035-18547-001-A-0902

18

Unitary Products Group

10. Is any electrical wire laying against a hot refrigerant

line? Keep in mind that this unit has a reverse

cycle and that different lines will be hot during the

“HEAT” and “COOL” cycles. Only two lines will

remain cool for all cycles - the line between the

compressor and the accumulator and the line

between the accumulator and the reversing valve.

INITIAL START-UP

1.

Supply power to the unit through the disconnect

switch prior to starting the compressor.

2.

Move the system switch on the room thermostat to

the “COOL” position, and lower its set point to

energize both the compressor and the reversing

valve. Cool air will be supplied to the conditioned

space.

3.

Check the compressor amperage. It should not

exceed the RLA rating printed on the unit data

plate or in Table 3 unless the ambient temperature

is above 105°F.

4.

Move the system switch on the room thermostat to

the “HEAT” position, and increase the set point of

the room thermostat until heating is required. The

compressor will run, but the reversing valve will be

de-energized. Warm air will be supplied to the con-

ditioned space.

5.

Check the operation of the indoor unit per Form

515.41-N2.

6.

Check the entire system for refrigerant leaks.

7.

Check for any abnormal noises and/or vibrations,

and make the necessary adjustments to correct

(e.g. fan blade touching shroud, refrigerant lines

hitting on sheet metal, etc.)

8.

After the unit has been operating for several min-

utes, shut off the main power supply at the discon-

nect switch and inspect all factory wiring

connections and bolted surfaces for tightness.

OPERATION

GENERAL

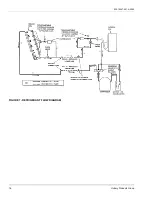

During the cooling cycle, when the reversing valve

solenoid becomes energized, operation will be the

same as any conventional air conditioning system.

During the heating cycle, when the reversing valve

solenoid becomes de-energized, compressor dis-

charge gas will be diverted to the indoor coil and the

outdoor coil will become the evaporator.

Refer to Figure 7 for illustration showing the flow of

refrigerant through a heat pump system.

SYSTEM SEQUENCE OF OPERATION

The following sequences of operation are based on

using the manual changeover thermostat. Refer to the

respective unit wiring diagram.

COOLING OPERATION

1.

The following controls will be energized through

terminal O on the thermostat to put the system in

the cooling mode.

• Relay RW and reversing valve solenoid.

2.

If the fan switch on the thermostat is in the “ON”

position, indoor section blower motor contactor

10M will be energized through terminal G to pro-

vide continuous blower operation. If the switch is in

the “AUTO” position, the blower will operate only

when the thermostat calls for cooling operation.

3.

When TC1 of the thermostat closes on a demand

for cooling, a circuit is made from terminal Y

through the defrost control board and safety

switches to energize contactor 1M and relay RY1,

starting the compressor. Contactor 2M is energized

through the NO contacts of RY1-1 and the NC con-

tacts of K2 on the defrost control board in order to

start the outdoor fan motor(s).

NOTE:

If discharge pressure falls below 180 PSI, PS

will open and de-energize No. 2 fan motor.

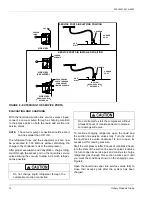

Reversing valves and check valves are precise

mechanical devices and will not tolerate any

mechanical abuse such as hammering. If a

refrigerant system isn't properly cleaned after a

compressor burn-out, scale may build up at

these devices and prevent them from operating

properly.