Summary of Contents for 36200 Series

Page 8: ...From the library of Superior Sewing Machine Supply LLC ...

Page 18: ... 2 1 I I l l J L1 From the library of Superior Sewing Machine Supply LLC ...

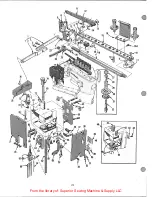

Page 20: ...20 From the library of Superior Sewing Machine Supply LLC ...

Page 22: ...22 From the library of Superior Sewing Machine Supply LLC ...

Page 24: ... 24 I i 16A I I I 0 From the library of Superior Sewing Machine Supply LLC ...

Page 26: ...12 26 I I 16A I I I 0 7 From the library of Superior Sewing Machine Supply LLC ...

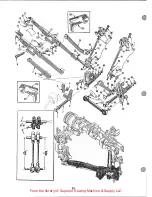

Page 28: ...8 From the library of Superior Sewing Machine Supply LLC ...

Page 30: ...m 41 43 37 30 From the library of Superior Sewing Machine Supply LLC ...

Page 32: ...32 From the library of Superior Sewing Machine Supply LLC ...

Page 34: ...34 From the library of Superior Sewing Machine Supply LLC ...

Page 36: ...36 From the library of Superior Sewing Machine Supply LLC ...

Page 38: ...J 5 12 9 7 11 16 18 15 13 38 From the library of Superior Sewing Machine Supply LLC ...

Page 40: ...40 From the library of Superior Sewing Machine Supply LLC ...

Page 42: ...42 From the library of Superior Sewing Machine Supply LLC ...