035-18547-001-A-0902

20

Unitary Products Group

low voltage terminal 53) cannot operate because

relay RY1 is energized, opening the circuit to termi-

nal 53, whenever the compressor is operating.

9.

When second stage heating TH2 is satisfied, the

supplemental heaters will be de-energized.

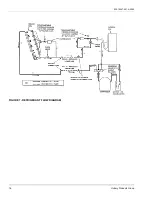

DEFROST CYCLE

When condensate freezes on the outdoor coil during

heating operation, it must be defrosted before it blocks

the flow of air across the coil.

1.

A defrost cycle will be initiated by the defrost con-

trol board's timed defrost feature.

2.

When the defrost cycle is initiated, the unit oper-

ates as follows:

a.

The reversing valve solenoid is energized through

the defrost control board causing the unit to switch

to the cooling cycle.

b.

Defrost control board de-energizes 2M contactor,

causing the outdoor section fan(s) to shut down.

c.

Supplemental electric heat (if installed) will be ener-

gized through defrost control board. Only that por-

tion of electric heat controlled through low voltage

control terminal 66 will be energized by the defrost

cycle. The operation of supplemental electric heat

during unit defrost will prevent cold drafts in the con-

ditioned space.

3.

The defrost cycle will be terminated when:

a. the liquid temperature exceeds 55°F, or

b. 10 minutes have passed since defrost initiation.

The 10 minute cycle time (independent of liquid line

temperature) is controlled by the defrost control board.

4.

At defrost termination, the unit returns to the nor-

mal heating operation.

OPERATION BELOW 0°F OUTDOOR TEMPERATURE

1.

At 0°F outdoor temperature, the low temperature

compressor cutoff thermostat 1TH contacts 1 and 3

will open, de-energizing contactor 1M which shuts

down the compressor. Contacts 1 and 2 of thermo-

stat 1TH are closed when contacts 1 and 3 are

open. This feature allows the standby electric heat

(if installed) to operate under control of first stage

heating TH1 of the room thermostat whenever the

compressor is shut-down by the 1TH control. The

supplemental electric heat will continue to be con-

trolled by the second stage TH2 of the room ther-

mostat same as described under Item 8 of

HEATING OPERATION.

2.

The indoor section blower operation will be con-

trolled by the first stage heating TH1 of the room

thermostat if the fan switch is in the “AUTO” posi-

tion.

EMERGENCY HEAT OPERATION

When the system switch on the room thermostat is

placed in the EMERGENCY HEAT position, operation

is as follows:

1.

The emergency heat light on the room thermostat

will be energized.

2.

Compressor will not operate because the Y circuit

of the room thermostat cannot be energized.

3.

Supplemental and standby electric heat (if

installed) will be controlled by first stage heating

TH1 of room thermostat.

4.

Indoor section blower will also be controlled by first

stage heating TH1 if fan switch is in the “AUTO”

position.

SAFETY FEATURES

1.

All outdoor fan motors have inherent protection

with automatic reset.

2.

Every compressor is internally protected against

excessive current and temperature by a line break

motor protector that is mounted inside the com-

pressor housing and is connected between each

winding and the common terminal.