290982-UIM-C-0907

2

Unitary Products Group

SECTION III: UNIT INSTALLATION

LOCATION

Before starting the installation, select and check the suitability of the

location for both the indoor and outdoor unit. Observe all limitations and

clearance requirements.

The outdoor unit must have sufficient clearance for air entrance to the

condenser coil, air discharge, and service access. See Figure 1.

NOTE:

For multiple unit installations, units must be spaced a minimum

of 18 inches apart (coil face to coil face).

If the unit is to be installed on a hot sun exposed roof or a black-topped

ground area, the unit should be raised sufficiently above the roof or

ground to avoid taking the accumulated layer of hot air into the outdoor

unit.

Provide an adequate structural support.

ADD-ON REPLACEMENT/RETROFIT

The following steps should be performed in order to insure proper sys-

tem operation and performance.

1.

Change-out the indoor coil, if required, to an approved R-22 coil/

condensing unit combination with the appropriate metering device.

2.

If the outdoor unit is being replaced due to a compressor burnout,

then installation of a 100% activated alumina suction-line filter

drier in the suction-line is required, in addition to the factory

installed liquid-line drier. Operate the system for 10 hours. Monitor

the suction drier pressure drop. If the pressure drop exceeds 3

psig, replace both the suction-line and liquid-line driers. After a

total of 10 hours run time where the suction-line pressure drop has

not exceeded 3 psig, replace the liquid line drier, and remove the

suction-line drier. Never leave a suction-line drier in the system

longer than 50 hours of run time.

GROUND INSTALLATION

The unit should be installed on a solid base that is 2” above grade and

will not shift or settle, causing strain on the refrigerant lines and possible

leaks. Maintain the clearances shown in Figure 1 and install the unit in a

level position. The base pad should not come in contact with the foun-

dation or side of the structure because sound may be transmitted to the

residence.

The length of the refrigerant tubing between the outdoor unit and indoor

coil should be as short as possible to avoid capacity and efficiency

losses. Excessive spacing of the outdoor unit from the home can result

in the refrigerant lines being restricted by trampling or being punctured

by lawn mowers. Locate the outdoor unit away from bedroom windows

or other rooms where sound might be objectionable.

Adverse effects of snow or sleet accumulating on the outdoor coil can

be eliminated by placing the outdoor unit where the prevailing wind

does not blow across the unit. Trees, shrubs, corners of buildings, and

fences standing off from the coil can reduce capacity loss due to wind

chill effect.

Provide ample clearance from shrubs to allow adequate air to pass

across the outdoor coil without leaves or branches being pulled into the

coil.

ROOF INSTALLATION

When installing units on a roof, the structure must be capable of sup-

porting the total weight of the unit, including a pad, lintels, rails, etc.,

which should be used to minimize the transmission of sound or vibra-

tion into the conditioned space.

LIQUID LINE FILTER-DRIER

The air conditioning unit’s copper spun filter/dryer is located on the liq-

uid line.

NOTE: Replacements for the liquid line drier must be exactly the same

as marked on the original factory drier. See

Source 1 for O.E.M.

replacement driers.

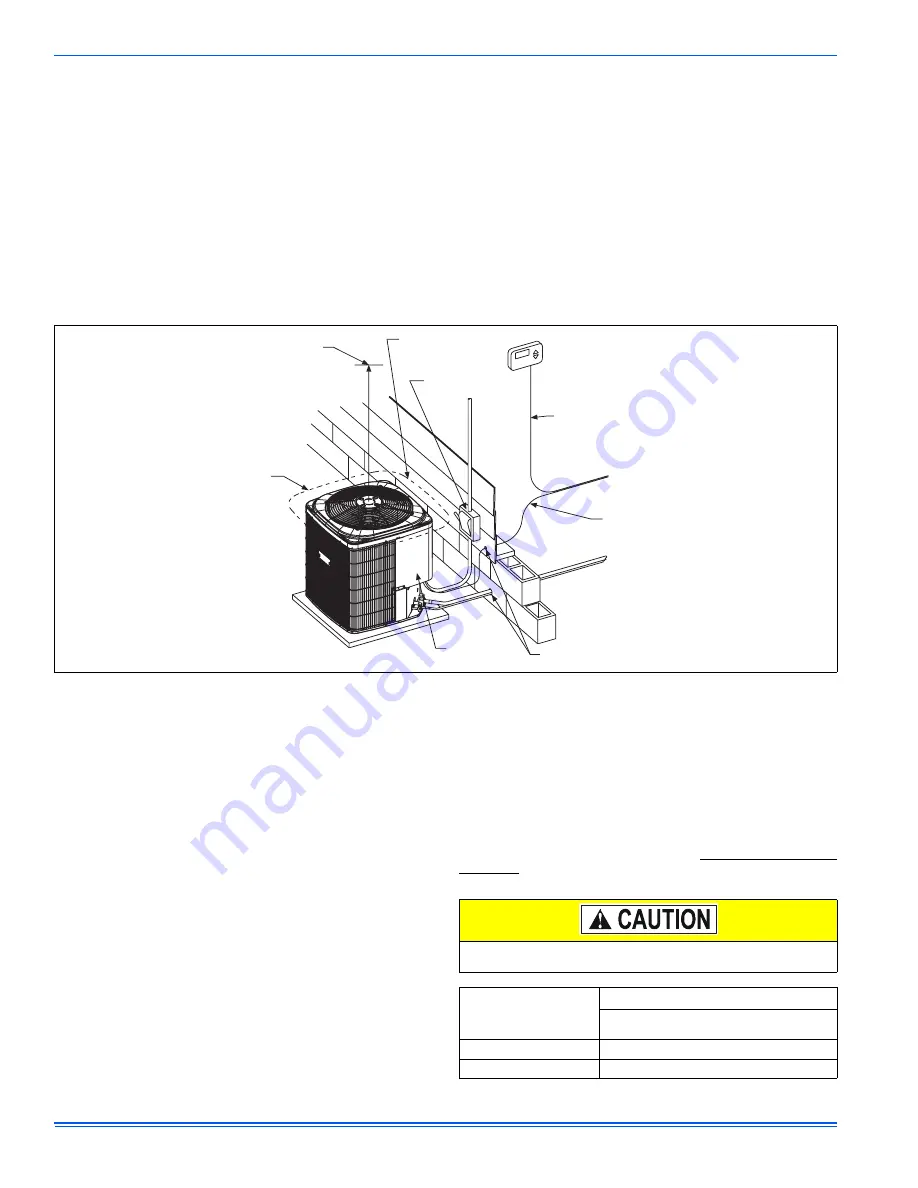

FIGURE 1:

Typical Installation

THERMOSTAT

SEAL OPENING(S) WITH

PERMAGUM OR EQUIVALENT

TO INDOOR COIL

TO FURNACE OR

AIR HANDLER

TERMINAL BLOCK

NEC CLASS 2 WIRING

NEC CLASS 1 WIRING

ALL OUTDOOR WIRING

MUST BE WEATHERPROOF.

CONTROL

ACCESS

PANEL

WEATHERPROOF

DISCONNECT

SWITCH

MINIMUM 18” SERVICE

ACCESS CLEARANCE

ON ONE SIDE

60” OVERHEAD

CLEARANCE

6” CLEARANCE

AROUND PERIMETER

NOTE:

Failure to do so or using a substitute drier or a granular type may

result in damage to the equipment.

R-22

Filter-Drier

Source 1 Part No.

Apply with Models

TCGD / GCGD

S1-02922156000

1 to 3 Tons

S1-02922157000

3.5 to 5 Tons