271001-UIM-A-0407

Unitary Products Group

9

IMPORTANT:

An accessible manual shutoff valve must be installed

upstream of the furnace gas controls and within 6 feet (1.8 m) of the fur-

nace.

The furnace must be isolated from the gas supply piping system by

closing its individual external manual shutoff valve during any pressure

testing of the gas supply piping system at pressures equal to or less

than 1/2 psig (3.5 kPa).

Gas piping may be connected from either side of the furnace using any

of the gas pipe entry knockouts on both sides of the furnace. Refer to

Figure 1 dimensions.

GAS ORIFICE CONVERSION FOR PROPANE (LP)

This furnace is constructed at the factory for natural gas-fired operation,

but may be converted to operate on propane (LP) gas by using a fac-

tory-supplied LP conversion kit. Follow the instructions supplied with

the LP kit. Refer to Table 6 or the instructions in the propane (LP) con-

version kit for the proper gas orifice size.

HIGH ALTITUDE GAS ORIFICE CONVERSION

This furnace is constructed at the factory for natural gas-fired operation

at 0 – 8,000 feet (0-m – 2,438 m) above sea level.

The manifold pressure must be changed in order to maintain proper

and safe operation when the furnace is installed in a location where the

altitude is greater than 8,000 feet (2,438 m) above sea level. Refer to

Tables 6 and 7 for proper manifold pressure settings.

