Instruction Manual

40

80

Optical flame fire detector FD 8040 is designed to provide early warning of a fire condition responding to open

flame. The fire detector reacts within the light spectrum of the flame and has maximum sensitivity of the

infrared range. The opearation principle is based on the reception of flame emissions with their typical flicker

frequency within the whole spectrum range. The infrared sensor signal - amplified, filtered and shaped is

being sent to the time delay circuit. If the flame impact has decreased during the time delay , the fire detector

dos not activate.

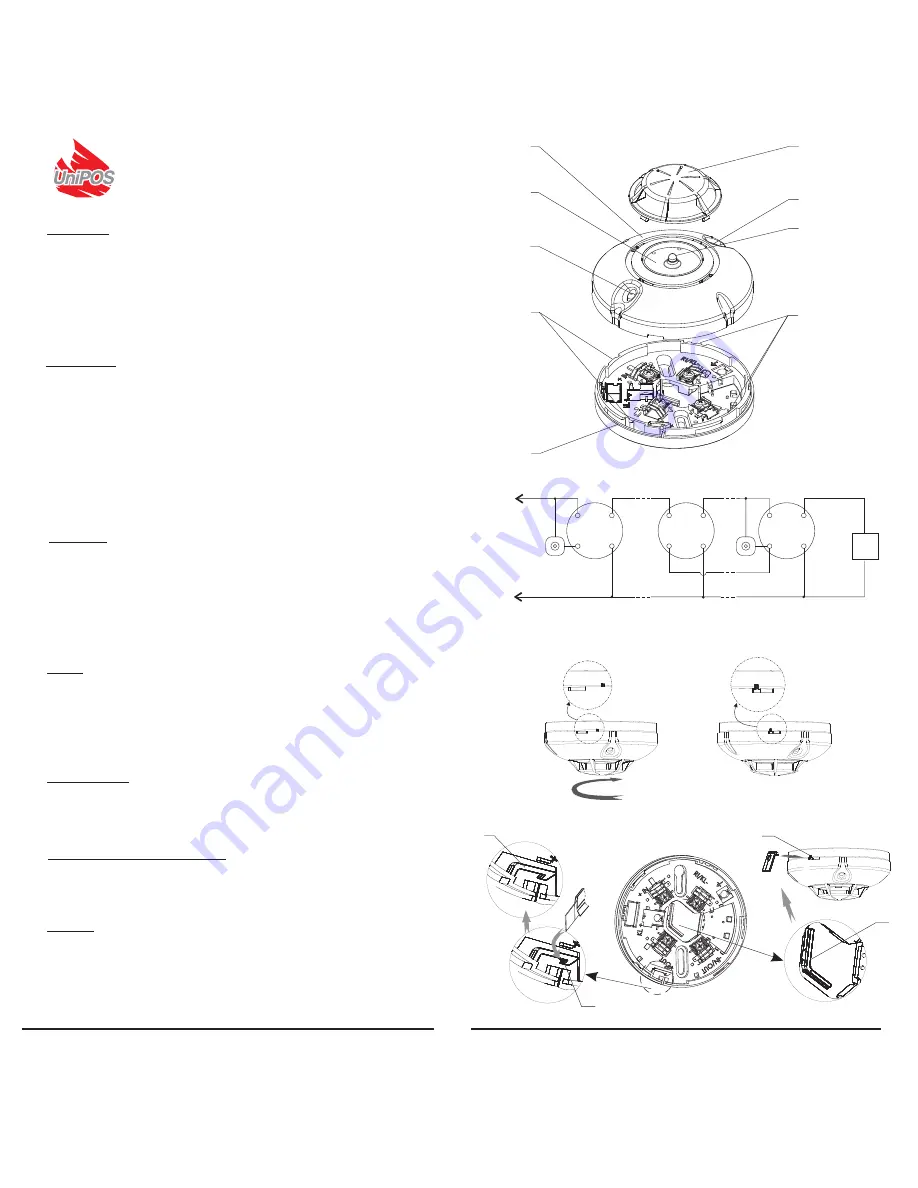

The fire detector consists of (fig.1) printed board, mounted in a plastic body with optical filter and bottom side.

The flat point pivot

screw (optional) prevents the fire detector of unauthorized removal. A 2 mm tip

screwdriver is required for locking and unlocking. The two red LEDs of the fire detector (fig.1) are indicating

Fire condition, providing 360 angle visibility. It is recommended that the fire detectors are mounted in

premises, where a possible development of fire condition is supplemented by flame. Avoid mountong in

premises with flickering lights. The fire detectors shall be mounted on the ceiling in a way, that do not alow

explosure to direct sunlight.

