290982-UIM-C-0907

6

Unitary Products Group

SUBCOOLING CHARGING METHOD - TXV INDOOR

The recommended subcooling is 10°F

1.

Set the system running in the cooling mode by setting the thermo-

stat at least 6°F below the room temperature.

2.

Operate the system for a minimum of 15-20 minutes.

3.

Refer to the tabular data sheet for the recommended airflow and

verify this indoor airflow (it should be about 400 SCFM per ton).

4.

Measure the liquid refrigerant pressure P and temperature T at the

service valve.

5.

Calculate the saturated liquid temperature ST from Table 2.

6.

Subcooling temperature TC = Saturated Temperature (ST) - Liquid

Temp (T).

Add charge if the calculated subcooling temperature TC in Step 6 is

lower than the recommended level. Remove and recover the refrigerant

if the subcooling TC is higher than the recommended level. See Table

2.

Check flare caps on service ports to be sure they are leak tight. DO

NOT OVERTIGHTEN (between 40 and 60 inch - lbs. maximum).

SECTION VIII: ELECTRICAL

CONNECTIONS

GENERAL INFORMATION & GROUNDING

Check the electrical supply to be sure that it meets the values specified

on the unit nameplate and wiring label.

Power wiring, control (low voltage) wiring, disconnect switches and over

current protection must be supplied by the installer. Wire size should be

sized per NEC requirements.

The complete connection diagram and schematic wiring label is located

on the inside surface of the unit service access panel.

