19

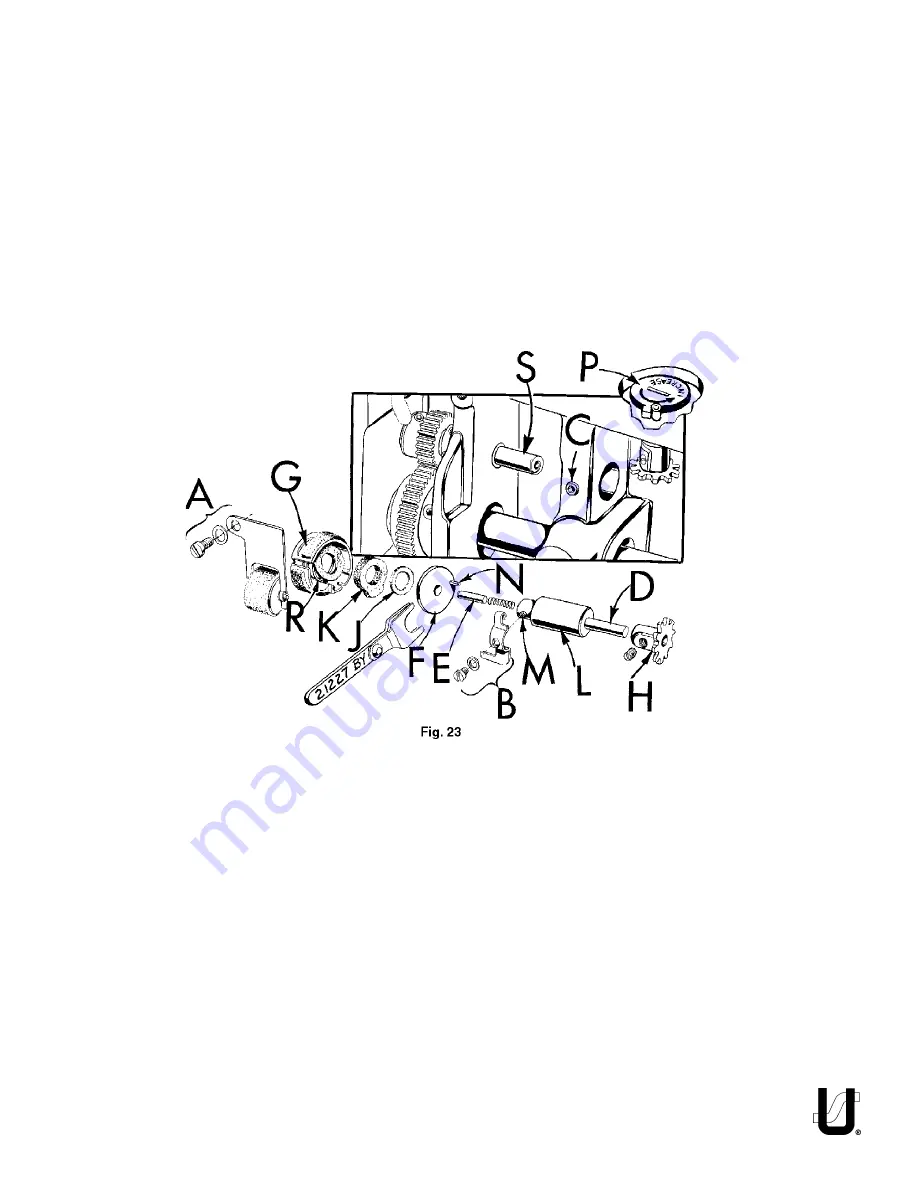

HOOK SHAFT (CONT.)

To reposition the hook shaft, loosen the set screws of the pinion and collar and establish the 9/16 inch

dimension. Move the pinion and thrust washer against the left bushing, and after making certain one of the

set screws in on the shaft FLAT, tighten both screws securely. Liberally coat the collar and its washer with

oil and press the collar away from the pinion so as to remove all end play and tighten both set screws

securely.

Hook oiling is accomplished by a high speed rotary pump on the end of the hook shaft. The quantity of oil

supplied to the hook is regulated by the longer or shorter path the oil is required to travel through the

metering felt of metering cup (G, Fig. 23). (Increase or decrease of oil supply is controlled by a dial (P, Fig.

23) with an arrow marked "INCREASE", found below the cloth plate.) The hook oil feed roller (A, Fig. 23) which

rests against the metering cup felt serves not only to feed oil to the unit from the oil reservoir, but filters the

oil as well.

REMOVAL OF OILING DEVICE

The following steps are necessary to remove hook oiling device:

1.

Remove hook oil feed roller (A, Fig. 23).

2.

Remove hook oil control finger (B).

3.

Apply finger pressure to hook oil control shaft (D) to prevent loss pump disc pivot pin (E); using Allen

wrench, loosen set screw (C). Move assembly slowly to right, being careful not to drop pivot pin

located on the end of the hook oil control shaft. When pivot pin is clear of pump disc (F), disc is free

to fall.

4.

Remove metering cup (G) along with oil supply felt (K) and air seal felt (J).

5.

Remove cop (H) from hook oil control shaft.