output

November 19, 2019

13:11

Page 11

SulfiLogger_Manual_EN_203.pdf

M

EC

H

A

N

IC

A

L

IN

ST

A

LL

A

T

IO

N

The

Sul

fiL

ogger

™

sensor

can

be

installed

in

four

different

wa

ys:

a)

Free

hanging

(liquids)

b)

Fix

ed

(liquids)

c)

Inline

(gases)

d)

Fix

ed

(gases)

FL

OW

a)

b)

c)

d)

x

x

a)

Free

hanging

(liquids)

This

mounting

option

is

ideal

for

low

flow

reserv

oirs

and

channels

and

gener

ally

suit-

able

for

short

measurement

campaigns.

The

Sul

fiL

ogger

™

sensor

is

installed

at

the

end

of

an

extension

pipe,

attached

to

an

an-

chor

point

using

a

steel

wire

and

suspended

down

into

the

sewage.

The

extension

pipe

ensures

that

the

cables

and

connectors

are

protected

from

fouling.

To

perform

this

installation,

you

must

ensure:

•

That

the

circulation

in

the

reserv

oir

is

suf-

ficient

to

ensure

good

mixing.

•

That

the

sensor

tip

can

not

touch

the

walls

and

bottom

of

the

reserv

oir

,espe-

cially

during

high

flows.

If

there

is

a

risk

of

the

sensor

hitting

the

walls,

then

you

should

perform

the

"fi

xed

(liquids)"

instal-

lation

instead.

•

That

you

ha

ve

a

suitable

anchor

point

available

to

attach

the

steel

wire

to.

•

That

the

length

of

the

steel

wire

allows

the

sens

or

to

remain

in

the

liquid

at

all

times

while

the

back

of

the

extension

pipe

at

the

same

time

remains

out

of

the

liquid.

b)

Fix

ed

(liquids)

This

mounting

option

is

ideal

for

permanent

installations

in

low

and

high

flow

reserv

oirs

and

channels.

It

is

similar

to

the

"F

ree

hang-

ing

(liquids)"

installation

in

most

regards

but

here,

the

extension

pipe

(and

sensor)

is

fixated

-

not

hanging

in

the

steel

wire.

Unisense

does

not

supply

br

ack

ets

or

an

y

other

materials

for

this

installation

method.

c)

Inline

(gases)

Directly

on

the

main

pipe

The

Sul

fiL

ogger

™

sensor

can

be

installed

on

a

pipe

stub

allowing

measurement

in

a

closed

system.

•

Before

installing

the

pipe

stub

a

30

mm

hole

must

be

drilled

in

the

main

pipe.

•

The

pipe

stub

is

supplied

by

Unisense

and

must

be

welded

onto

the

main

pipe.

•

Use

a

spanner

(size

36)

to

screw

the

Sul-

fiL

ogger™

sensor

onto

the

pipe

stub.

•

Beware

of

the

pressure

rating

of

the

Sul-

fiL

ogger

™

sensor

and

ensure

that

the

pressure

pipe

system

does

not

ex

ceed

the

pressure

limit.

Bypass

flow

using

a

flow

cell

A

portion

of

the

flow

can

be

di-

rected/b

ypassed

into

a

flow

cell

on

which

the

Sul

fiL

ogger™

sensor

is

installed.

•

Before

the

installation,

please

ensure

that

the

pressure

and

temper

ature

rat-

ings

of

the

bypassed

flow

are

within

the

speci

fications

of

the

Sul

fiL

ogger

™

sensor

.

•

The

flow

cell

is

supplied

by

Unisense.

•

Use

a

spanner

(size

36)

to

screw

the

Sul-

fiL

ogger™

sensor

onto

the

flow

cell.

d)

Fix

ed

(gases)

The

Sul

fiL

ogger

™

sensor

can

be

mounted

in

pump

wells,

reserv

oirs

etc.

abo

ve

wa-

ter

le

vel

for

gas

phase

measurements.

The

outer

diameter

of

the

Sul

fiL

ogger

™

sen-

sor

resembles

a

1.5

"pipe

and

can

thus

be

mounted

using

a

standard

1.5

"pipe

ring.

