Page

11

Installation Manual 801.1

SunFrame™ Code-Compliant Planning and Assembly

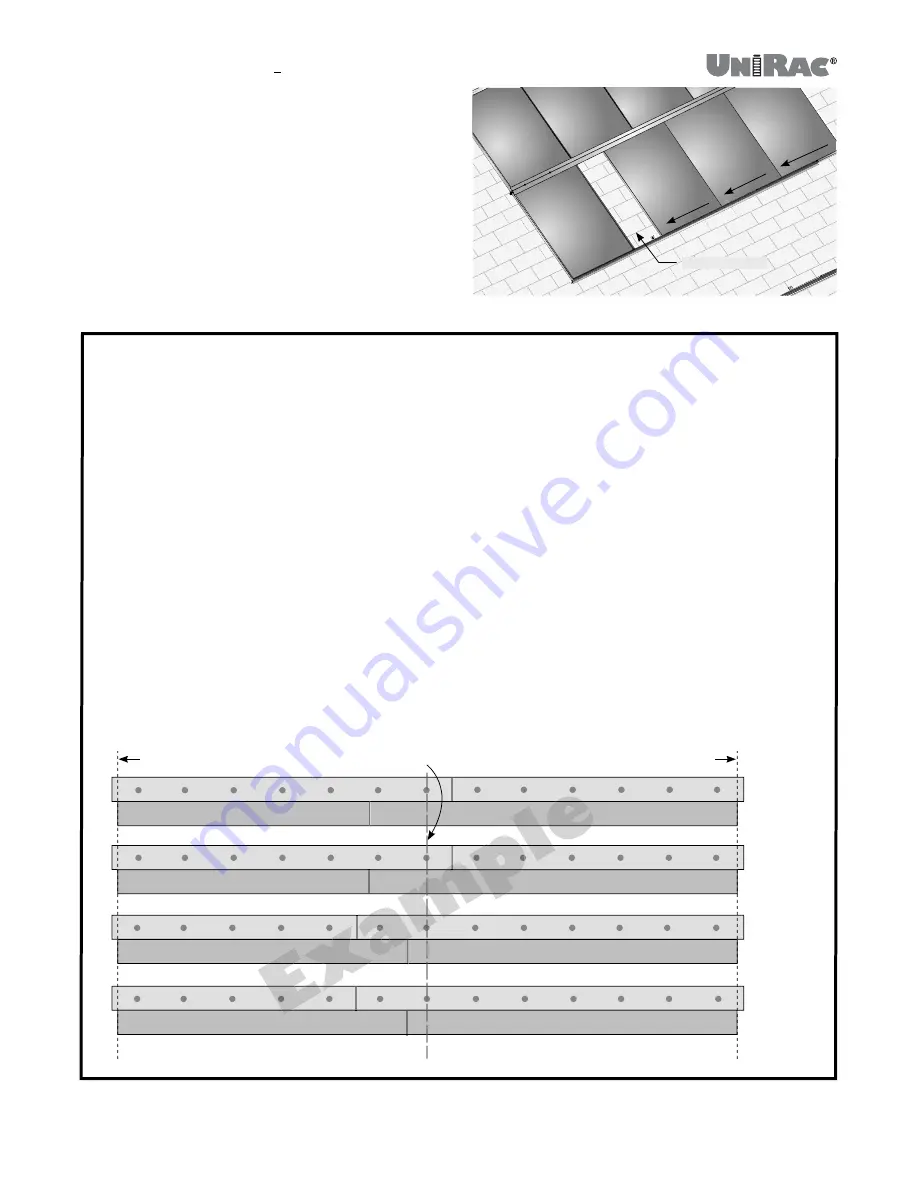

Material planning for rails and cap strips

Typically, 192-inch standard rail and cap strip lengths will

not match the size of your array.

Preplanning material use

for your particular array can prevent structural or asthetic

problems, particularly those caused by very short lengths of rail

or cap strip.

Stuctural requirements for rails are detailed in “Footing and

splicing requirement” (p. 9). Structurally, cap strips require:

• A screw in every prepunched hole (which occur ev-

ery 16 inches, beginning 8 inches from the ends of

the rails). If it is ever necessary to make a new hole

in a cap strip, drill a 1/4-inch hole before installing

the self-drilling screw.

• One screw no more than 8 inches from the end of

each segment.

For maximum asthetic appeal:

• Cap strip screws on every rail should align (see, for

example, the center line holes in the illustration

below).

• End screws should be equidistant from both sides of

the array.

The example below assumes an array of three rows, each

holding fi ve modules 41 inches wide. Thus, four 205-inch

rail–cap strip assemblies need to be cut and spliced from

192-inch sections of rail and cap strip. The example illus-

trates one means of doing so, which meets all structural and

aesthetic requirements while conserving material.

Rails segments come from fi ve 192-inch lengths, lettered A

thru E. Rail A, for example, is cut into two 96-inch segments,

with one segment spliced into each of the fi rst two rails.

Similarly, fi ve 192-inch cap strips are numbered V through Z.

All cap strip segments are cut at the midpoint between

prepunched screw holes. For each rail, start with the cap

strip segment that crosses the array center line, and align the

appropriate hole with the center line.

Position each cap strip onto its rail and mark its trim point.

Remove and trim before fi nal mounting.

Code compliance note: If your planning sketch shows

that end holes will be more than 8 inches from the ends

of the rails, re-start by aligning a

midpoint between holes

with the array center line.

A 96

″

B 109

″

A 96

″

B 83

″

C 83

″

C 109

″

D 122

″

E 122

″

Array center line

V 112

″

W 112

″

W 80

″

V 80

″

X 96

″

Y 128

″

X 96

″

Z 128

″

Usable remainder: D, 70

″

; E, 70

″

; Y, 64

″

; Z, 64

″

.

4th cap strip

1st rail

3rd cap strip

2nd rail

2nd cap strip

3rd rail

1st cap strip

4th rail

Trim line (array edge)

Trim line (array edge)

Continue the process until all modules in the top row are in

fi nal place and secured from the top. When complete, every

prepunched hole in the cap strip will be secured by a screw,

and the top end of the fi rst row of modules will be secure.

8. Installing the remaining modules row by row

Repeat Steps 6 and 7 for the remaing rows (Fig. 11). Each

subsequent cap strip will secure the tops to the modules being

installed and the bottoms of the modules in the row above.

Place the fi nal cap strip in the lowest rail, securing the bottom

of the lowest module row.

Figure 11. As modules slide into place, the stepping gap shifts,

always allowing access to the section of cap strip being secured.

Secured

1st module

Slide and

secure one

by one

Stepping gap