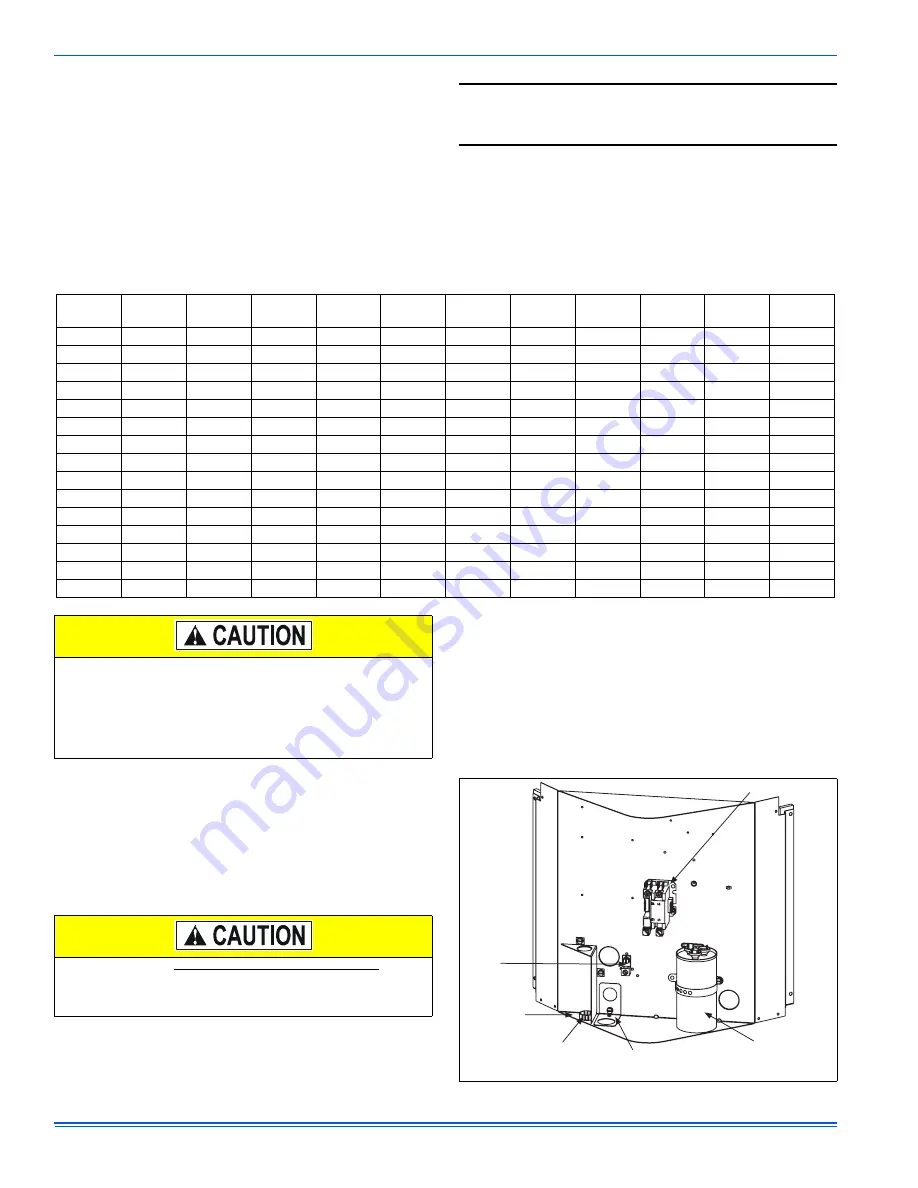

FIELD CONNECTIONS POWER WIRING

1.

Install the proper size weatherproof disconnect switch outdoors

and within sight of the unit.

2.

Remove the screws at the top and sides of the corner cover. Slide

corner cover down and remove from unit.

3.

Run power wiring from the disconnect switch to the unit.

4.

Route wires from disconnect through power wiring opening pro-

vided and into the unit control box as shown in Figure 6.

5.

Install the proper size time-delay fuses or circuit breaker, and

make the power supply connections.

Example: The pressure P and temperature T measured at the liq-

uid service port is 196 psig and 90°F, respectlvely. From Table 2,

the saturated temperature for 196 psig is 100°F. The subcooling

temperature TC = 100°-90°=10°F

TABLE 2:

R-22 Saturated Properties

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

Pressure

PSIG

Temp °F

80

48

110

64

140

78

170

91

200

101

230

111

82

49

112

65

142

79

172

91

202

102

232

112

84

50

114

66

144

80

174

92

204

103

234

112

86

51

116

67

146

81

176

93

206

103

236

113

88

52

118

68

148

82

178

94

208

104

238

114

90

54

120

69

150

83

180

94

210

105

240

114

92

55

122

70

152

84

182

95

212

105

242

115

94

56

124

71

154

84

184

96

214

106

244

115

96

57

126

72

156

85

186

97

216

107

246

116

98

58

128

73

158

86

188

97

218

107

248

117

100

59

130

74

160

87

190

98

220

108

250

117

102

60

132

75

162

88

192

99

222

109

252

118

104

61

134

76

164

88

194

99

224

109

254

118

106

62

136

77

166

89

196

100

226

110

256

119

108

63

138

78

168

90

198

101

228

111

258

119

IT IS UNLAWFUL TO KNOWINGLY VENT, RELEASE OR DIS-

CHARGE REFRIGERANT INTO THE OPEN AIR DURING

REPAIR, SERVICE, MAINTENANCE OR THE FINAL DISPOSAL

OF THIS UNIT.

WHEN THE SYSTEM IS FUNCTIONING PROPERLY AND THE

OWNER HAS BEEN FULLY INSTRUCTED, SECURE THE

OWNER’S APPROVAL.

All field wiring must USE COPPER CONDUCTORS ONLY and be

in accordance with Local, National, Fire, Safety & Electrical Codes.

This unit must be grounded with a separate ground wire in accor-

dance with the above codes.

FIGURE 6:

Outdoor Unit Control Box

GROUND

LUG

“FINGERED”

BUSHING

LOW

VOLTAGE

BOX

REVERSIBLE HIGH

VOLTAGE CONDUIT PLATE

DUAL

RUN/FAN

CAPACITOR

CONTACTOR