Part No.

D e s c r i p t i o n

A m t .

Req.

Ref.

N o .

43

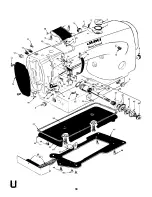

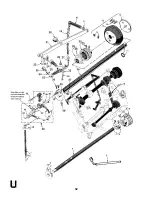

FEED ROLLER DRIVING PARTS

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

*18.

*-

19.

*20.

*-

21.

22.

23.

24.

25.

26.

27.

28.

29.

63962H

22894V

39552C

660-318

660-207

63962L

63962K

22878

63962J

22525C

22894J

63962B

22597A

63962A

63962

61248H

531

63949-39

63949-37

18-500

63949-41

63949-43

18-500

63939

63939H

22652B-10

63939A

61339D

95

63982E

22517B

Lower Reduction Gear .................................................................................

Set Screw ...............................................................................................

Thrust Washer ...............................................................................................

Truarc Ring ...................................................................................................

"O" Ring ........................................................................................................

Middle Reduction Gear .............................................................................

Upper Reduction Drive Dear ........................................................................

Set Screw ...............................................................................................

Upper Reduction Driven Gear ......................................................................

Screw .....................................................................................................

Set Screw ...............................................................................................

Upper Reduction Gear Shaft ........................................................................

Set Screw ......................................................................................................

Middle Reduction Gear Stud ........................................................................

Lower Reduction Gear Shaft ........................................................................

Thrust Collar .................................................................................................

Screw .....................................................................................................

Upper Stitch Regulating Gear, for Styles 63900M, T .......................................

Upper Stitch Regulating Gear, for Styles 63900W, AE ....................................

Set Screw ...............................................................................................

Lower Stitch Regulating Gear, for Styles 63900M, T .......................................

Lower Stitch Regulating Gear, for Styles 63900W, AE ....................................

Set Screw ...............................................................................................

Top Feed Roller Drive Shaft Bushing Housing ................................................

Top Feed Roller Drive Shaft Bushing ........................................................

Screw ...........................................................................................................

Top Feed Roller Drive Shaft ...........................................................................

Lower Feed Roller Drive Gear .......................................................................

Set Screw ...............................................................................................

Cloth Plate Extension, for Style 63900W, AE ..................................................

Screw, for Style 63900W, AE ..........................................................................

30. thru 52. see following page.

*

See page 13 "Gear Chart", for the gear combinations to produce stitches per inch, other

than the ones indicated.

†

Available as extra send and charge item.

1

2

2

2

1

1

1

2

1

3

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

2

1

3