2.2 Door Hinging

If you need to change the door hinging to facilitate access

into the Refrigerator proceed as follows;

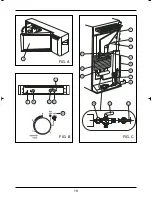

1 - Remove upper hinge cover (E1).

2 - Remove upper hinge (E2).

3 - Remove freezer door (E12).

4 - Remove middle hinge (E3).

5 - Remove refrigerator door (E13).

6 - Remove console cover (E11).

7 - Remove console (E5).

Attention: before removing the console, loosen the flame

display/visor (E7).

8 - Remove lower hinge (E4).

9 - Remove the hinges slot caps - upper, middle and

lower - from the left side and place them in the

respective right side slots.

10 - Fix the lower hinge (E4) on the left side of the

product.

11 - Fix the console (E5).

Attention: do not forget to replace the display/visor (E7).

12 - Using a sharp knife, cut out the upper left corner of

the console cover to settle the lower hinge (see

cutting instructions in Fig. E).

13 - Fit the refrigerator door (E13) on the lower hinge (E4).

14 - Fit the middle hinge (E3) together with the refrigerator

door.

15 - Fit the freezer door onto middle hinge.

16 - Close the freezer door and check for alignment.

17 - Fix the upper hinge.

Note: make sure the gasket sealing is Ok.

If necessary, adjust hinge adjustment.

18 - Fix upper hinge cap.

2.3 Installing the Refrigerator

This Refrigerator must be installed in accordance with

local codes or installation must comply with:

•

The National Fuel Gas Code, ANS Z223.1 in the USA.

•

Installation Code for Propane Burning Appliances and

Equipment CAN/CGA B149 in Canada.

•

This Refrigerator is only designed for domestic use.

It is your total responsibility if you intend to use it in a

trailer.

02

To ensure uninterrupted operation, we recommend that

the gas supply system be fed from two gas cylinders, with

an automatic switchover device. The specified fuel is

propane and the supply pressure must be 11 inches

(280mm) water column. The Refrigerator must be

connected with copper or other acceptable tubing of

sufficient diameter to avoid a pressure drop of more than

one inch (25 mm) water gauge up to the Refrigerator inlet,

even with other gas-operated appliances (such as water

heaters, and stoves) operating from the same system.

•

The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3,5 kPa).

•

The appliance must be isolated from the gas supply

piping system by closing its individual manual shut off

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2

psig (3.5 kPa).

To install the Refrigerator:

•

If necessary, install a metal or wood panel over the floor

as recommended in item 2.1. (b).

•

Disassemble the burner box (C8).

•

Place the Refrigerator in its definite position. Turn the

bolts until the Refrigerator is level. Remove it again from

its location.

•

Connect the gas supply to the manual shut off valve

(C12). Use a certified flexible type metal connector of

sufficient length.

•

Connect a pressure gauge at the plug (F5) ot the

controls.

Now check the operation:

•

Operate the Refrigerator according to the instructions

(E6) and allow it to work for at least 30 minutes.

•

During this period, check the connections for leaks, from

the gas inlet to the orifice spud, using a detergent and

water solution.

•

Check the reading of the pressure gauge. With no other

gas appliance operating it should not pass 11” water

gauge. With other appliances operating it should not fall

below 10”.

•

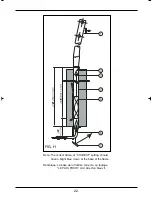

With a mirror (H7) beneath the flame tube (H4), make

sure that the flame color is blue. It should not reach the

tip of the baffle (H5), which will normally be slightly

aglow.

•

Turn off the gas at the control (B3) leaving the manual

shut off valve (C12) open. Replace the plug (F5).

•

Replace the burner box (C8).

Summary of Contents for UGP 7.8

Page 2: ......

Page 12: ...19 6 1 5 2 3 4 FIG A FIG B FIG C ...

Page 13: ...20 FIG D FIG G FIG F ...

Page 14: ...21 Cut out in order accommodate the lower hinge A découper pour la charnière inférieure FIG E ...

Page 16: ...24 ...