CIB UNIGAS

- M039259CA

5

GENERAL FEATURES

This series of industrial burners is designed for all those applications that require big-sized air fans or air-flue heat exchangers to be

installed in sound-proof areas to reduce noise. They can be provided with built-in or separately-mounted control panel (console or wall-

mounted.

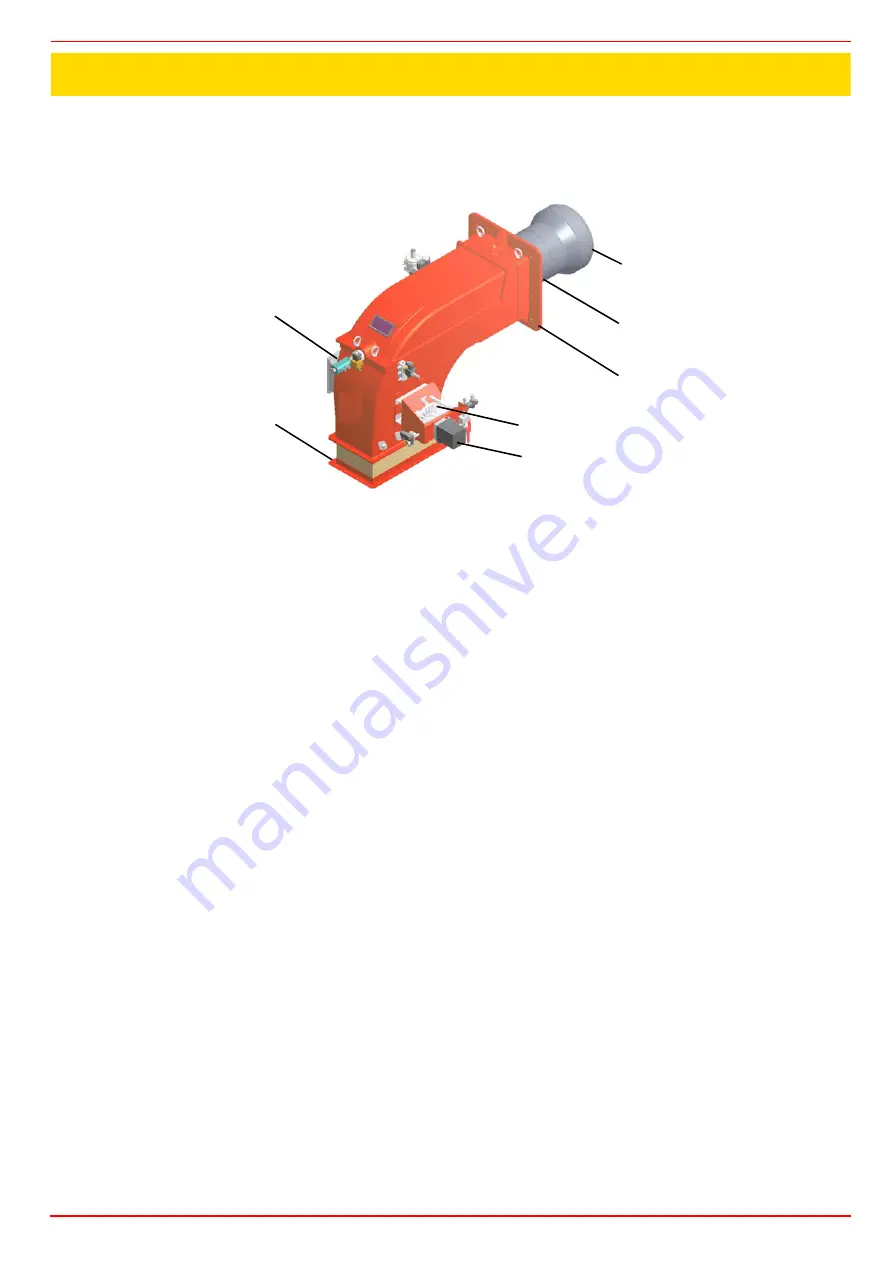

Fig. 1

1

Combustion head

2

Blast tube

3

Burner flange

4

Adjusting cam

5

Actuator

6

Air inlet flange

7

Oil gun

8

Ignitor gas train

How to choose the burner

To check if the burner is suitable for the boiler to which it must be installled, the following parameters are needed:

fuel

furnace input, in kW or kcal/h (kW = kcal/h / 860);

boiler type;

combustione head type (reverse flame or three phase)’

temperature or pressure of the thermal carrier fluid

Comburent air temperature

Air duct positioning

Pressure in the combustion chamber

Elevation (altitude) of burner installation

Gas train (only for gas burners)

Pumping unit (only for light-oil or heavy-oil burners)

Air fan

Bilt-in or separated control panel

backpressure (data are available on the boiler ID plate or in the user’s manual).

Burners provided with built-in control panel are designed for IP40 index of protection. For other values of IP, please contact the CIB

UNIGAS Technical Dpt.

PART I: INSTALLATION MANUAL

1

2

7

5

3

4

6

Summary of Contents for TN90

Page 2: ......

Page 21: ...CIB UNIGAS M039259CA 21 Fig 9 Hydraulic diagram 3ID0014 Two or more burners configuration...

Page 34: ...CIB UNIGAS M039259CA 34...

Page 54: ......

Page 63: ......

Page 64: ......

Page 65: ...RWF50 2x RWF50 3x User manual M12922CB Rel 1 0 07 2012...

Page 80: ...16 Note Specifications and data subject to change Errors and omissions excepted...

Page 81: ...KM3 Modulator USER MANUAL M12927CA Rel 1 0 10 2020...

Page 82: ...M12927CA MOUNTING 2...

Page 106: ......

Page 107: ......

Page 108: ......

Page 109: ......

Page 110: ......

Page 111: ......

Page 112: ......