271001-UIM-A-0407

Unitary Products Group

23

ADJUSTMENT OF TEMPERATURE RISE

The temperature rise, or temperature difference between the return air

and the heated supply air from the furnace, must be within the range

shown on the furnace rating plate and within the application limitations

as shown in Table 8.

After about 20 minutes of operation, determine the furnace temperature

rise. Take readings of both the return air and the heated air in the ducts,

about six feet (1.83 m) from the furnace where they will not be affected

by radiant heat. Increase the blower speed to decrease the temperature

rise; decrease the blower speed to increase the rise.

VARIABLE SPEED MOTORS

The variable speed motor must be configured so the blower will provide

a sufficient airflow so that the furnace operates within the temperature

rise range on the rating plate and within the application limitations

shown in Table 8 in these Instructions.

ADJUSTMENT OF FAN CONTROL SETTINGS

This furnace is equipped with a time-on/time-off heating fan control. The

fan-on delay is fixed at 30 seconds. The fan-off delay has 4 settings

(60, 90, 120 and 180 seconds). The fan-off delay is factory set to 120

seconds. The fan-off setting must be long enough to adequately cool

the furnace, but not so long that cold air is blown into the heated space.

The fan-off timing may be adjusted by positioning the jumper on two (2)

of the four (4) pins as shown in Figure 27.

Heating and Cooling Airflow

The heating and the cooling airflows are preset at the factory. The heat-

ing airflow is set to the maximum CFM. The cooling airflow is set to pro-

vide 90 percent of the maximum CFM. The heating and cooling airflows

must be field adjusted to match the HVAC system at installation. See

Table 16 for the HEAT, COOL and ADJ jumper settings to use for spe-

cific airflows.

Delay Taps Selection

The set of jumper pins on the control board labelled "DELAY" are used

to set the delay profiles for the furnace. These can be chosen so as to

maximize the comfort and sound levels for various regions of the coun-

try.

Tap A

is the default profile. It provides a 15-second ramp-up from zero

airflow to full capacity and a 15-second ramp-down from full capacity

back to zero airflow. Whenever there is a change in airflow mode, such

as from low heat to high heat, the motor will take 15 seconds to ramp

from one speed to the other.

Tap B

is the humid profile. This profile is best-suited for installations

where the humidity is frequently very high during cooling season, such

as in the southern part of the country. On a call for cooling, the blower

will ramp up to 50% of full capacity and will stay there for two (2) min-

utes, then will ramp up to 82% of full capacity and will stay there for five

(5) minutes, and then will ramp up to full capacity, where it will stay until

the wall thermostat is satisfied. In every case, it will take the motor 15

seconds to ramp from one speed to another.

Tap C

is the dry profile. This profile is best suited to parts of the country

where excessive humidity is not generally a problem, where the sum-

mer months are usually dry. On a call for cooling the motor will ramp up

to full capacity and will stay there until the thermostat is satisfied. At the

end of the cooling cycle, the blower will ramp down to 50% of full capac-

ity where it will stay for 60 seconds. Then it will ramp down to zero. Any

ramp up to a higher speed will take 30 seconds and any ramp down to a

lower speed (or off) will take 60 seconds.

Tap D

is the normal profile, best suited for most of the country, where

neither excessive humidity nor extremely dry conditions are the norm.

On a call for cooling, the motor will ramp up to 63% of full capacity and

will stay there for 90 seconds, then will ramp up to full capacity. At the

end of the cooling cycle, the motor will ramp down to 63% of full capac-

ity and will stay there for 30 seconds, then will ramp down to zero. In

every case, it will take the motor 15 seconds to ramp from one speed to

another.

The temperature rise, or temperature difference between the return

air and the supply (heated) air from the furnace, must be within the

range shown on the furnace rating plate and within the application

limitations shown in Table 8 “RATINGS & PHYSICAL/ELECTRICAL

DATA”.

The supply air temperature cannot exceed the “Maximum Supply

Air Temperature” specified in these instructions and on the fur-

nace rating plate. Under NO circumstances can the furnace be

allowed to operate above the Maximum Supply Air Temperature.