INTRODUCTION

Supply voltage

(from12- to30)V DC

Current consumption in Duty Mode

300 μA

Current consumption in Fire condition

- with a base type 8000 & 8000D

8mA/12V DC;- 25mA/ 30V DC

-

with a base type 8000R & 8000DR

18mA/12V DC;- 55mA/ 30V DC

Sensitivity

in accordance with EN54-10, class 2 (IR)

Time delay

T-10s ( optional T-5s;T-20s)

Protected area

Angle of visibility 45o

Type of the line connection

two-wire

Degree of protection

IP 40

Operation Temperature Range

from Minus 10 C to 55 C

o

o

Relative humidity resistance

C

(92±3)% at 40

o

Dimensions (base type 8000 included)

100mm h 47 mm

Ø

Output in Alarm condition

Terminal RI/KL for RI31 or RI31S

Cross section of the connection wire

(0.8-1.5mm2)

TECHNICAL DATA

Fire detector FD8040 is to be used with base types 8000 (standard base), 8000D (with schottky diode),

8000R ( with relay output ), 8000 DR (with schottky diode and resistor 500) or 8000L (with resistor 510)

When mounting the fire detector and the base observe the following sequence :

Fix the base to the ceiling of the protected premise using fixing screws and wood screws.

Complete the electrical wiring as shown on (fig 2.), and according to the rational design of the premise.

Fix the fire detector to the base by means of bayonet joint (fig1,pos1). When fixing, make sure that the

bench mark of the detector stands about 20 mm before the respective bench mark of the base so that the

plastic channels fully coincide (fig1,pos2), then rotate clockwise to complete location (fig3,pos1). The

bench marks should fully coincide (fig3,pos2).

Lock the detector (fig4.) head to the base by screwing the flat pivot point screw, using a specialized

screwdriver in clockwise direction to complete location, ensure not to over tighten. Unlock by unscrewing

(pos.4) the flat pivot point screw until the detector's head is released from the base.

INSTALLATION

TESTING

The fire detector shall be tested after installation, as a part of the Fire Alarm System of the premise or

after performing service schedule , in the following sequence :

1.Power supply the fire detector from the fire alarm line,to which it is mounted. The supply voltage value

is given in section Technical data of the instruction manual herein. Supply voltage can be provided by the

Fire alarm panel or by an auxiliary source 24V DC/0,1A.

2.Use a tester for flame detectors after a minute. In 30 seconds the LEDs shall be illuminated (Fire

condition).

3.Cut off the power supply of the detector for a while about 2 seconds or reset the fire panel . It should

remain in duty mode and ready for new activation after 30 seconds.

SERVICE SCHEDULE

1. Inspection for visible physical damages weekly

2. Satisfactory Operation test weekly

3. Check and clean dust contaminations every 6 months

*

* Remove the detector from the base , than remove the chamber from the detector (fig1pos6.)You can

use for a cover a cleaning materials, washing and drying.The optical chamber and the photodiod you

have to clean with clean cloth .

PACKING, STORAGE AND TRANSPORTATION

1. Each device is to be placed in separate package, together with the instruction manual.

2. The flame detectors should be stored packaged in dry store premises аt temperature from 0 to 35 C

o

o

and relative humidity resistance up to 85% in non-aggressive environment, microorganisms or vibrations.

Shelf life -10 years.

3.The fire detectors should be transported in transport packing, observing the transportation markings on

the boxes.

WARRANTY

The warrant period is 36 months from the date of purchase.

The manufacturer guarantees the normal operation of the fire detector providing that the requirements of

the instruction manual herein have been observed.

The manufacturer does not bear warranty liabilities for damages caused through accidental

mechanical damage, misuse, adaptation or modification after production. The manufacturer bears

warranty liabilities for damages in the fire detector caused through manufacturer's fault only.

OPTICAL FLAME FIRE DETECTOR

FD 8040

fig.3.1

fig.4

5

3

6

2

3

7

3

2

1

4

fig.1

1

2

fig.2

fig.3.2

FD 8040

FD 8040

RI 31-n

+

-

+OUT

+IN

-IN/OUT

RI/KL

-IN/OUT

RI/KL

FD 8040

-IN/OUT

RI/KL

RI 31-

1

L

L

+OUT

+IN

+OUT

+IN

4

EOL

Producer UniPOS Ltd

http://www.unipos-bg.com

:

.Bulgaria,5800 Pleven, San Stefano 47 Str.,

Producer UniPOS Ltd

http://www.unipos-bg.com

:

.Bulgaria,5800 Pleven, San Stefano 47 Str.,