The thermostat will cycle the electric heat to satisfy the

heating requirements of the conditioned space.

HEAT ANTICIPATOR SETPOINTS

It is important that the anticipator setpoint be correct. Too high

of a setting will result in longer heat cycles and a greater

temperature swing in the conditioned space. Reducing the

value below the correct setpoint will give shorter “ON” cycles

and may result in the lowering of the temperture within the

conditioned space. Refer to Table 12 for the required heat

anticipator setting.

CHECKING SUPPLY AIR CFM

The RPM of the supply air blower will depend on the required

CFM, the unit options/accessories and the static resistances of

both the supply and the return air duct systems. With this

information, the RPM for the supply air blower and the motor

pulley adjustment (turns open) can be determined from the

blower performance data in Tables 5 and 6.

High speed drive accessories (containing a smaller blower

pulley and a shorter belt) are available for applications

requiring the supply air blower to produce higher CFM's and/or

higher static pressures. Use Model 1LD0416 for 15 ton units

and Model 1LD0417 for 20 ton units. Refer to Table 9 for blower

motor and drive data.

Note the following:

1. The supply air CFM must be within the limitations shown in

Table 1.

2. Pulleys can be adjusted in half turn increments.

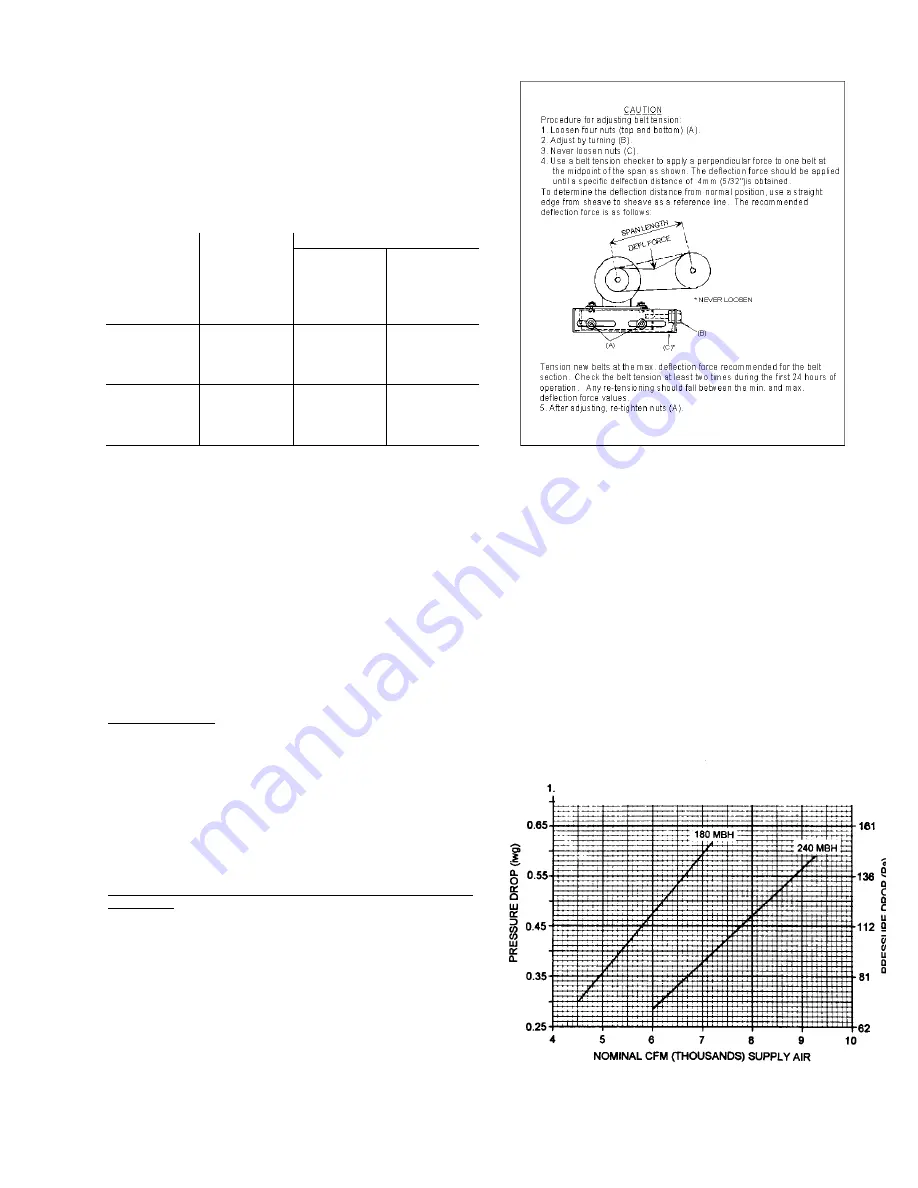

3. The tension on the belt should be adjusted as shown in

Figure 10.

Start the supply air blower motor. Adjust the resistances in both

the supply and the return air duct systems to balance the air

distribution throughout the conditioned space. The job

specifications may require that this balancing be done by

someone other than the equipment installer.

To check the supply air CFM after the initial balancing has been

completed:

1. Remove the two 5/16 inch dot plugs from the blower motor

and the filter access panels shown in Figure 9.

2. Insert at least 8 inches of 1/4 inch tubing into each of these

holes for sufficient penetration into the air flow on both sides

of the indoor coil.

NOTE: The tubes must be inserted and held in a position per-

pendicular to the air flow so that velocity pressure will

not affect the static pressure readings.

3. Using an inclined manometer, determine the pressure drop

across a dry indoor coil. Since the moisture on an indoor

coil may vary greatly, measuring the pressure drop across a

wet coil under field conditions would be inaccurate. To

assure a dry coil, the compressors whould be de-activated

while the test is being run.

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit and clean two-inch filters, can be

determined from the curve in Figure 11.

WARNING: Failure to properly adjust the total system air

quantity can result in extensive blower damage.

After readings have been obtained, remove the tubes and

reinstall the two 5/16 inch dot plugs that were removed in Step

1.

NOTE:

DE-ENERGIZE THE COMPRESSORS BEFORE TAKING

ANY TEST MEASUREMENTS TO ASSURE A DRY IN-

DOOR COIL.

BELT DRIVE BLOWER

All units have belt drive single-speed blower motors. The

variable pitch pulley on the blower motor can be adjusted to

obtain the desired supply air CFM. Tighten belts enough to

Unitary Products Group

15

530.22-N5W

FIG.[f#] - BELT ADJUSTMENT

HEATER

KW

VOLTAGE

SETTING, AMPS

TH1

TH2

18

208/230-3-60

0.29

-

36

0.29

0.29

54

0.29

0.58

72

0.58

0.58

18

460-3-60

0.29

-

36

0.29

0.29

54

0.29

0.29

72

0.29

0.29

18

575-3-60

0.29

-

36

0.29

0.29

54

0.29

0.29

72

0.29

0.29

TABLE 12 - HEAT ANTICIPATOR SETTING

FIG. 9 - PRESSURE DROP ACROSS A DRY INDOOR

COIL VS SUPPLY AIR CFM