51

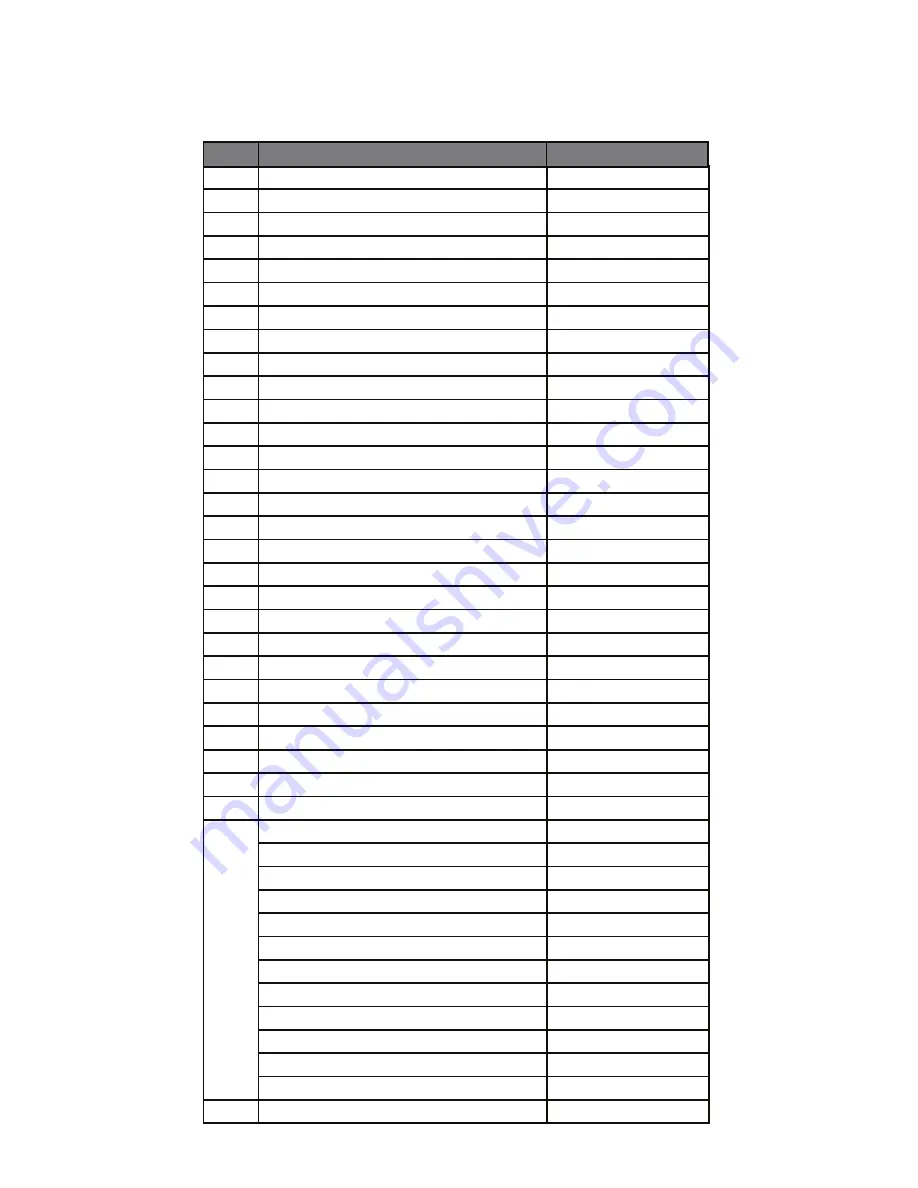

PARTS LIST

68

Oven rack

UGP-G20H08-071900

69

Broil tray

UGP-G20C01-215000

70

Broil grill

UGP-G20C01-215100

71

Back plate

UGP-G20C01-070303

72

(2.5Kg) Weight Block

UGP-UGP-G20A01-210200

73

Regulator fixed part

UGP-G20C01-034500

74

120V Ignitor

UGP-G20C01-170106

75

Power fixed parts

UGP-G20A01-160200

76

Power Cord

UGP-G20A07-160105

77

Cavity left plate

UGP-G20A01-070400

78

0.5 Side plate S/S

UGP-G20C01-071002

78

0.5 White

UGP-G20C01-071002-01

78

0.5 Black

UGP-G20C01-071002-02

79

120V Temperature fan

UGP-G20A01-091501

80

Back insulation cotton

UGP-G20C01-072900

81

Temperature fan baffle

UGP-C36A01-073100

82

Baffle plate

UGP-G20C01-072000

83

Cooktop back connection plate

UGP-G20C01-022000

84

Support between wall and unit

UGP-G20C01-212600

85

120V 15W Oven lamp

UGP-G20C01-180101

86

Top burner assembly

UGP-G20C01-090100

87

Top burner plate

UGP-G20C01-090300

88

Top burner infrared network

UGP-G20C01-090500

89

Grill burner spark plug 540

UGP-G20C01-170500

90

Cavity top plate

UGP-G20C01-070601

91

Chimney

(

with hole

)

UGP-G20C01-074101

92

Chimney

(

no hole

)

UGP-G20C01-074100

93

Diversion Plate

UGP-G20C01-075000

NG Injector(0.73)

UGP-G20A01-021208

LPG Injector(0.53)

UGP-G20A01-021200

NG Injector (1.0)

UGP-G20A01-021206

LPG Injector(0.68)

UGP-G20A01-021201

NG Injector(1.3)

UGP-G20A01-021213

LPG Injector(0.9)

UGP-G20A01-021203

NG Injector(1.5)

UGP-G20A01-021227

LPG Injector(1.0)

UGP-G20A01-021206

Top burner NG injector

(

1.24

)

UGP-G20A01-021212

Top burner LPG injector

(

0.8

)

UGP-G20A01-021202

Oven burner NG injector

(

1.3

)

UGP-G20A01-021213

Oven burner LPG injector(0.82)

UGP-G20A01-021204

95

Nozzle mount part

UGP-G20A01-021100

94

Item #

Description

Part #

1

Backsplash

