26

6

Start the burner up by means of the thermostat series and wait unitl the pre-purge phase comes to end and that burner starts up;

7

drive the burner to high flame stage, by means fo the thermostat

TAB

(high/low flame thermostat - see Wiring diagrams), as far as

fully-modulating burners, see related paragraph.

8

Then move progressively the microswitch to higher values until it reaches the high flame position; always check the combustion

values (see next steps).

9

the nozzle supply pressure is already factory-set and must not be changed. Only if necessary, adjust the supply pressure as fol-

lows (see related paragraph); insert a pressure gauge into the port shown on Fig. 18 and act on on the pump adjusting screw

VR

(see Fig. 17) as to get the nozzle pressure at 25bar (see diagram on page 22).

10 in order to get the maximum oil flow rate, adjust the pressure (reading its value on the

PG

pressure gauge): checking always the combu-

stion parameters, the adjustment is to be performed by means of the

SV

adjusting cam screw

V

(see picture) when the cam has reached

the high flame position.

11 To adjust the

air flow rate in the high flame stage

, loose the

RA

nut and screw

VRA

as to get the desired air flow rate: moving

the rod

TR

towards the air damper shaft, the air damper opens and consequently the air flow rate increases, moving it far from the

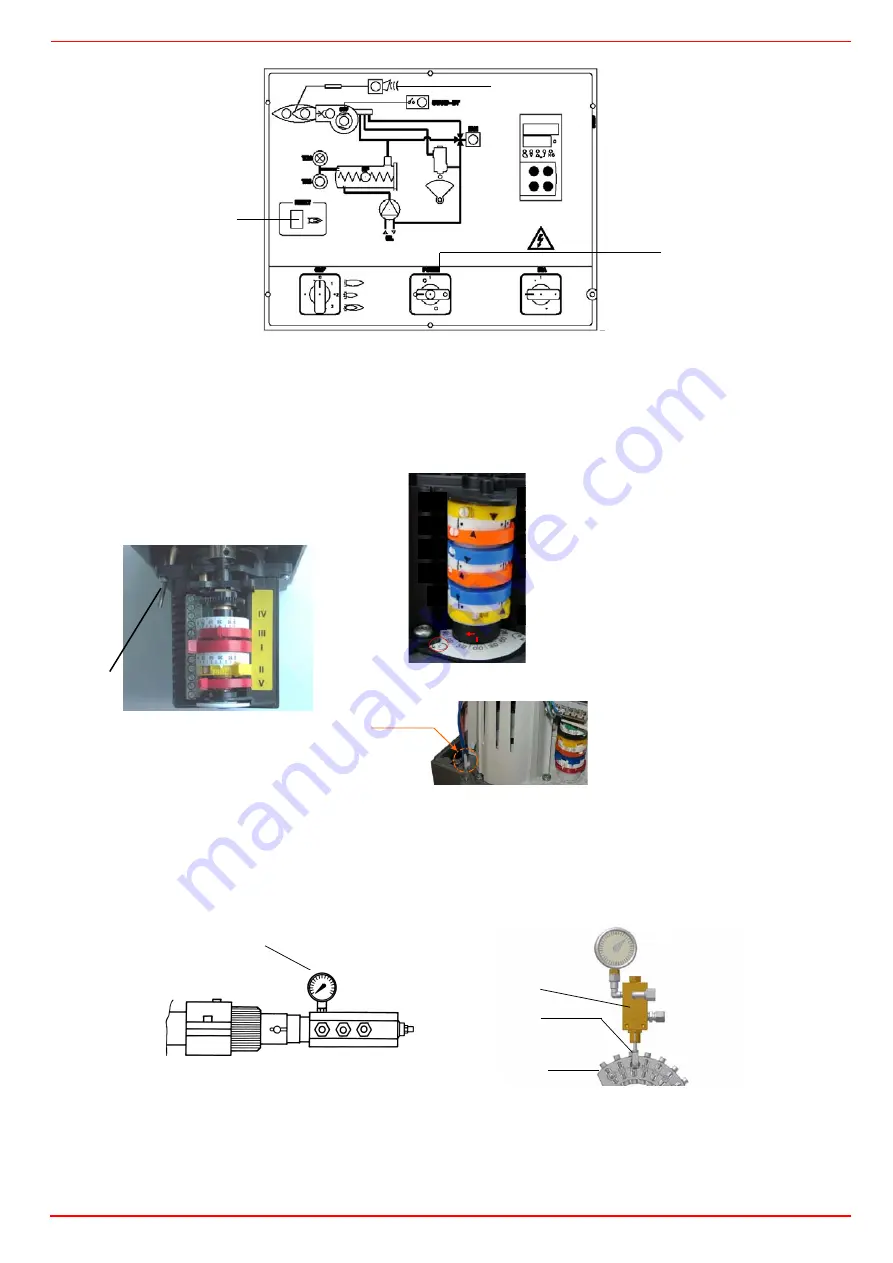

Berger STM30

Siemens SQM40

Actuator cams

I

High flame

II

Stand-by and Ignition

III

Low flame

Fig. 20

Fig. 22

A

C

B

MAN-AUTO

mensions

Dimensions in

SQM4...

I

III

II

IV

V

VI

VI

V

IV

II

III

I

MAN-AUTO

Pressure gauge port

RP

PG

V

SV