CIB UNIGAS

- M039259CA

16

to the diagram on Fig. 5, it is possible to realise that to pump an oil with 50°E viscosity at 50°C, it must be heated at about 80°C.

Pipe heating system

Pipe heating system must be provided, that is a system to heat pipes and plant components to mantain the viscosity in the pumping lim-

its. Higher the oil viscosity and lower the ambient temperature, more necessary the pipe heating system.

Inlet minimum pressure of the pump (both for supplying system and burner)

A very low pressure leads to cavitation (signalled by its peculiar noise): the pump manifacturer declares the minimum value. Therefore,

check the pump technical sheets.

By increasing the oil temperature, also the minimum inlet pressure at the pump must increase, to avoid the gassification of the oil low-

boiling products and the cavitation. The cavitation compromises the burner operation, it causes the pump to break too. The diagram on

Fig. 6 roughly shows the inlet pump pressure according to the oil temperature.

Pump operating maximum pressure (both for the supplying system and burner)

Remember that pumps and all the system components through which the oil circulates, feature an upper limit. Always read the techni-

cal documentation for each component. Schemes on Fig. 8 and Fig. 9 are taken from UNI 9248 "liquid fuel feeding lines from tank to

burner" standard and show how a feeding line should be designed. For other countries, see related laws in force. The pipe dimensio-

ning, the execution and the winding dimensioning and other construcitve details must be provided by the installer.

