12

Unitary Products Group

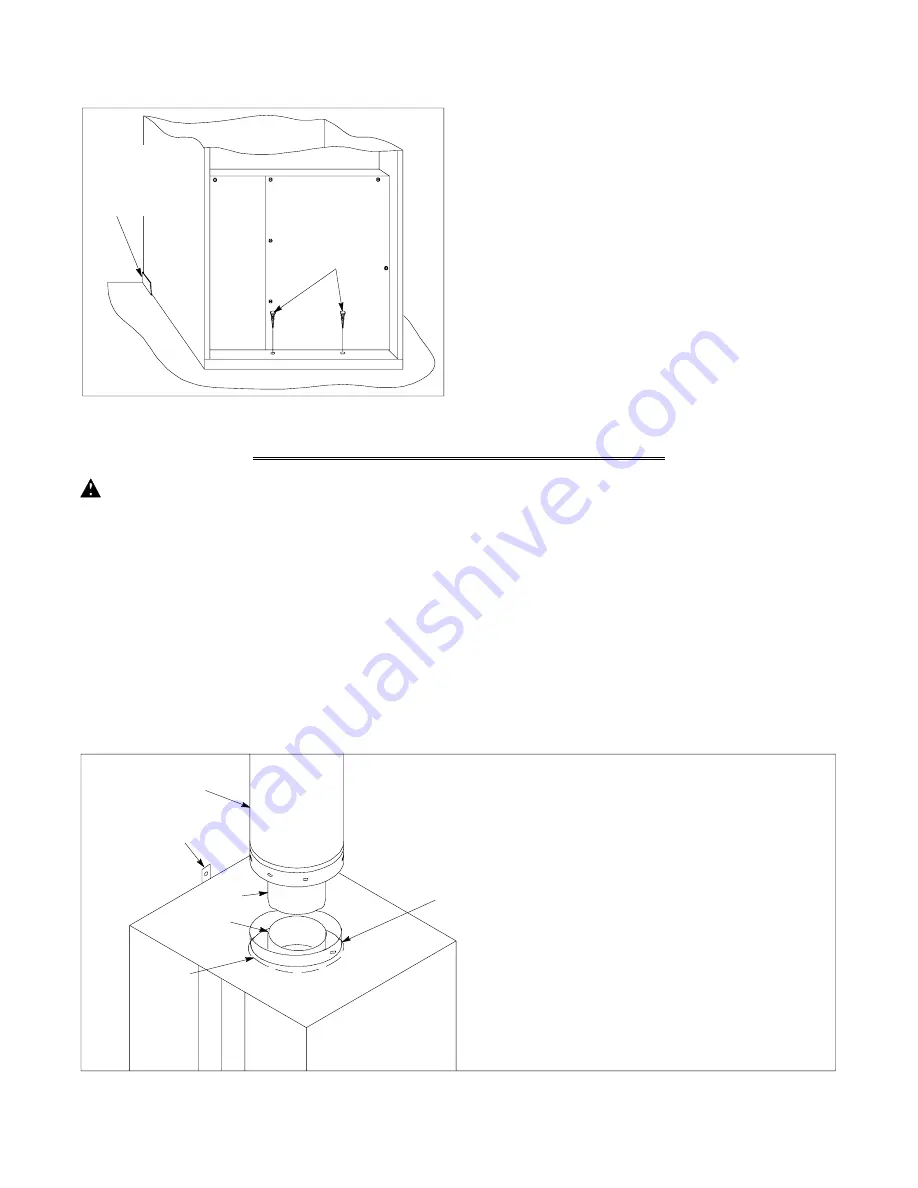

SECURE

FURNACE

TO FLOOR

WITH TWO

NAILS OR

SCREWS

FURNACE

SEATED

AGAINST

THE LOCATOR

BRACKET

FIGURE 11 --

INSTALLATION OF FURNACE

INSTALLATION OF THE FURNACE

1. Remove the front panels and set the furnace onto

the duct connector. Slide it back until the rear of the

unit engages the locator bracket.

2. Secure the front of the furnace with two screws at the

mounting holes provided.

3. Secure the top of the furnace to a structural member

using screw through the strap at the back of the fur-

nace. Strap may be moved to any of the holes lo-

cated along the top back of the furnace. Installer may

provide an equivalent method, such as screws

through the casing side.

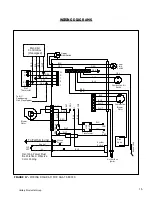

CONNECTING ROOF JACK TO FURNACE

CAUTION:

The inner flue pipe must be present.

It is mandatory that the combustion air pipe and flue

pipe assembly be fully engaged. The combustion air

pipe MUST be securely fastened to the furnace with

a sheet metal screw in the hole provided.

Use a

1

/

2

” blunt or sharp end sheet metal screw to

fasten roof jack combustion air pipe to furnace com-

bustion air collar. Screw hole is provided in the pipe

and collar. Excessively long screws may extend to

flue pipe and puncture it. Screws are not to exceed 1

1

/

2

” in length.

NOTE:

Combustion air tube and flue pipe are part of the

same assembly. Only the combustion air tube

need be fastened to the furnace.

1. Check to be certain that the flue pipe and combus-

tion air tube are present.

2. Pull the telescoping flue tube and combustion air

tube assembly down from the roof jack. Slide the flue

tube/combustion air tube assembly down firmly over

the furnace flue outlet and combustion air collar. In-

sure that the back, side and front of combustion air

tube collar is fully engaged and is in contact with gas-

ket. Fasten the combustion air tube to the furnace

combustion air collar using a

1

/

2

inch sheet metal

screw. (Screw hole provided in combustion air tube

and furnace combustion air collar. (See Figure 12.)

It is mandatory that the combustion air and flue tube assembly

be fully engaged at back sides and front, and combustion air

tube securely fastened to the furnace with a sheet metal screw

in the screw hole provided.

COMBUSTION

AIR TUBE

FLUE

PIPE

COMBUSTION

AIR TUBE COLLAR

#8 OR #10 SCREW RECOMMENDED

FURNACE

FLUE OUTLET

SECURE

STRAP

TO WALL

FRONT OF

FURNACE

FIGURE 12

— CONNECTING ROOF JACK TO FURNACE

GASKET

Summary of Contents for DLAS

Page 23: ...23 Unitary Products Group...