035-18547-001-A-0902

Unitary Products Group

19

4.

Relay RY1 also prevents the 10KW portion of

accessory electric heat referenced as standby

electric heat from being utilized whenever the com-

pressor is in operation. This part of the circuit is

covered under HEATING OPERATION.

5.

The thermostat will cycle the unit to satisfy the

cooling requirements of the conditioned space.

6.

After the unit has shutdown from a cooling cycle or

a power interruption, the anti-short cycle feature of

the defrost control board will not permit the unit to

restart for 5 minutes. This feature prevents the unit

from short cycling.

7.

If the discharge pressure reaches 430 psig, the HP

control will open and the defrost control board will

lock out the compressor. If the discharge tempera-

ture reaches 255°F, 2TH thermostat will open and

the defrost control board will lock out the compres-

sor. If the suction pressure falls to 7 psig, the low

pressure switch will open and the defrost control

will lock out the compressor.

8.

If the control that caused the lockout has automati-

cally reset, the unit can be restarted by one of the

following:

a.

Turning the system switch on the thermostat to the

“OFF” position and back to the “COOLING” position.

b.

Increasing the set point on the thermostat above the

temperature in the conditioned space and then

returning it to its original setting.

Opening and closing the power supply main disconnect

switch.

IN ALL THREE RESET METHODS DESCRIBED

ABOVE, A FIVE MINUTE TIME DELAY WILL TAKE

PLACE AFTER THE RESET BEFORE THE UNIT

WILL RESTART.

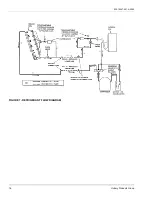

HEATING OPERATION

1.

Reversing valve is de-energized and the system

will be in the heating mode.

2.

If the fan switch on the thermostat is in the “ON”

position, indoor section blower motor contactor

10M will be energized through terminal G to pro-

vide continuous blower operation. If the switch is in

“AUTO” position, the blower will operate only when

thermostat calls for heating operation.

3.

When TH1 of the thermostat closes for first-stage

heat, a circuit is made from terminal Y through the

defrost control board and safety switches to ener-

gize contactor 1M and start the compressor. Con-

tactor 2M is energized through the NO contacts

RY1-1 which will start the outdoor fan motor(s).

NOTE:

If PS opens due to discharge pressure falling

below 180 PSI, the No. 2 fan motor will con-

tinue to operate through the NC contacts of

relay RW.

4.

The thermostat will cycle the unit to satisfy the

heating requirements of the conditioned space.

5.

After the unit has shutdown from a heating cycle or

a power interruption, the anti-short cycle feature of

the defrost control board will not permit the unit to

restart for 5 minutes. This feature prevents the unit

from short cycling.

6.

If the discharge pressure reaches 430 psig, the HP

control will open and the defrost control board will

lock out the compressor. If the discharge tempera-

ture reaches 255°F, 2TH thermostat will open and

the defrost control board will lock out the compres-

sor. If the suction pressure falls to 7 psig, the low

pressure switch will open and the defrost control

will lock out the compressor.

7.

If the control that caused the lockout has automati-

cally reset, the unit can be restarted by one of the

following:

a. Turning the system switch on the thermostat to

the “OFF” position and back to the “HEATING”

position.

b. Decreasing the set point on the thermostat

below the temperature in the conditioned space

and then returning it to its original setting.

c. Opening and closing the power supply main dis-

connect switch.

IN ALL THREE RESET METHODS DESCRIBED

ABOVE, A FIVE MINUTE TIME DELAY WILL TAKE

PLACE AFTER THE RESET BEFORE THE UNIT

WILL RESTART.

8.

Supplemental electric heat (if installed) will be con-

trolled by second stage TH2 of the thermostat. The

supplemental electric heat circuit is controlled

through low voltage terminals W, 60 and 66. The

standby portion of electric heat (controlled through