U N I Q U E U G P - 2 2

24

Step B: Alarm Activation Step C: Removal and Installation

6.3

To insure aesthetic alignment of the alarm with the hallway or wall, the

UP arrow on the mounting plate must be vertical when wall mounting:

(See Step A in Figure 2)

6.4 As described in Figure 2, attach the mounting plate on the wall. Use the

screws and anchors provided to secure the mounting plate.

6.5

The battery is INSTALLED REVERSED FOR SHIPPING. Remove and

reinstall the battery in the correct orientation as noted on the inside of

the battery door. When installing the battery, align the “+” and “-“

battery terminals on the correct contacts. The alarm will beep once

indicating proper battery installation.

WARNING

: Battery is required for operation of appliance, alarm

operation and detection of carbon monoxide. If no battery is installed,

the appliance will not stay lit. The battery door will not close easily and

the unit will not attach to the mounting bracket.

6.6 Twist the alarm in the direction indicated by the “ON” arrow on the

alarm cover (see step D) until it locks in place.

6.7 To make your carbon monoxide alarm tamper resistant, a locking pin has

been provided in the bag with the screws and anchors. Using this pin

will deter children and others from removing the alarm from the

mounting plate. To use the pin insert it into the hole in the side of the

alarm after the alarm has been installed on the mounting plate (See

Figure 3). Note the tamper resist pin will have to be removed in order to

Figure 2: Installation Instructions

Summary of Contents for UGP 22

Page 1: ...625 8 L 22 1 cu ft UGP 22 Propane Refrigerator OWNER S GUIDE serial number March 2016 ...

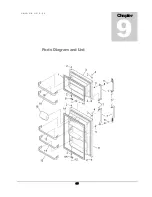

Page 39: ...U N I Q U E U G P 2 2 35 Parts Diagram and List Chapter 9 ...

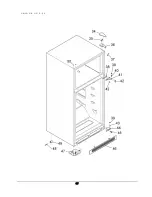

Page 40: ...U N I Q U E U G P 2 2 36 ...

Page 41: ...U N I Q U E U G P 2 2 37 ...

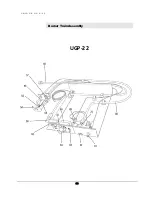

Page 42: ...U N I Q U E U G P 2 2 38 Burner Train Assembly UGP 22 ...