Adjusting the supplying oil ring

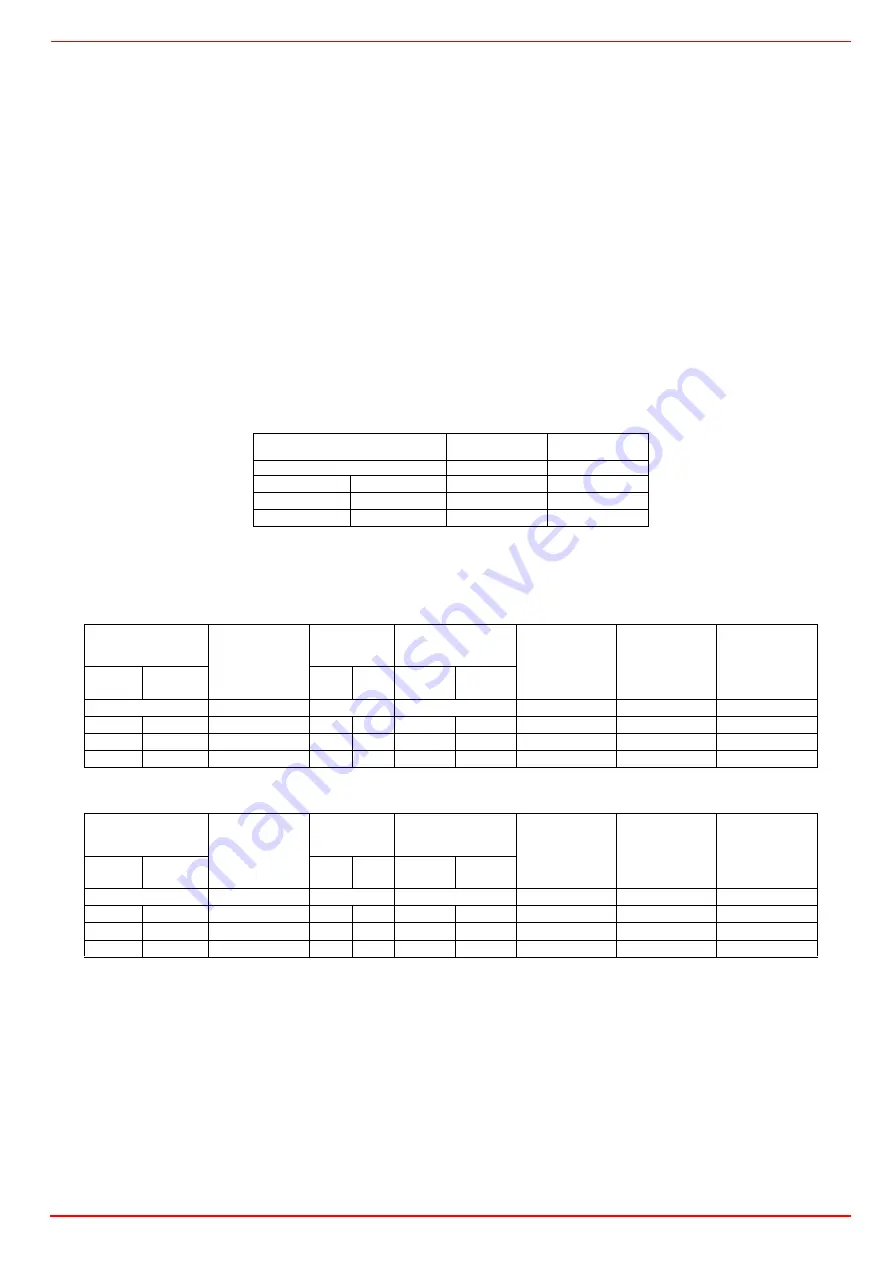

According to the heavy oil viscosity used, in the table below indicative temperature and pressure values to be set are shown.

Note:

the temperature and pressure range allowed by the supplying ring components must be checked in the specifications table of the

components themselves.

Tab. 1

Burner adjustments

The table below shows indicative values of temperature and pressure to be set on the burner devices, according to the viscosity of the

heavy oil used. The oil temperature should be set on TR resistor thermostat in order to get about 1.5°E viscosity at the nozzle.

Tab. 2 - Fluidics WR2 nozzle

Tab. 3 - Bergonzo A3 nozzle

HEAVY OIL VISCOSITY AT 50 °C

PIPELINE

PRESSURE

PIPELINE

TEMPERATURE

cSt (°E)

bar

°C

< 50 (7)

1- 2

20

> 50 (7)

< 110 (15)

1- 2

50

> 110 (15)

< 400 (50)

1- 2

65

VISCOSITY

AT 50 °C

NOZZLE

PRESSURE

MEASURED IN

THE GUN

RETURN

NOZZLE

PRESSURE

TEMPERATURE ON

THE PRE-HEATING

RESISTORS

TEMPERATURE

OF THE

RESISTORS

SAFETY

THERMOSTAT

TRS

TEMPERATURE

ON THE OIL

ENABLING

THERMOSTAT

TCN

TEMPERATURE

ON THE PLANT

ENABLING

THERMOSTAT

TCI

min.

max.

min.

max.

cSt (°E)

bar

bar

°C

°C

°C

°C

< 50 (7)

25

7-9

19-20

100

115

170

80

50 - 60

> 50 (7)

< 110 (15)

25

7-9

19-20

125

140

190

100

60 - 80

> 110 (15)

400 (50)

25

7-9

19-20

145

160

190

110

70 - 90

VISCOSITY

AT 50 °C

NOZZLE

PRESSURE

MEASURED IN

THE GUN

RETURN

NOZZLE

PRESSURE

TEMPERATURE ON

THE PRE-HEATING

RESISTORS

TEMPERATURE

OF THE

RESISTORS

SAFETY

THERMOSTAT

TRS

TEMPERATURE

ON THE OIL

ENABLING

THERMOSTAT

TCN

TEMPERATURE

ON THE PLANT

ENABLING

THERMOSTAT

TCI

min.

max.

min.

max.

cSt (°E)

bar

bar

°C

°C

°C

°C

< 50 (7)

20

5-7

11-13

100

115

170

80

50 - 60

> 50 (7)

< 110 (15)

20

5-7

11-13

125

140

190

100

60 - 80

> 110 (15)

400 (50)

20

5-7

11-13

145

160

190

110

70 - 90

Summary of Contents for TN90

Page 2: ......

Page 21: ...CIB UNIGAS M039259CA 21 Fig 9 Hydraulic diagram 3ID0014 Two or more burners configuration...

Page 34: ...CIB UNIGAS M039259CA 34...

Page 54: ......

Page 63: ......

Page 64: ......

Page 65: ...RWF50 2x RWF50 3x User manual M12922CB Rel 1 0 07 2012...

Page 80: ...16 Note Specifications and data subject to change Errors and omissions excepted...

Page 81: ...KM3 Modulator USER MANUAL M12927CA Rel 1 0 10 2020...

Page 82: ...M12927CA MOUNTING 2...

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......