19

When using this on LPG gas, conversion must be made by a qualified LPG install-

er before attempting to operate the range on that gas.

For correct operation, the pressure of natural gas supplied to the regulator should

be between 4” and 5” of water column. For LP gas, the pressure supplied must be

between 10” and 12” of water column.

When checking for correct operation of the regulator, the inlet pressure must be at

least 1” more than the operating -manifold- pressure as given above. The pressure

regulator located at the back of the range manifold must remain in the supply line

regardless of whether natural or LP gas is being used.

Regulator is only good for psi (14” w.c.) so test pressure must not exceed

1

/

2

” psi.

Shut off the main gas supply valve before removing the old range and leave it off

until the new hook-up has been completed.

Because hard piping restricts movement of the range, the use of a CSA/ETL cer-

tified flexible metal appliance connector is recommended unless local codes re-

quire a hardpiped connection. Never reuse an old connector when installing a new

range. If the hard piping method is used, you must carefully align the pipe; the

range cannot be moved after the connection is made.

To prevent gas leaks, use pipe joint compound resistant to LP or NG gases (de-

pending on set up) on all male -external- pipe threads.

1. In an easily accessible location, install a service manual gas shut off valve. Be

sure everyone operating the range knows where and how to shut off the gas

supply to the range.

2. When all connections have been made, be sure all range controls are in the off

position and turn on the main gas supply valve. Check for gas leaks by using a

soap and water solution. If a gas leak is present, shut off gas immediately, tight-

en all connections, and retest for leaks.

3. Any opening in the wall behind the appliance and in the floor under the appli-

ance must be sealed.

After installation:

1. Check ignition of cooktop burners.

2. Check ignition of oven burner.

3. Check ignition of broiler burner.

4. Check for gas leaks at all gas connections (using a gas detector, never a flame)

GAS CONNECTIONS (All Units)

Summary of Contents for Classic Plus

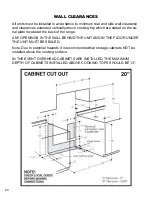

Page 21: ...21 WALL CLEARANCES continued 24 ...

Page 22: ...WALL CLEARANCES continued 22 ...

Page 49: ...20 PARTS DIAGRAM AND LIST 49 ...

Page 52: ...52 24 PARTS DIAGRAM AND LIST ...

Page 56: ...NOTES 56 ...