UGP-G20H08-011600

2

Backsplash inner plate

UGP-G20H08-011700

3

Backsplash cover

UGP-G20H08-011500

4

75 burner

UGP-G20A02-040100

5

130 burner

UGP-G20A02-040300

6

100 burner

UGP-G20A02-040200

7

55 burner

UGP-G20A02-040000

8

Grates

(

left

)

UGP-G20H08-021300

9

Grates

(

right

)

UGP-G24C05-021600

10

Cooktop

UGP-G20H08-020100

11

Cavity heat insulation plate

UGP-C20B01-074500

12

Regulator adaptor

UGP-G24G02-034200

13

NG5" LPG10" Regulator

UGP-G20C01-034002

14

Regulator support

UGP-G24G02-034500

15

Gas pipe

UGP-G20H08-030700

16

Thermostat

UGP-G20C02-030619

17

Valve-0.50

UGP-G20D02-030535

18

Valve-0.81

UGP-G20D02-030533

19

Valve-0.95

UGP-G20D02-030534

20

Control panel inside panel

UGP-G20H08-030400

21

Control panel insulation cotton

UGP-G20H08-036000

22

Control panel S/S

UGP-G20H08-030300

22

Control panel white

UGP-G20H08-030300-01

22

Control panel black

UGP-G20H08-030300-02

23

Control panel connection plate

(

right

)

UGP-G20C01-022200

24

Switch ASM

UGP-G24H08-170200

25

Knob 19#

UGP-G20A19-030100-09

25

Knob #19 white

UGP-G20A19-030100-01

26

Knob ring (bezel)

UGP-G20A06-030200-10

28

Control panel strip

UGP-G20H08-214500

29

Control panel connection plate

(

left

)

UGP-G20C01-022100

30

G1/2 gasket

UGP-G20A01-210500

31

Door top cover

UGP-G20B01-101401

32

Door glass shockproof

UGP-G20A01-103300

33

LOWE Inner glass door

UGP-G20H08-100500

34

LOWE Door inside window

UGP-G20H08-101100

35

Hinge Support(right)

UGP-G20B01-101300

36

Door frame

(

up) S/S

UGP-G20H08-020000

36

Door frame

(

up) white

UGP-G20H08-020000-01

36

Door frame

(

up) black

UGP-G20H08-020000-02

Summary of Contents for UGP-20V PC1 S/S

Page 21: ...21 WALL CLEARANCES continued ...

Page 46: ...UGP 20V PC1 S S WIRING DIAGRAM 46 ...

Page 54: ...NOTES 54 ...