2

2

2-2. Operation

1) Overview

➔

Different operation processes are applied to Sensor Dry Course and Manual Dry Course.

➔

Sensor Dry Course judges the condition of laundry with humidity/temperature sensors so as to decide

appropriate dry level.

➔

Manual Dry Course dries laundry as per temperature conditions set by an operator.

2) Process of Sensor Dry Course

A. Power Button On

➔

“_ _ _” is displayed at 18:88 LED.

➔

Press Start Button to automatically select Normal Course.

➔

“Check Filter” of Custom LED goes on and off before you press Start Button.

➔

“High” of initial Beeper goes on and the previous Beeper value is displayed when you switch on the

power.

B. Operation Selection

➔

Select operation with Course Switch/Button.

➔

“Check Filter” of Custom LED goes on and off before you press Start Button. Once the unit starts

operating, “Check Filter” goes off.

➔

Buttons operate as per 2-1.

➔

The selected Course/Dry Level/Temp Control/Time Dry/Beeper goes on and Custom LED displays

Dry/Cooling.

➔

Option LED may go on and off according to your selection.

합본 svc manual 2008.5.6 6:21 PM 페이지24

Summary of Contents for KUD-WG33S

Page 1: ...JUL 2008 Service Manual Model KUD WG33S Gas Dryer ...

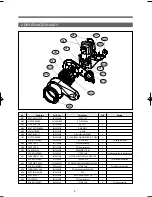

Page 8: ...1 DRYER CBINET ASS Y PartsListbyAss y 7 ...

Page 35: ...33 2 DIAGRAMA SECADORA DE GAS ...

Page 58: ...57 BLOCK DE TERMINALES 1 Remove cover terminal 2 Remove 3 screws sólo secadora eléctrica ...

Page 63: ...4 Switch de Puerta Presione los seguros y empuje hacia el frente ...