10

Inspection of the sanding belt

•

The sanding belt gets worn out often. Worn out belt does not provide you with the proper sanding action

and the efficiency of the sanding process is reduced significantly. Change the sanding belt as soon as

you see first signs of wear and tear.

•

Inspect and clean the ventilation openings regularly to prevent engine overheating. Overheating is caused

by clogged ventilation openings.

•

Keep your tools clean. Dirt may enter the inner mechanism of your machine and cause damage.

•

Do not use aggressive cleaning solution or paint thinners to clean the machine.

•

Clean plastic parts with cloth dipped in soup water.

•

Clean and lubricate metal surfaces with a cloth dipped in paraffin oil.

•

If you are not using your machine, lubricate it with suitable grease and store it in a dry place to prevent

corrosion.

In accordance with the applicable law, carbon brushes and saw blades are considered expandable

material and are not covered by the warranty policy.

Detailed description of the use of this device is not included in this manual, because the manufacturer /

distributor assumes that the user is experienced in similar type of work. Also according to the applicable

law, this device is considered as a commonly sold and used tool. If the user is unfamiliar with the use of

this device, we recommend finding out more information about using this device at the Department of

work safety.

Used hydraulic fluids must be disposed off in accordance with the Law of waste disposal management.

When the operational life of your device is over, dispose off it in accordance with valid rules and regulations.

Your product is made of metal and plastic parts that may be recycled when separated.

1. Disassemble all parts.

2. Separate all parts according to the material they are made of (e.g. metals, rubber, plastics, etc.).

Take the separated parts to the recycling facility near you for further processing.

3. Electrical waste (used electrical power tools, electric motors, recharging equipment, electronics,

accumulators, batteries etc.).

Dear customer. In accordance with the valid regional rules and regulations describing the management of

electrical waste, electrical waste is considered dangerous.

Disposal of electrical waste must be therefore handled as dangerous waste in accordance with waste

management rules valid in the state you are in.

It is prohibited to mix electrical waste with regular household waste.

You may return your used electrical appliance to a recycling facility near you. More information about

electrical and dangerous waste disposal may be obtained from your local authority or from the Internet.

DISPOSAL

7

Choosing the right sanding belt

•

AA - Used for sanding or polishing of wooden or metal surfaces.

•

CC - Used for sanding or polishing of slate-like stones, plastic or concrete surfaces and non-ferrous

materials.

Sanding grain size

Type of sanding….

Sanding grain size

Type of sanding….

•

AA40

•

Hard

•

CC40

•

Hard

•

AA60

•

CC60

•

AA80

•

Medium

•

CC80

•

Medium

•

AA100

•

CC100

•

AA120

•

CC120

•

AA150

•

Fine

•

CC150

•

Fine

•

AA180

•

CC180

•

AA240

•

CC240

•

If you do rough sanding use sanding belt with grain size between 40 - 60. For fine sanding work or

polishing use smaller grain size belt (60 and above). See the chart above. If the surface of the work piece

is not evenly flat, use hard sanding belt to flatten the surface first. For finishing use fine grain sanding belt.

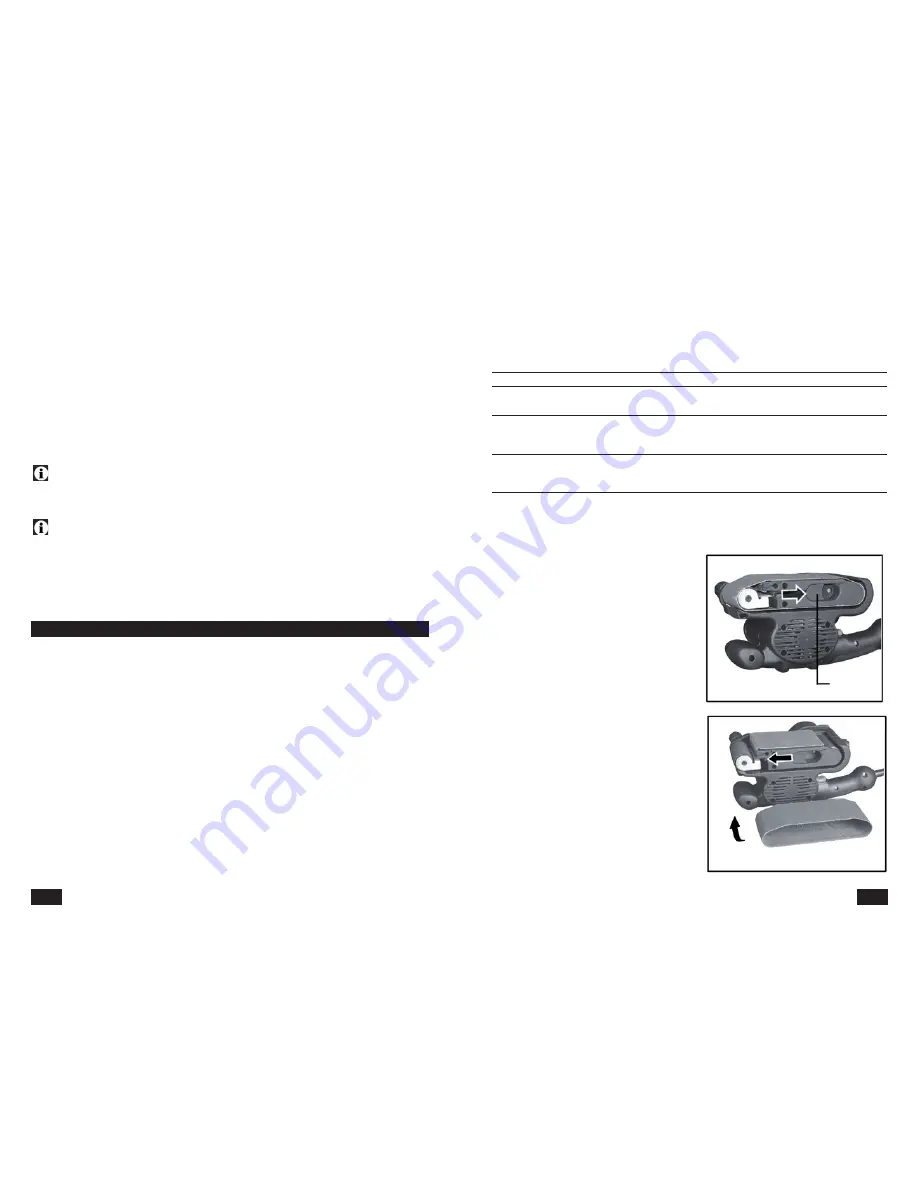

Fixing the sanding belt in place

•

Warning:

Before putting the sanding belt on,

make sure the power cable is disconnected from

the wall outlet and the main switch/trigger is off.

•

Pull the handle to release the belt-tensioning

device.

•

Place the new belt on the driving drum.

•

During the belt placement make sure that the

arrow on the back side of the sanding belt

points in the same direction as the arrow on the

machine to ensure the correct turning direction.

•

When the belt is fixed in place, return the handle

back to its original position.

Handle