Extension

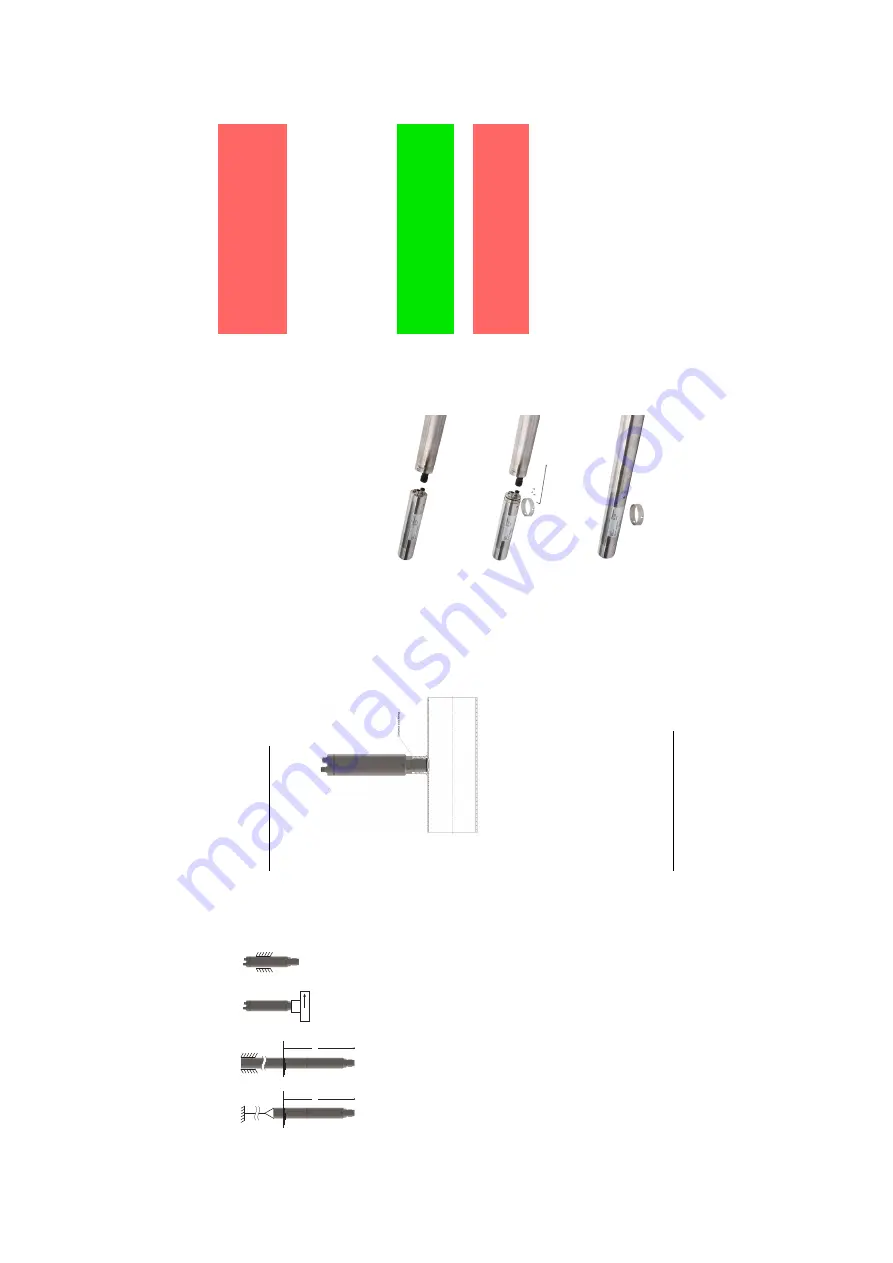

pipe

installation

For

free

hanging

and

fix

ed

measurements

in

liquids,

an

extension

pipe

must

be

at-

tached

to

the

Sul

fiL

ogger

™

sensor

.This

fig-

ure

shows

the

steps

needed

to

perform

this

installation:

•

Unscrew

the

three

he

x

screws

on

the

back

of

the

Sul

fiL

ogger

™

sensor

and

re-

mo

ve

the

outer

ring.

•

Feed

the

cables

through

the

extension

pipe

and

attach

them

to

the

connectors

on

the

sensor

.

•

Align

the

sensor

with

the

screw

holes

of

the

extension

pipe

and

screw

in

the

three

he

x

screws

to

secure

the

sensor

to

the

extension

pipe.

Temper

ature

rating

The

sensor

is

designed

to

withstand

temper-

atures

from

-20

◦

C

to

+60

◦

C.

D

ANGER

Exposing

a

Sul

fiL

ogger

™

sensor

from

the

X1-series

for

ambient

temper

a-

tures

lower

than

-20

◦

C

or

higher

than

+60

◦

C

will

void

the

ATEX

certi

ficate.

The

sensor

,both

S1

and

X1

series,

performs

optimally

between

0

◦

C

and

+40

◦

C.

Disassembly

W

e

do

not

recommend

you

to

disassemble

the

Sul

fiL

ogger™sensor.

IMPOR

TANT

NO

TE

Disassembly

of

the

sensor

will

void

the

warr

anty

and

render

the

sensor

non-

functional.

D

ANGER

Disassembly

of

a

Sul

fiL

ogger

™

sensor

from

the

X1-series

will

void

the

ATEX

certi

ficate.

S

U

P

P

O

R

T

Unisense

A/S

Tueager

1

DK

-8200

Aarhus

N

Denmark

E-mail:

Sul

fiL

ogger@unisense.com

Tel:

+45

8944

9500

Fax:

+45

8944

9549

For

further

documentation,

the

latest

User

Manual

and

other

resources,

please

visit

the

Sul

fiL

ogger™

sensor

website:

www

.Sul

fiL

ogger

.com

11