8

FURNACE SIZING AND DUCT SYSTEM

DESIGN

The duct system must be installed in conformance

with ASHRAE/NFPA 90, Standard for Installation of

Warm Air Heating and Air Systems and other

applicable local codes. Failure to adhere to proper

duct system design standards can reduce airflow,

resulting in reduced system performance and

possible furnace damage.

Consideration should be given to the heating

capacity required and also to the air quantity (CFM)

required if A/C is to be installed along with the

furnace or at some future time. These factors can be

determined by calculating the heat loss and heat

gain of the home or structure.

If these calculations are not performed and the

furnace is oversized, the following may result:

1. Short cycling of the furnace.

2. Wide temperature fluctuations from the thermo-

stat setting.

3. Reduced overall operating efficiency of the

furnace.

The supply and return duct system must be of

adequate size and designed such that the furnace

will operate within the designed air temperature rise

range and not exceed the maximum designed static

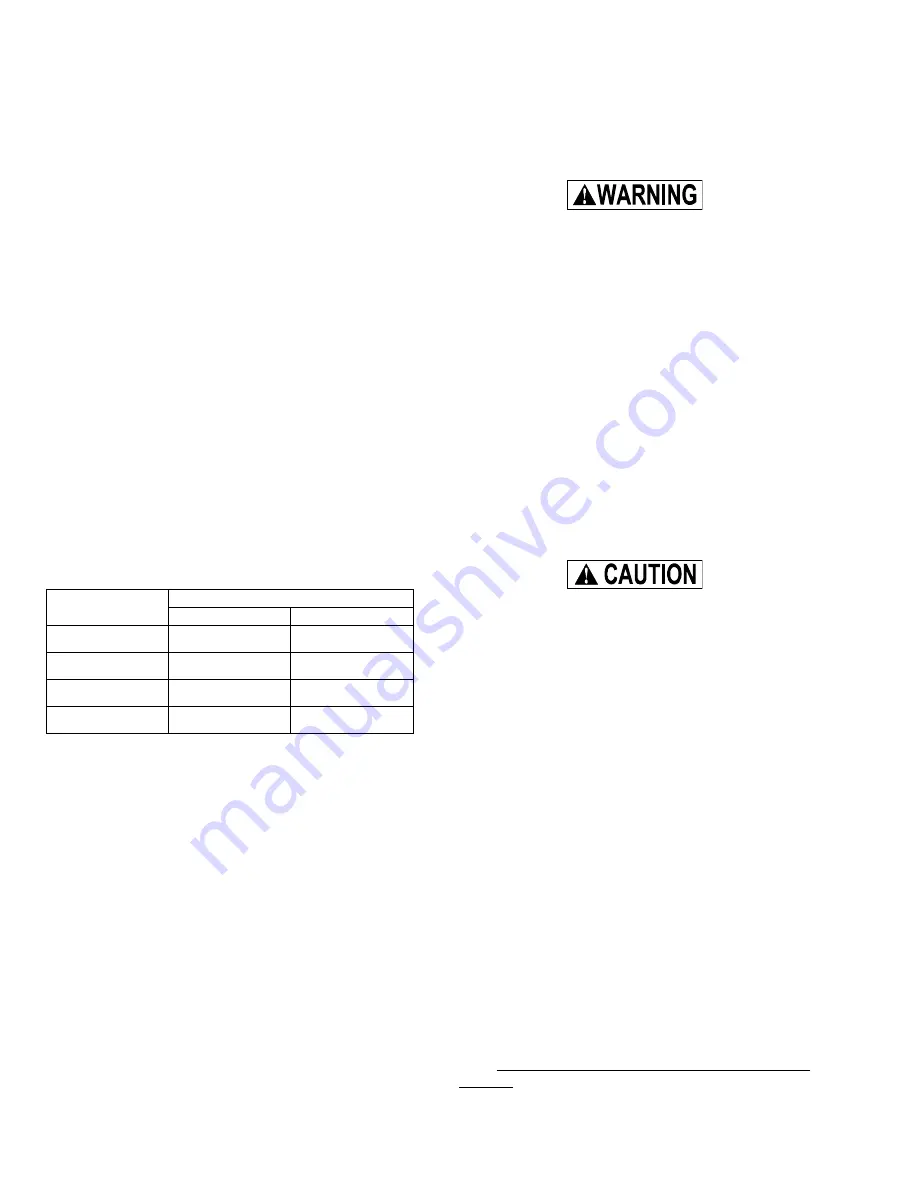

pressure. These values are listed in the table below.

EXT. STATIC IN. W.C.

INPUT BTUH

MINIMUM

MAXIMUM

50,000

.10

.50

75,000

.12

.50

100,000

.15

.50

125,000

.20

.50

Additional information, values and data necessary

for heat loss, heat gain and duct system design may

be found in the ASHRAE HANDBOOK OF FUNDA-

MENTALS or in other nationally recognized publica-

tions recognized by municipal, state, provincial and

federal code authorities.

If possible, it is recommended that the supply air

duct attached to the furnace be provided with a

removable access panel. The opening should be

accessible when the furnace is installed in service

and should be large enough that smoke or reflected

light may be observed inside the casing to indicate

the presence of leaks in the heat exchanger. The

cover panel for this opening should be attached in

such a manner as to prevent leaks.

A/C Usage Duct Systems

1. When a single (common) duct system is used,

one of the following methods shall be used:

a. A plenum type cooling coil must be installed

on the air discharge side, or

b. A blower-coil type cooling coil must be in-

stalled in parallel with and isolated from the

furnace, or

c. A self-contained A/C unit must be in parallel

with and isolated from the furnace.

Dampers must be installed when coil-blower

or self-contained unit is employed to pre-

vent conditioned cool air from coming in

contact with the heat exchanger to avoid

moisture condensation and rust-out. This

can allow products of combustion to be cir-

culated into the living area by the furnace

blower resulting in possible asphyxiation. If

dampers are of a manually operated type, a

means must be provided to prevent either

the furnace or A/C unit from operating un-

less dampers are in full heat or cool posi-

tion.

If two duct systems are used as could be the case

with a coil-blower or a self-contained A/C unit, the

furnace and A/C unit should be controlled by a

single combination heating and cooling thermostat

which will prevent the furnace and A/C unit from

operating simultaneously.

If a separate heating and separate cooling

thermostat is used, a manually operated

electrical interlock switch must be installed

to prevent simultaneous operation of both

systems and to avoid a possible hazardous

condition due to overheating of the condi-

tioned space.

RETURN AIR AND FILTERS

Return Air Temperature

This furnace design is to be operated in normal

household temperatures. The continuous return air

temperature must not be below 60°F or above 85°F.

Return Air Connection – Upflow

The return air may be brought in through the bottom

of the furnace or through one or both sides of the

furnace casing. The furnace casing may be cut out

so that side return air connections may be used. The

furnace is supplied with flanges on the top of the

furnace to which the return air duct may be fastened.

The casing top is embossed to indicate where to

bend the flanges. If a side return is to be used, cut

out the side of the casing 14" high by 16 1/4" wide

using the lances in the casing side as a guide. DO

NOT CUT THE OPENING LARGER THAN 14"x 16

1/4". It is not permissible to cut out the back of the

furnace.