PART I: SPECIFICATIONS

6

Blast tube

URB burner series is supplied with a refractory blast tube made by a set of preformed and precooked refractory bricks including from

average 59% Al

2

O

3

.

The tiles must be mounted at site on the boiler front wall by professional and qualified personnel, according to CIB UNIGAS lay-out dra-

wings and recommendations.

Gas lances and nozzles

The natural gas flow, regulated by a motorised butterfly valve, reaches a gas ring and, passing through flexible hoses and manual val-

ves, it enters into several lances to be guided up to the gas nozzles.

The stainless steel nozzle series is distributed all around the refractory blast tube, in order to optimize the gas distribution into the com-

bustion chamber, for an high combustion efficiency and to limit the production of thermal oxides of nitrogen (NOx) and carbon mono-

xide (CO).

Each lance, so each nozzle, can be adjusted and removed during the operation in the plant (start-up and maintenance).

Windbox and Register Assembly

The burner windbox is assembled of heavy gauge welded steel.

Insulated windboxes for use with pre-heated combustion air are available.

The offered machines are forced natural gas burners, designed with a single or a double air registers in reference to the output that the

machine must develop.

Two inspection doors are provided. They are not only useful for the maintenance, but they also offer the possibility to switch the posi-

tion of the air damper to one of them, if the lay-out of the plant requires any adjustments on the site, or to add a second damper in case

of a second combustion air stage or a flue gas recirculation where required.

Burner registers are designed and mounted in the windbox to permit an easy access for maintenance and to ensure a balanced air

distribution in the windbox.

Each register is complete with a manual control handle and a mechanical indicator. The air registers will be adjusted in the proper posi-

tion at the start-up, to ensure a proper flame distribution in the combustion chamber and an optimum mixing of fuel with turbulent air, to

reach an high efficiency in terms of heat exchange and emission values.

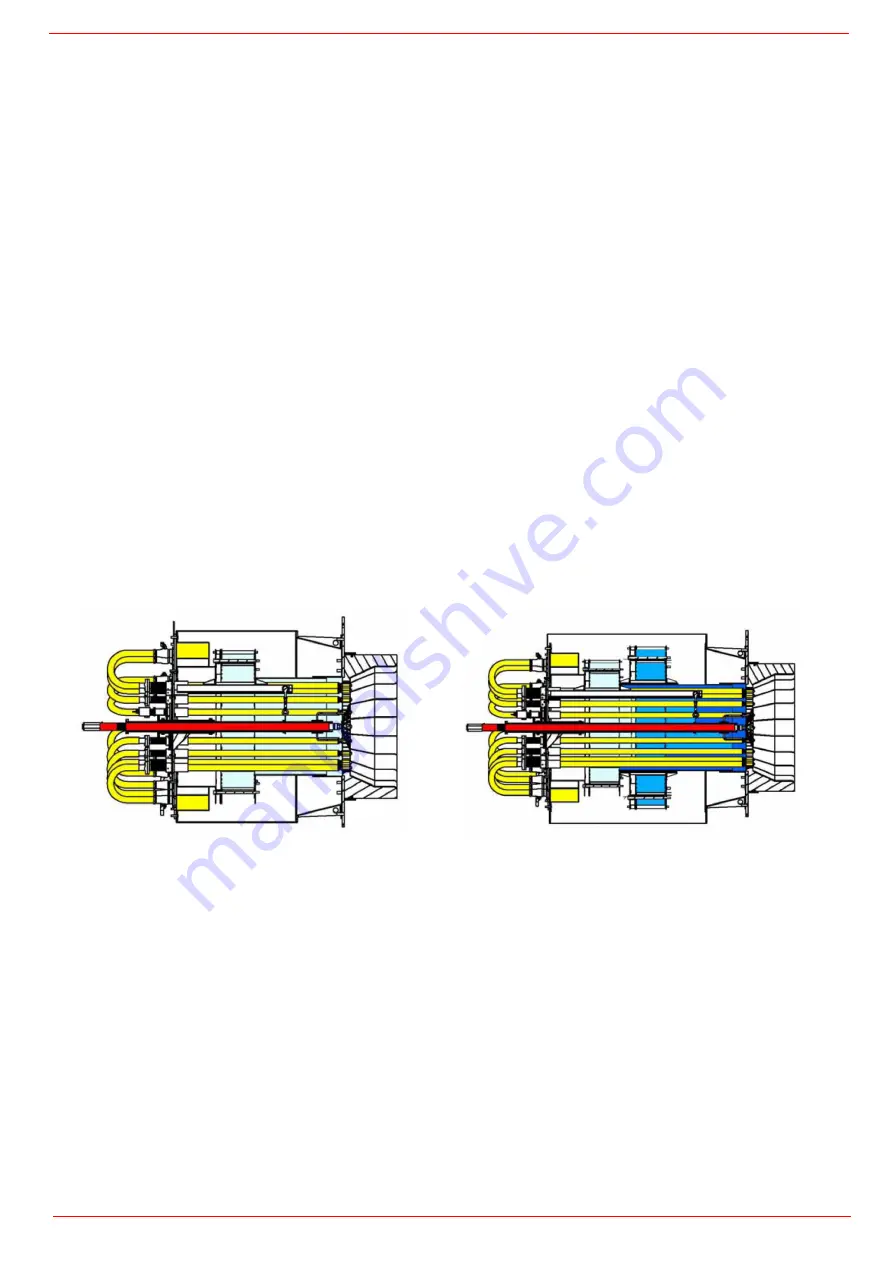

Single register configuration

Double register configuration

Summary of Contents for URB40

Page 37: ......

Page 38: ......

Page 39: ......

Page 42: ...Annex1 Example for motor cable...

Page 43: ......

Page 44: ...Annex 2 Example for sensor cable...

Page 45: ......

Page 46: ......

Page 50: ......