23

10. Take the NG orifices provided and install them as shown below

See below for rating of orifice for each model

11. Once all the orifices are installed, replace all burners and burner caps, then fire up

the burners to check the minimum flame height.

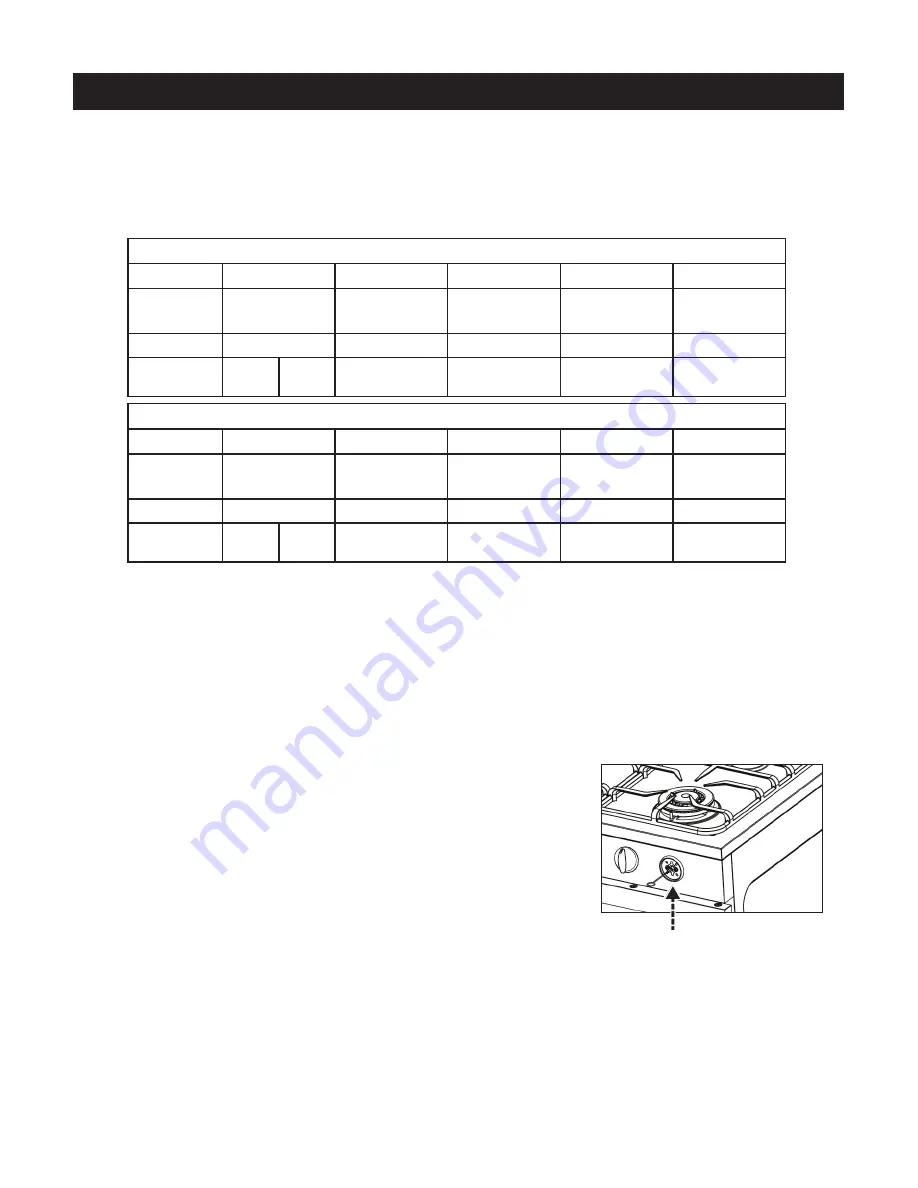

12. Minimum flame height should be approx. 1/4” tall. There is a small adjustment screw

located on the valve itself. The lid and the front control panel must be removed to

accomplish this adjustment.

13. Turn the valve fully counter clockwise. Then proceed

to adjust the adjustment screw clockwise for a smaller

flame and counter clockwise for a larger flame.

Adjustment: Minimum flame should be approx. 1/4”

tall.

14. Temporarily replace the lid, burners, burner caps

and grates and recheck the flame. Once complete,

reassemble the control panel and the lid.

15. Next, the oven orifice needs to be replaced.

16. Remove all racks, then the bottom pan by lifting up the back first to release the front

then pull pan out.

17. Locate the burner tube and locate the retaining screw at the front of the tube. Once

this screw has been removed, lift up the burner and pull away slightly to the right to

expose the oven orifice.

GAS RANGE CONVERSION (continued)

FLAME HEIGHT ADJUSTMENT

Adjustment location is

inside the valve stem

Adjustment location is inside the

valve stem

Natural Gas Orifices

BTU

13,000

10,000

3,200

10,000

13,000

BURNER

Triple Burner Semi-Rapid

Burner

Simmer

Burner

Rapid Burner Oven Burner

POSITION

Front Right

Rear Left

Rear Right

Front Left

ORIFICE

0.68

1.28

x2

1.50

0.90

1.50

1.9

Liquid Propane Gas Orifices

BTU

14,000

9,000

3,200

9,000

13,500

BURNER

Triple Burner Semi-Rapid

Burner

Simmer

Burner

Rapid Burner Oven Burner

POSITION

Front Right

Rear Left

Rear Right

Front Left

ORIFICE

0.53

0.77

x2

0.93

0.57

0.93

1.12