PART I: SPECIFICATIONS

10

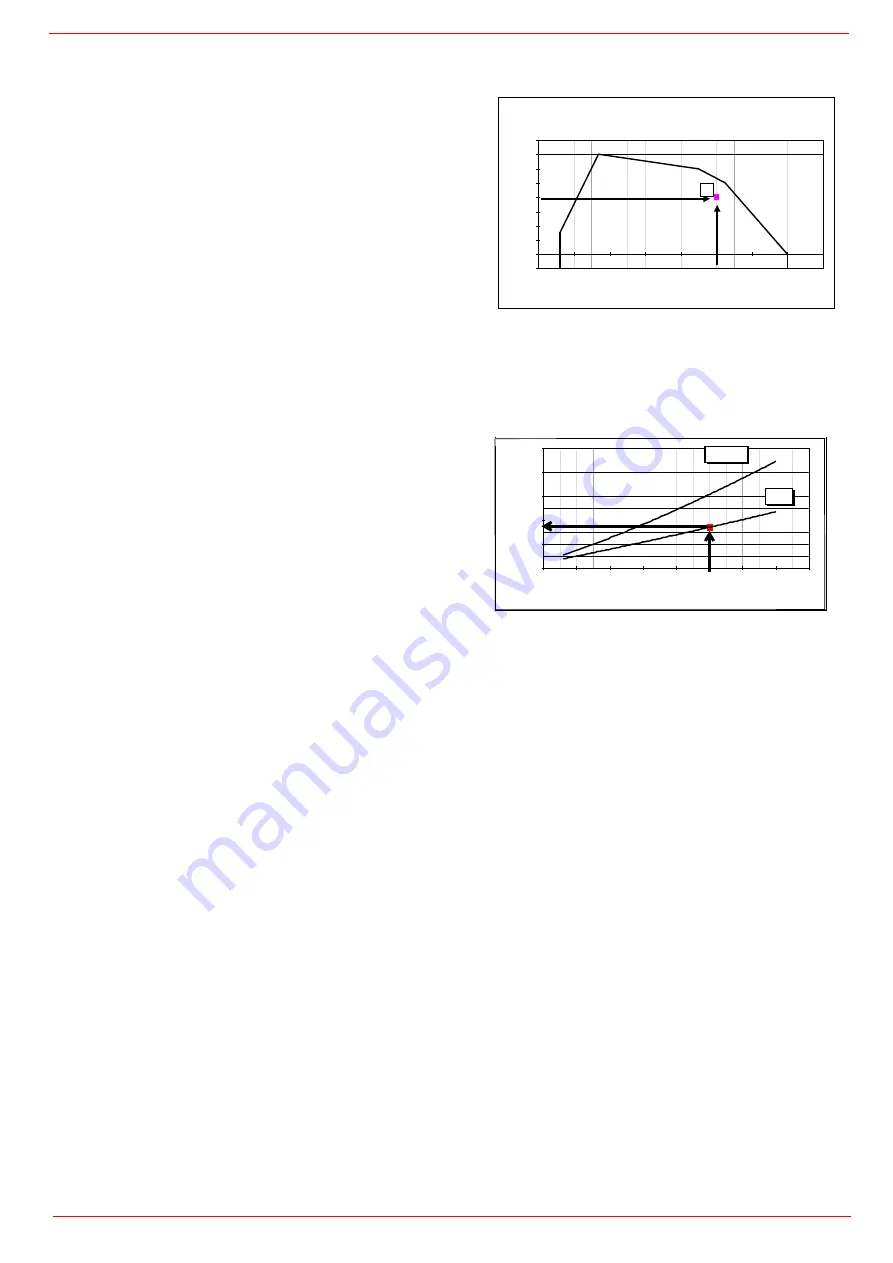

How to read the burner “Performance curve”

To check if the burner is suitable for the boiler to which it must be instal-

lled, the following parameters are needed:

furnace input, in kW or kcal/h (kW = kcal/h/860);

backpressure (data are available on the boiler ID plate or in the

user’s manual).

Example:

Furnace input: 600kW

Backpressure: 4 mbar

In the “Performance curve” diagram, draw a vertical line matching the

furnace input value and an horizontal line matching the backpressure

value. The burner is suitable if the intersection point A is inside the per-

formance curve.

Data are referred to standard conditions: atmospheric pressure at 1013

mbar, ambient temperature at 15° C.

Checking the proper gas train size

To get the input in kcal/h, multiply value in kW by 860.

Data are referred to standard conditions: atmospheric pressure at 1013mbar, ambient temperature at 15° C

NOTE:

The performance curve is a diagram that represents the burner performance in the type approval phase or in the laboratory tests, but does not

represent the regulation range of the machine. On this diagram the maximum output point is usually reached by adjsuting the combustion head to its

“MAX” position (see paragraph “Adjusting the combustion head”); the minimum output point is reached setting the combustion head to its “MIN” position.

During the first ignition, the combustion head is set in order to find a compromise between the burner output and the generator specifications, that is why

the minimum output may be different from the Performance curve minimum

To check the proper gas train size, it is necessary to the available

gas pressure value upstream the burner’s gas valve. Then subtract

the backpressure. The result is called

pgas.

Draw a vertical line

matching the furnace input value (600kW, in the example), quoted

on the x-axis, as far as intercepitng the network pressure curve,

according to the installed gas train (DN65, in the example). From the

interception point, draw an horizontal line as far as matching, on the

y-axis, the value of pressure necessary to get the requested furnace

input. This value must be lower or equal to the

pgas

value, calcula-

ted before.

Campo di lavoro bruciatori

Tipo P60 Mod. M-xx.x.IT.A.0.50 - M-.xx.x.IT.A.0.65

-1

0

1

2

3

4

5

6

7

8

100

200

300

400

500

600

700

800

900

Potenza kW

Contropressione in camera di

combustione mbar

A

backpressure

in

co

mbust

ion

ch

amber

(mb

ar)

Power kW

0

5

10

15

20

25

100

200

300

400

500

600

700

800

900

Potenza / Output (kW)

Minima pressione gas in

rete / Minimum inlet gas

pressure (mbar)

Rp 2" (50)

DN65

Power kW

min

imum

gas

pressure

in

th

e

ne

tw

or

k

m

bar

DN65

Summary of Contents for TLX2020

Page 42: ...Annex1 Example for motor cable...

Page 43: ......

Page 44: ...Annex 2 Example for sensor cable...

Page 45: ......

Page 46: ......

Page 50: ......