271001-UIM-A-0407

Unitary Products Group

7

Horizontal Installations With a Cooling Coil Cabinet

The furnace should be installed with coil cabinet part number specifi-

cally intended for Horizontal application. If a matching cooling coil is

used, it may be placed directly on the furnace outlet and sealed to pre-

vent leakage. Follow the coil instructions for installing the supply ple-

num. For details of the coil cabinet dimensions and installation

requirements, refer to the installation instructions supplied with the coil

cabinet

Attach the supply plenum to the air conditioning coil cabinet outlet duct

flanges through the use of S cleat material when a metal plenum is

used. The use of an approved flexible duct connector is recommended

on all installations. The connection to the furnace, air conditioning coil

cabinet and the supply plenum should be sealed to prevent air leakage.

The sheet metal should be crosshatched to eliminate any popping of

the sheet metal when the indoor fan is energized.

The minimum plenum height is 12” (30.5 cm). If the plenum is shorter

than 12” (30.5 cm) the turbulent air flow may cause the limit controls not

to operate as designed, or the limit controls may not operate at all. Also

the plastic drain pan in the air conditioning coil can overheat and melt.

Refer to the installation instructions supplied with the air conditioning

coil for additional information.

Horizontal Installations Without a Cooling Coil Cabinet

When installing this appliance, the furnace must be installed so as to

create a closed duct system, the supply duct system must be con-

nected to the furnace outlet and the supply duct system must terminate

outside the space containing the furnace. When replacing an existing

furnace, if the existing plenum is not the same size as the new furnace

then the existing plenum must be removed and a new plenum installed

that is the proper size for the new furnace.

Attach the supply plenum to the furnace outlet duct flanges through the

use of S cleat material when a metal plenum is used. The use of an

approved flexible duct connector is recommended on all installations.

This connection should be sealed to prevent air leakage. The sheet

metal should be crosshatched to eliminate any popping of the sheet

metal when the indoor fan is energized. On all installations without a

coil, a removable access panel is recommended in the outlet duct such

that smoke or reflected light would be observable inside the casing to

indicate the presence of leaks in the heat exchanger. This access cover

shall be attached in such a manner as to prevent leaks.

Residential and Modular Home Horizontal Return Plenum

Connections

The return duct system must be connected to the furnace inlet and the

return duct system must terminate outside the space containing the fur-

nace. When replacing an existing furnace, if the existing plenum is not

the same size as the new furnace then the existing plenum must be

removed and a new plenum installed that is the proper size for the new

furnace.

Attach the return plenum to the furnace inlet duct flanges. This is typi-

cally through the use of S cleat material when a metal plenum is used.

The use of an approved flexible duct connector is recommended on all

installations. The connection of the plenum to the furnace and all the

ducts connecting to the plenum must be sealed to prevent air leakage.

The sheet metal should be crosshatched to eliminate any popping of

the sheet metal when the indoor fan is energized.

The duct system is a very important part of the installation. If the duct

system is improperly sized the furnace will not operate properly. The

ducts attached to the furnace must be of sufficient size so that the fur-

nace operates at the specified external static pressure and within the air

temperature rise specified on the nameplate.

Attic installations must meet all minimum clearances to combustibles

and have floor support with required service accessibility.

IMPORTANT:

if an external mounted filter rack is being used see the

instructions provided with that accessory for proper hole cut size.

ATTIC INSTALLATION

This appliance is design certified for line contact when the furnace is

installed in the horizontal left or right position. The line contact is only

permissible between lines that are formed by the intersection of the top

and two sides of the furnace and the building joists, studs or framing.

This line may be in contact with combustible material.

SUSPENDED FURNACE / CRAWL SPACE

INSTALLATION

The furnace can be hung from floor joists or installed on suitable blocks

or pad. Blocks or pad installations shall provide adequate height to

ensure the unit will not be subject to water damage. Units may also be

suspended from rafters or floor joists using rods, pipe angle supports or

straps. Angle supports should be placed at the supply air end and near

the blower deck. Do not support at return air end of unit. All four sus-

pension points must be level to ensure quite furnace operation. When

suspending the furnace use a secure platform constructed of plywood

or other building material secured to the floor joists. Refer to Figure 3

for typical crawl space installation.

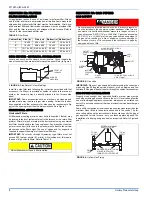

FIGURE 2:

Typical Attic Installation

When a furnace is installed in an attic or other insulated space,

keep all insulating materials at least 12 inches (30.5 cm) away from

furnace and burner combustion air openings.