Operating the furnace above the Maximum Supply Air Temperature

will cause premature heat exchanger failure, high levels of Carbon

Monoxide, a fire hazard, personal injury, property damage, and/or

death.

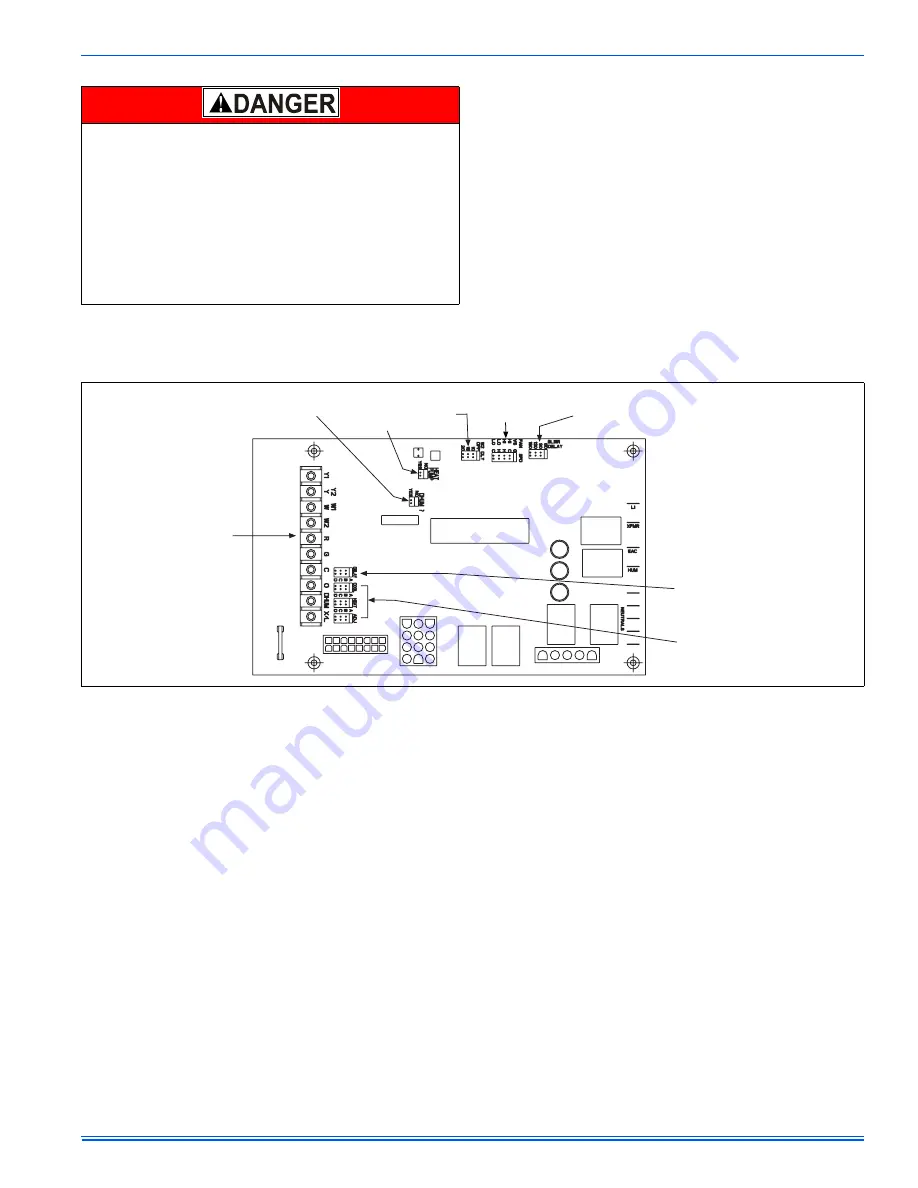

FIGURE 27:

Furnace Control Board

CONTINUOUS

FAN SPEED

JUMPER

BLOWER

OFF DELAY

JUMPER

HI HEAT

DELAY

JUMPER

HEAT

DELAY

JUMPER

DEHUMIDISTAT

JUMPER

LOW

VOLTAGE

TERMINALS

BLOWER

SPEED

JUMPERS

COOLING

PROFILE

JUMPER