24

7 VSD

Standardization

Motor standardization (speed acquisition) allows the LMV unit to control the motor rounds at the maximum frequency signal coming from the VSD. A

temporary standardization is factory set only for test purpose. The definite standardization must be performed on site by the Service Center (only if the

fan is supplied), before the plant test.

ATTENTION: To perform standardization, the burner must be in stand-by mode, not it lockout stage. The Safety loop must be

closed (X3-04).

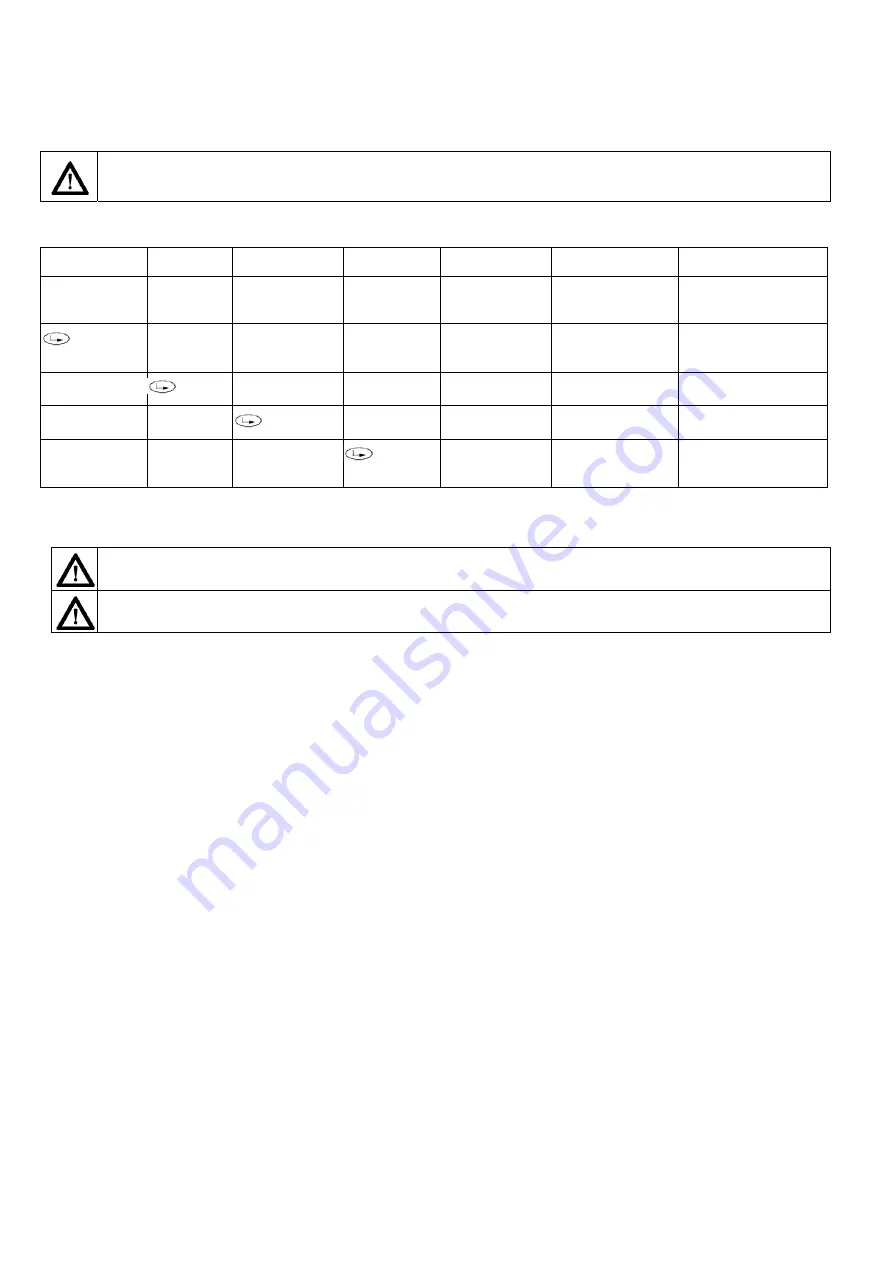

Following the below route access to the programming levels of the menu by means the Esc

1st level

2nd level

3rd level

4th level

5th level

Range

Description

Params & Display

Menu level for making the

parameter settings

VSD Module

Settings for the VSD

module

Configuration

Speed

Standardization Deactivated

Activated

Standardization process for

fan speed

By activating the standardization, without starting the burner up, the air actuator drives to ites maximum opening. Then the fan motor stars and the VSD

drives the motor to its maximum speed. The speed sensor, mounted on the motor, detects the rpm value. LMV stores the data and the motor stops.

ATTENTION: do not enter manually the rpm value of the motor data plate on parameter “StandardizedSp”.

ATTENTION: the power cable that connects VSD to motor must be screened.

Summary of Contents for RX92R-FGR

Page 49: ...Siemens LMV5x Service Manual M12920CC rev 2 1 08 2017...

Page 56: ...8...

Page 60: ...12 2 2 LMV5x program structure...

Page 87: ...39...

Page 94: ......

Page 95: ......

Page 96: ...Note Specifications and data subject to change Errors and omissions excepted...

Page 98: ...Annex1 Example for motor cable...

Page 99: ......

Page 100: ...Annex 2 Example for sensor cable...

Page 101: ......

Page 102: ......

Page 106: ......

Page 117: ...WB1 QF1 QF2...

Page 118: ......

Page 119: ......

Page 120: ......

Page 121: ......

Page 122: ...WB1 SCHEDA LED QF1 QF2...

Page 123: ......

Page 124: ......

Page 125: ......