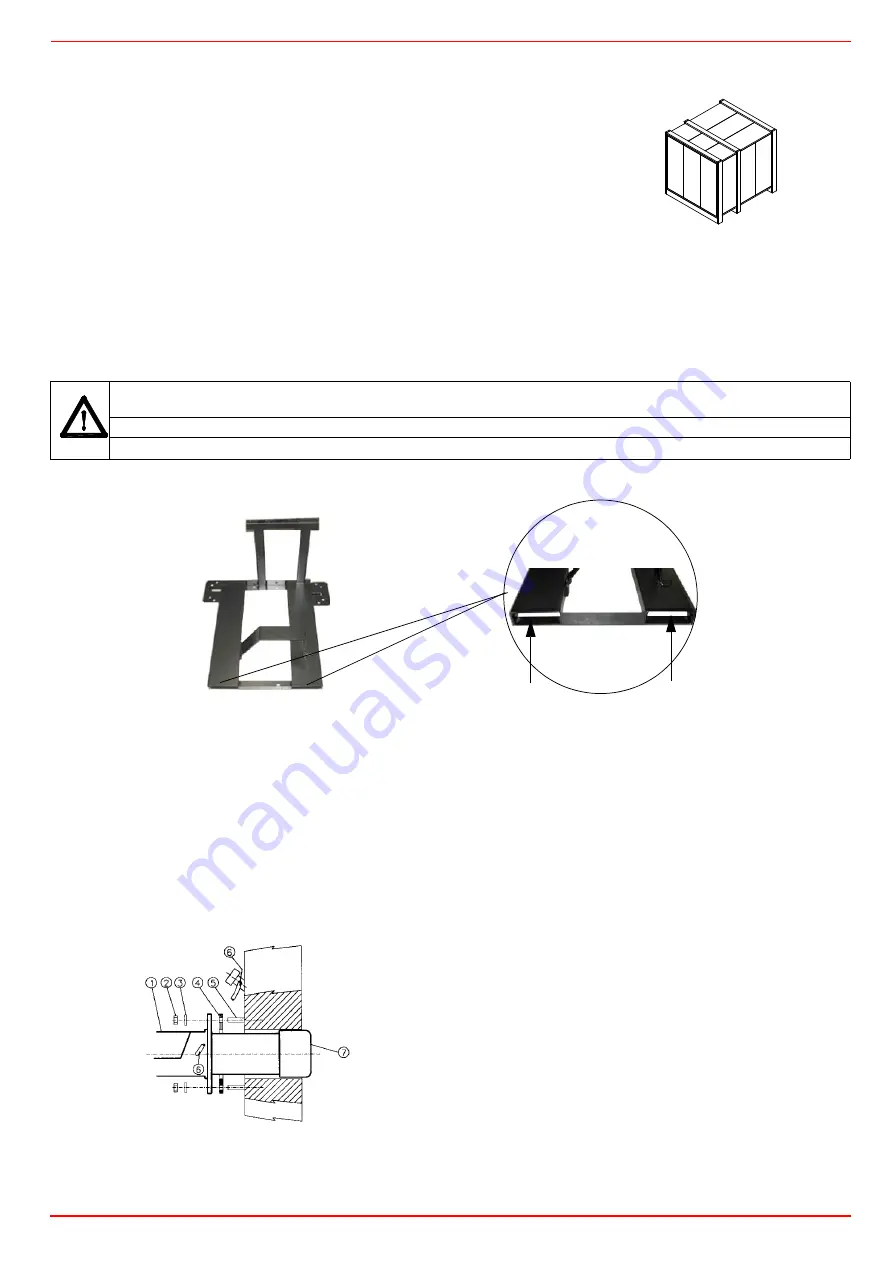

The burner is mounted on a stirrup provided for handling the burner by means of a fork lift truck: the forks must be inserted into the A

anb B ways. Remove the stirrup only once the burner is installed to the boiler.

Fitting the burner to the boiler

To install the burner into the boiler, proceed as follows:

1

make a hole on the closing door of the combustion chamber as described on paragraph “Overall dimensions”)

2

place the burner to the boiler: lift it up and handle it according to the procedure described on paragraph “Handling the burner”;

3

place the 4 stud bolts (5) on boiler’s door, according to the burner’s drilling template described on paragraph “Overall dimensions”;

4

fasten the 4 stud bolts;

5

place the gasket on the burner flange;

6

install the burner into the boiler;

7

fix the burner to the stud bolts, by means of the fixing nuts, according to the next picture.

8

After fitting the burner to the boiler, ensure that the gap between the blast tube and the refractory lining is sealed with appropriate

insulating material (ceramic fibre cord or refractory cement).

The burner is designed to work positioned according to the picture below. Set the upper side of the burner flange in a horizontal posi-

tion, in order to find the correct inclination of the pre-heating tank. For different installations, please contact the Technical Department.

ATTENTION! The lhandling operations must be carried out by specialised and trained personnel. If these opera-

tions are not carried out correctly, the residual risk for the burner to overturn and fall down still persists.

To move the burner, use means suitable to support its weight (see paragraph “Technical specifications”).

The unpacked burner must be lifted and moved only by means of a fork lift truck.

H

P

L

A

B

Keys

1

Burner

2

Fixing nut

3

Washer

4

Sealing gasket

5

Stud bolt

7

Blast tube

Summary of Contents for PBY70

Page 7: ...C I B UNIGAS M039241CB 7 Overall dimensions mm boiler recommended drilling template ...

Page 16: ...C I B UNIGAS M039241CB 16 HYDRAULIC DIAGRAMS Fig 8 Hydraulic diagram 3ID0024 ...

Page 18: ...C I B UNIGAS M039241CB 18 Fig 9 Hydraulic diagram 3I2D 01 ...

Page 37: ...C I B UNIGAS M039241CB 37 ...

Page 42: ......

Page 43: ......