C.I.B. UNIGAS

- M039144CD

24

9

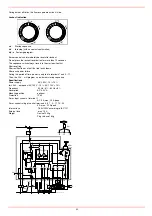

the nozzle supply pressureis already factory-set and must not be changed. Only if necessary, adjust the supply pressure as fol-

lows (see related paragraph);insert a pressure gauge into the port shown on Fig. 20 and act on on the pump adjusting screw

VR

(see Fig. 19 and page 15) as to get the nozzle pressure at 25bar (see page 17).

10 in order to get the maximum oil flow rate, adjust the pressure (reading its value on the

PG

pressure gauge): checking always the combu-

stion parameters, the adjustment is to be performed by means of the

SV

adjusting cam screw (see picture) when the cam has reached

the high flame position.

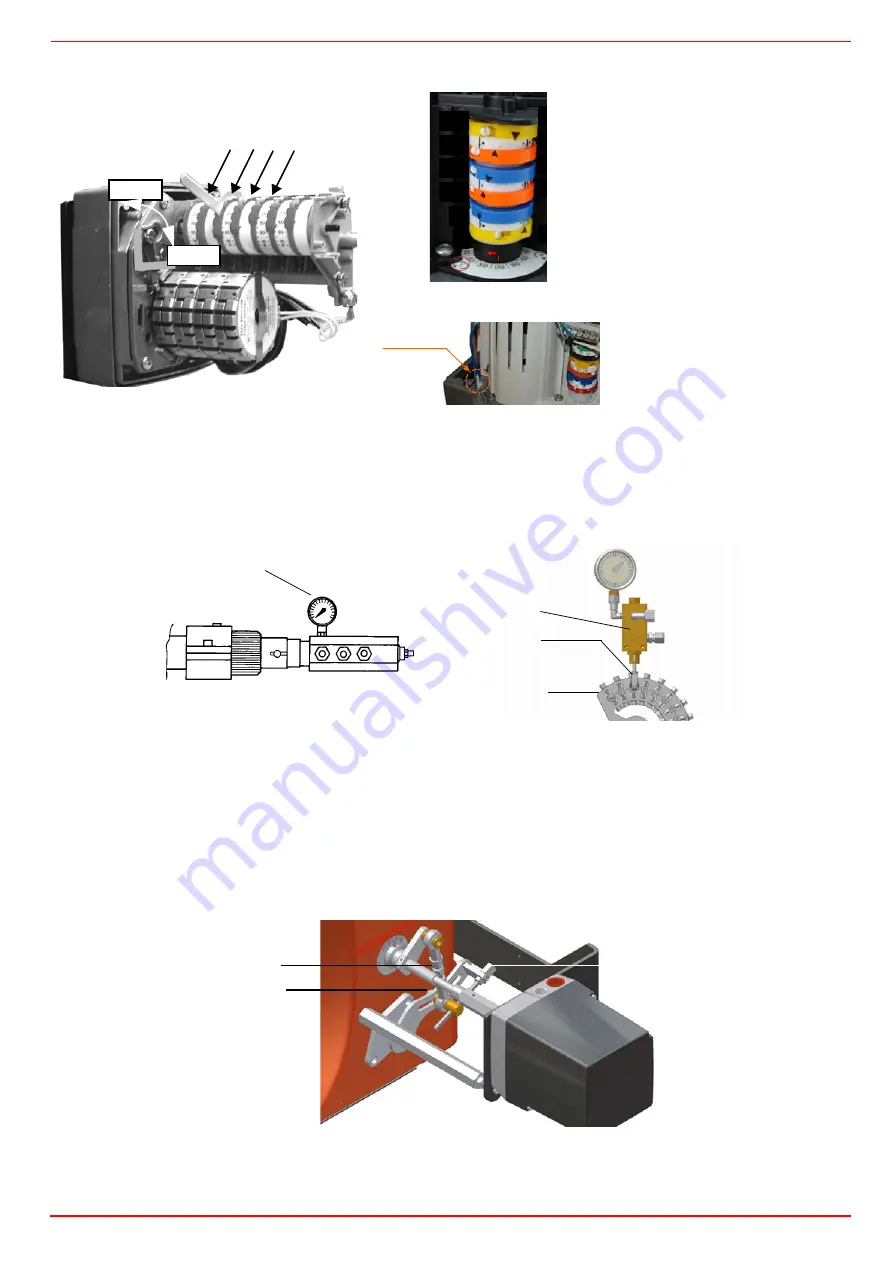

11 To adjust the

air flow rate in the high flame stage

, loose the

RA

nut and screw

VRA

as to get the desired air flow rate: moving

the rod

TR

towards the air damper shaft, the air damper opens and consequently the air flow rate increases, moving it far from the

shaft the air damper closes and the air flow rate decreases.

Note:

once the procedure is perfomed, be sure that the blocking nut

RA

is fasten. Do not change the position of the air damper

rods.

12 the air and oil rate are now adjusted at the maximum power stage, go on with the point to point adjustement on the

SV

adjusting

cam as to reach the minimum output point.

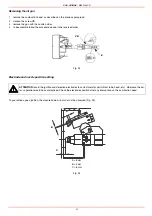

Siemens SQM10

Siemens SQM40

Actuator cams

I

High flame

II

Stand-by and Ignition

III

Low flame

IV

Stroke limitation

Fig. 20

Fig. 21

MAN

AUTO

I

II

III

IV

mensions

Dimensions in

SQM4...

I

III

II

IV

V

VI

VI

V

IV

II

III

I

MAN-AUTO

Pressure gauge port

RP

PG

V2

SV2

RA

TR

VRA

Summary of Contents for RG1025

Page 2: ......

Page 18: ...C I B UNIGAS M039144CD 18 BERGONZO NOZZLES Fig 15 ...

Page 19: ...C I B UNIGAS M039144CD 19 Fig 16 ...

Page 20: ...C I B UNIGAS M039144CD 20 Fig 17 ...

Page 21: ...C I B UNIGAS M039144CD 21 Fig 18 ...

Page 38: ......

Page 39: ......