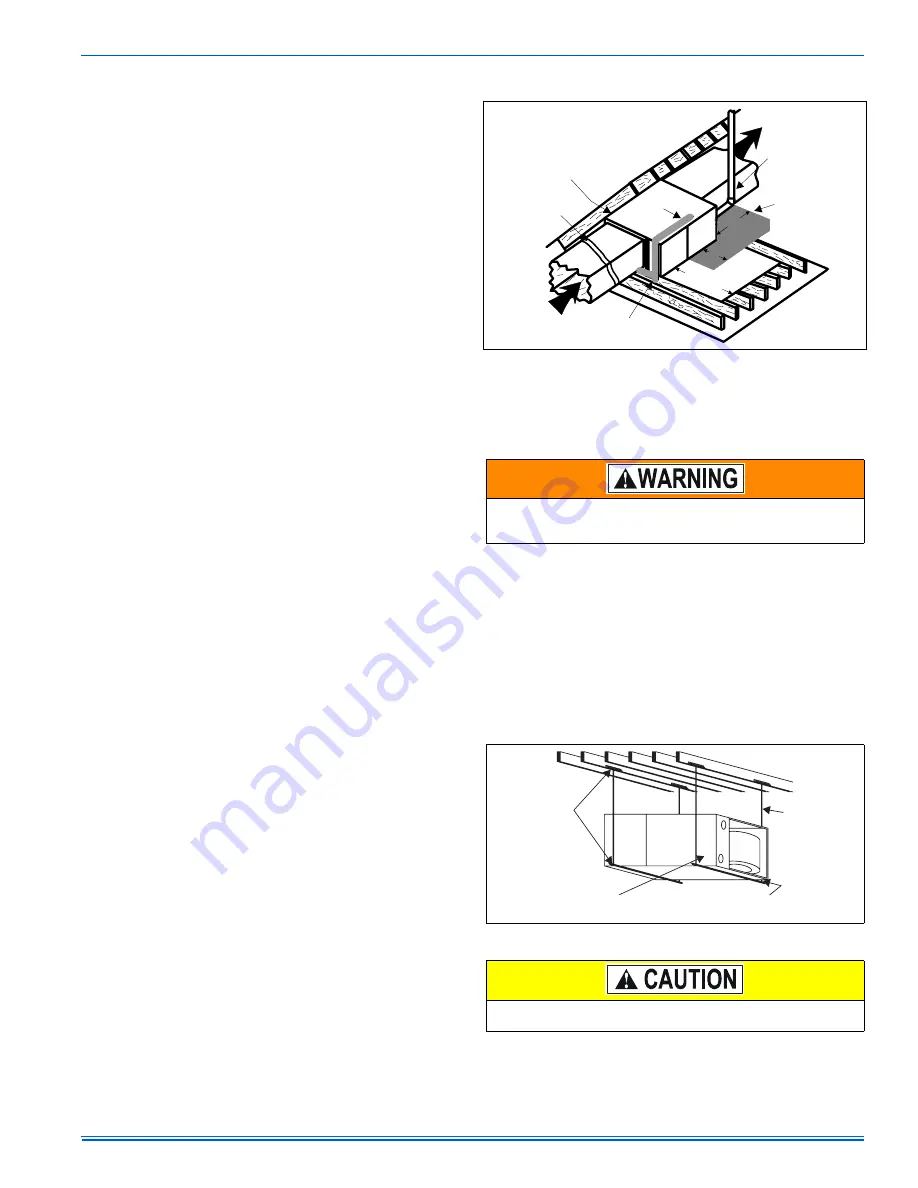

FIGURE 3:

Typical Suspended Furnace / Crawl Space Installation

In any application where temperatures below freezing are possible,

see “INSTALLATION IN FREEZING TEMPERATURES” in Section I

RETURN AIR

SEDIMENT

TRAP

GAS PIPING

SUPPLY AIR

VENT (Maintain

required clearances

to combustibles)

LINE CONTACT ONLY PERMISSIBLE

BETWEEN LINES FORMED BY THE

INTERSECTION OF FURNACE TOP

AND TWO SIDES AND BUILDING

JOISTS, STUDS OR FRAMING

12”

30” MIN.

WORK AREA

FILTER RACK

MUST BE A MINIMUM

DISTANCE

OF 18” (45.7 cm)

FROM THE

FURNACE

12”

SHEET METAL

IN FRONT OF

FURNACE

COMBUSTION AIR

OPENINGS IS

RECOMMENDED

ANGLE IRON

BRACKET

6” MIN. BETWEEN

ROD & FRONT OF FURNACE

1” MAX. BETWEEN

ROD & BACK OF FURNACE

SUPPORT

BRACKET