PART I: SPECIFICATIONS

12

Fan installation

ATTENTION! The bellows unit provided is made of canvas and is provided with blocking spacers to avoid

breaking it during installation: first place the bellows unit between flanges, then remove the spacers. Canvas has

to be stretched after the installation, but not stressed.

ATTENTION! the air duct dimensioning must be perforformed according to the flow rate, the temperature, the

distance between the fan and the burner and according to the fan features as well..

ATTENTION! It is suggested to install the fan on vibration-damping supports in order to reduce vibration

propagation.

Combustion head gas pressure curves

Combustion head gas pressure depends on gas flow and combustion chamber backpressure. When backpressure is subtracted, i

depends only on gas flow, provided combustion is properly adjusted, flue gases residual O2 percentage complies with “Recommended

combustion values” table and CO in the standard limits). During this stage, the combustion head, the gas butterfly valve and the

actuator are at the maximum opening. Refer to , showing the correct way to measure the gas pressure, considering the values o

pressure in combustion chamber, surveyed by means of the pressure gauge or taken from the boiler’s Technical specifications.

.

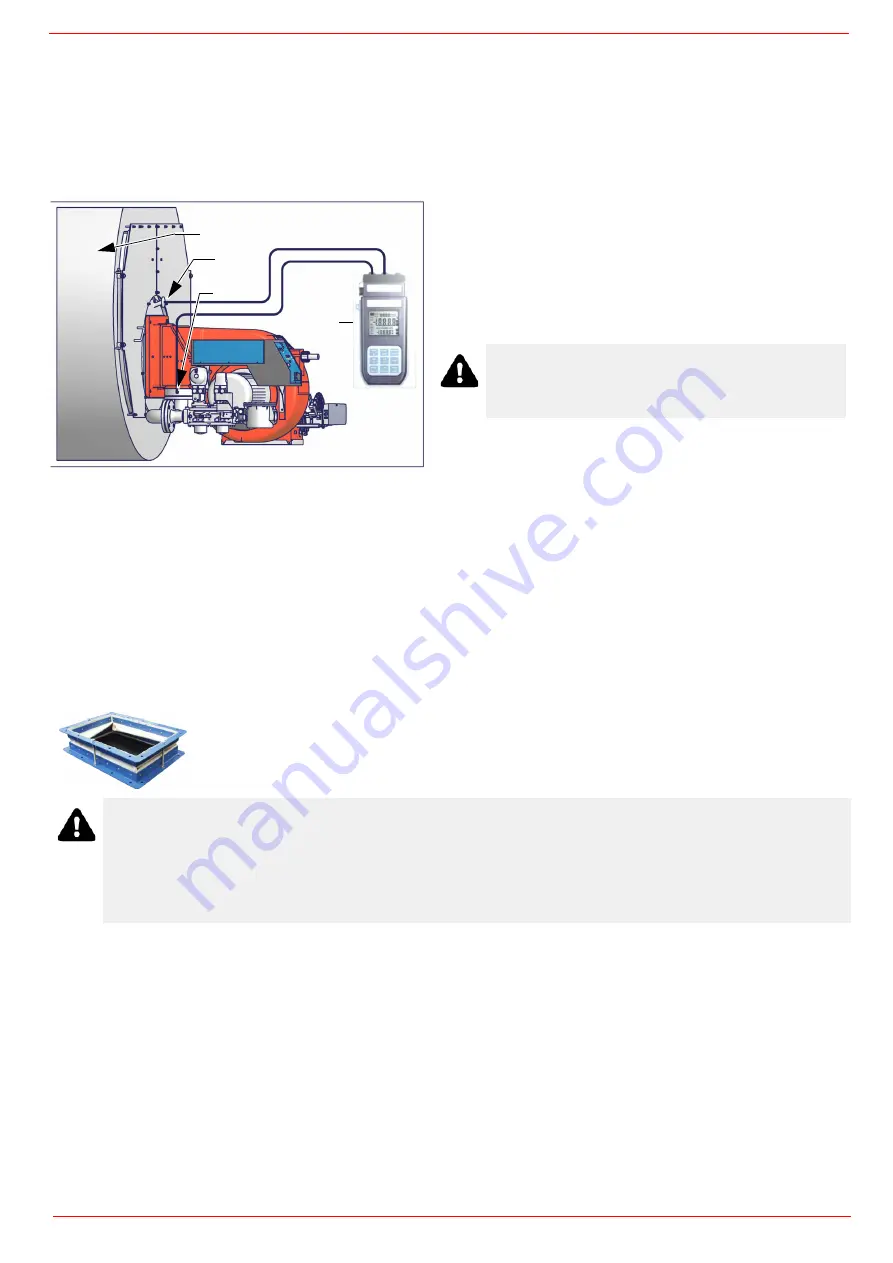

Measuring gas pressure in the combustion head

In order to measure the pressure in the combustion head, insert the pressure gauge probes: one into the combustion chamber’s

pressure outlet to get the pressure in the combustion chamber and the other one into the butterfly valve’s pressure outlet of the burner.

On the basis of the measured differential pressure, it is possible to get the maximum flow rate: in the pressure - rate curves (showed on

the next paragraph), it is easy to find out the burner’s output in Stm

3

/h (quoted on the x axis) from the pressure measured in the

combustion head (quoted on the y axis). The data obtained must be considered when adjusting the gas flow rate.

1

2

4

3

Note: the figure is indicative only.

Key

1 Generator

2 Pressure outlet on the combustion chamber

3 Gas pressure outlet on the butterfly valve

4 Differential pressure gauge

Fig. 1

ATTENTION: THE BURNED GAS RATE MUST BE

READ AT THE GAS FLOW METER. WHEN IT IS NOT

POSSIBLE, THE USER CAN REFERS TO THE

PRESSURE-RATE CURVES AS GENERAL

INFORMATION ONLY.

Connect the air duct to the burner by means of the bellows unit provided together with the burner (see the

picture below).Install the bellows units provided as explained on pages 13-14.

Summary of Contents for TLX2020

Page 42: ...Annex1 Example for motor cable...

Page 43: ......

Page 44: ...Annex 2 Example for sensor cable...

Page 45: ......

Page 46: ......

Page 50: ......