HIGH ALTITUDE PRESSURE SWITCH CONVERSION

For installation where the altitude is less than 8,000 feet (2,438 m), it is

not required that the pressure switch be changed. For altitudes above

8,000 feet (2,438 m), see Table 17 Field Installed Accessories - High

Altitude Pressure Switch

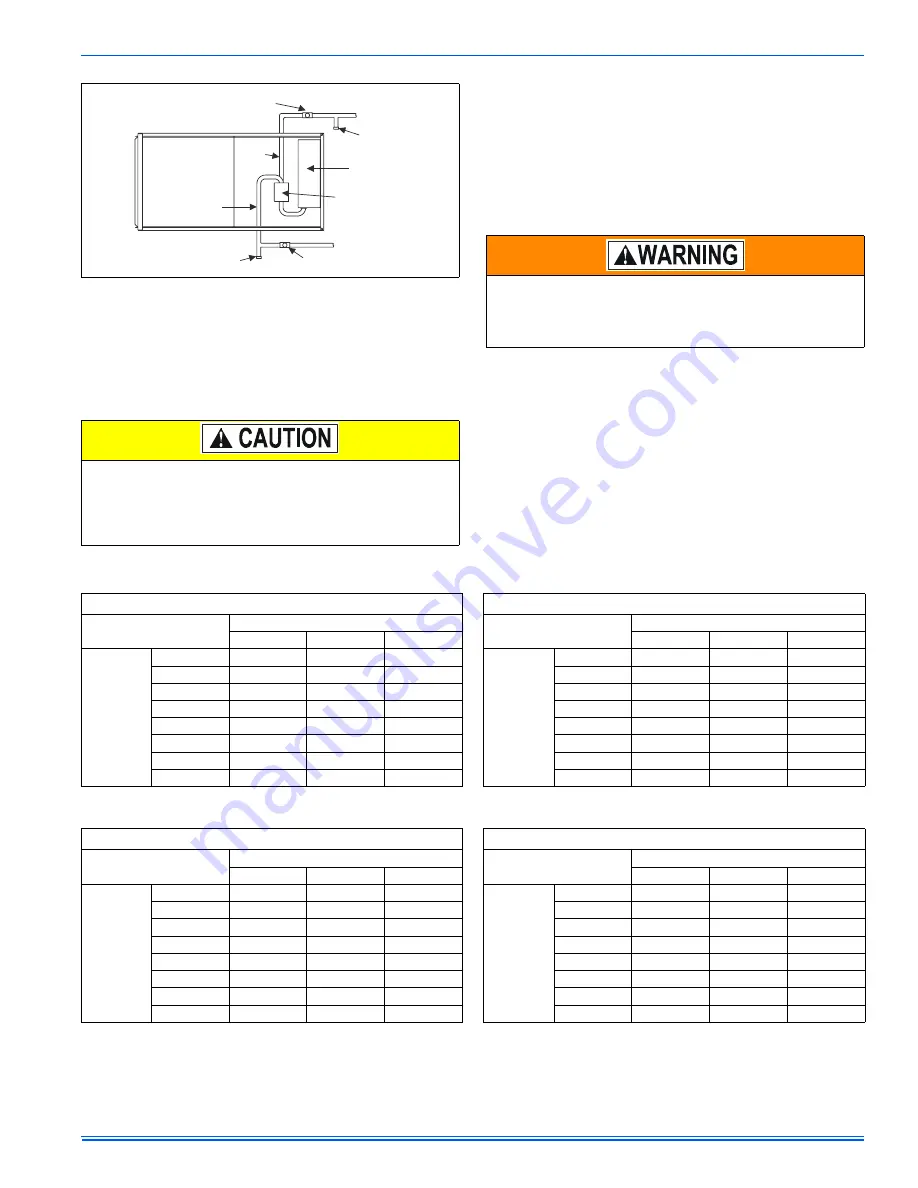

FIGURE 7:

Horizontal Gas Piping

The gas valve body is a very thin casting that cannot take any

external pressure. Never apply a pipe wrench to the body of the gas

valve when installing piping. A wrench must be placed on the octag-

onal hub located on the gas inlet side of the valve. Placing a wrench

to the body of the gas valve will damage the valve causing improper

operation and/or the valve to leak.

MANUAL

SHUT-OFF

VALVE

GAS

PIPE

GAS

PIPE

DRIP

LEG

MANUAL

SHUT-OFF VALVE

GAS VALVE

GAS BURNERS

DRIP

LEG

LoNOx furnaces requiring propane (LP) gas must have the LoNOx

screens removed prior to installation and operation. See the

instructions supplied with the propane conversion kit or the start up

procedure at the back of these instructions on proper removal of the

NOx screens.

TABLE 6:

Nominal Manifold Pressure - High Fire

Single/Second Stage Manifold Pressures (in wc)

Single/Second Stage Manifold Pressures (kpa)

Altitude (feet)

Altitude (m)

0-7999

8000-8999

9000-9999

0-2437

2438-2742

2743-3048

Ga

s He

at

in

g V

a

lu

e

(B

TU/c

u f

t.)

800

3.5

3.5

3.5

Ga

s He

at

in

g V

a

lu

e

(MJ

/cu m)

29.8

0.87

0.87

0.87

850

3.5

3.5

3.5

31.7

0.87

0.87

0.87

900

3.5

3.5

3.5

33.5

0.87

0.87

0.87

950

3.5

3.5

3.3

35.4

0.87

0.87

0.81

1000

3.5

3.2

2.9

37.3

0.87

0.80

0.73

1050

3.5

2.9

2.7

39.1

0.87

0.73

0.67

1100

3.2

2.7

2.4

41.0

0.80

0.66

0.61

2500 (LP)

9.8

8.2

7.5

93.2 (LP)

2.44

2.03

1.86

TABLE 7:

Nominal Manifold Pressure - Low Fire

First Stage Manifold Pressures (in wc)

First Stage Manifold Pressures (kpa)

Altitude (feet)

Altitude (m)

0-7999

8000-8999

9000-9999

0-2437

2438-2742

2743-3048

Ga

s Hea

tin

g V

a

lue

(B

T

U

/c

u

f

t.)

800

1.7

1.7

1.7

Ga

s Hea

tin

g V

a

lue

(M

J/

cu

m)

29.8

0.42

0.42

0.42

850

1.7

1.7

1.7

31.7

0.42

0.42

0.42

900

1.7

1.7

1.7

33.5

0.42

0.42

0.42

950

1.7

1.7

1.5

35.4

0.42

0.42

0.38

1000

1.6

1.5

1.4

37.3

0.41

0.37

0.34

1050

1.5

1.4

1.3

39.1

0.37

0.34

0.31

1100

1.3

1.2

1.1

41.0

0.34

0.31

0.28

2500 (LP)

4.1

3.8

3.5

93.2 (LP)

1.03

0.95

0.87